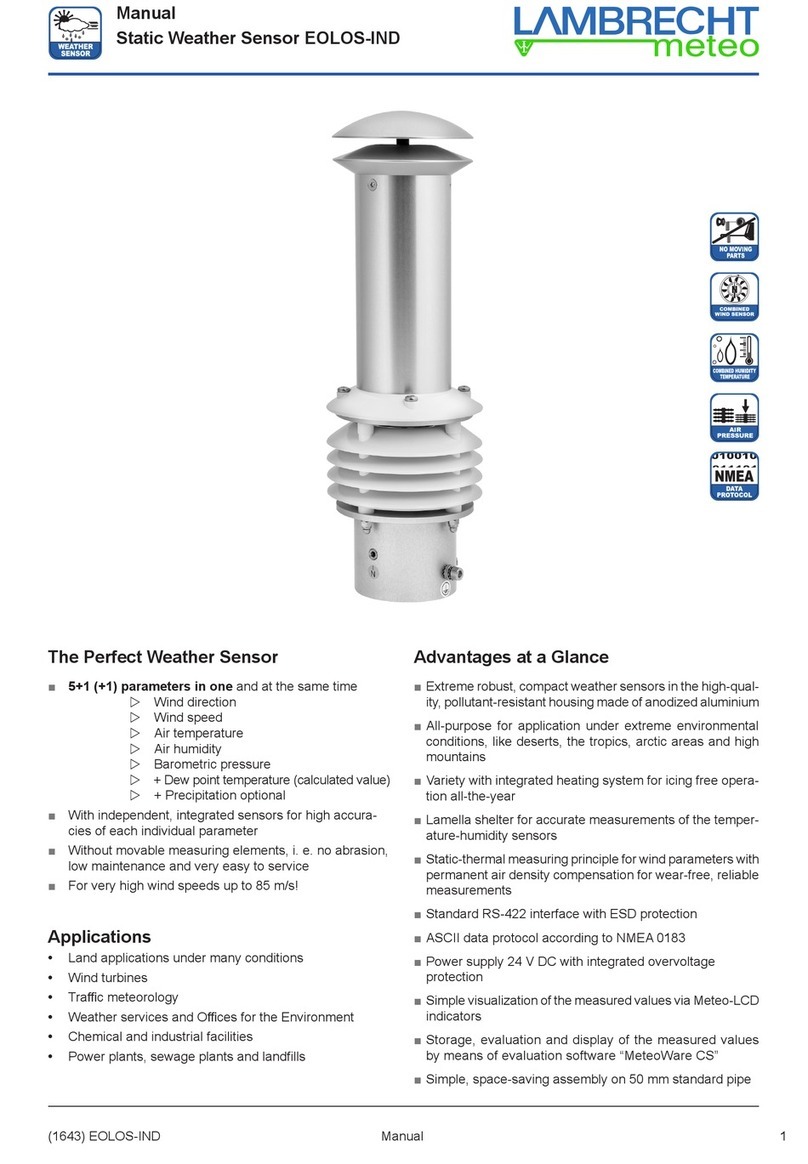

Manual

Wind Sensors EFFICIENT Modbus (14579)

(14579) EFFICIENT Modbus Manual

Please note that the cable on the data processing side is pro-

tected against moisture, e.g. by using suitable cable glands.

If the mast is prepared accordingly, the connection cable can

also be laid completely in the pipe sections of a mast.

To reduce the risk of inductive interference the

sensor must be properly grounded (screening

on both sides).

5 Heating

The sensor has an electronically controlled 18 watt heating

in the sensor head. The heating is powered along with the

electronics of the sensor.

Under most climatological condi-

tions the heating prevents blocking

of the moving sensor parts (see

illustration). The cup rotor or the

wind vane are not heated. In case

of icing or formation of ice at the

moving sensor element the func-

tion is restricted for the period of

icing.

6 Maintenance

The sensor design permits long periods of maintenance-free

operation. We therefore recommend a regular visual verica-

tion of the north setup of the wind direction sensor as well as

a sensor calibration of both sensor types in the distance of

2 years.

When you install the connecting cables make sure

not to excessively shorten the cable leading to the

connector in the lower part of the sensor casing so

that you can later maintain or dismounting the sensor.

Put further a cable loop as sensor protection against

water under the sensor.

Tip: Install the sensors on ground to the traverse and

align you the wind vane parallel to the traverse. You

go only then upward, in order to accordingly align the

sensors with traverse under assistance of a partner

on ground.

3 Setting up the North direction

of the wind direction sensor

For wind direction measurements the North mark on the sen-

sor must be aligned with the geographical north direction.

You have to turn the marking exactly over the marking at the

sensor shaft. When you have aligned the marks, you may x

the wind vane with e.g. a piece of adhesive tape. When you

have xed the wind vane this way you can locate the refer-

ence point by aiming at it over the axis. Now you must turn the

sensor casing on the mounting tube until the tip of the wind

vane points to the reference point in the north.

To set up the sensor’s north orientation select a landmark

which is as far as possible up north with regard to the nal

position of the wind direction sensor.

The reference point can be selected using a topographical

map (1:25000). The exact position of the reference point is

determined using an amplitude compass that can be adjusted

horizontally on a stand.

Please make sure there is no magnetic deviation

of the compass.

When the North direction is set up for the wind direction sen-

sor, you can mounting it like under point "Principle of installa-

tion". Remove any adhesive tape.

If you cannot select a northern reference point owing to local

conditions, you can proceed analogously using a reference

point in the south. In this case, however, you have to make

sure the north mark on the sensor does not point to the refer-

ence point but in the opposite direction.

4 Electrical connection

Wind sensors EFFICIENT Modbus are connected to a data

measuring system via the open cable end. The sensors have

a cable-plug connection to the cable.

The connecting cable is suitably led along the mast between

the data evaluation device (indicating instrument or data ac-

quisition system) and the sensor. The cable must be fastened

using appropriate cable ties (their length depends on the mast

diameter).

Lead the cable in a wide curve from the mast to the

bottom of the casing so that you can later easily

dismount the cable.

H

Heating

Heizung

4