BOX 422 • TOWER, MN 55790 • USA • Tel (218) 753-2330 • www.lamppakuuma.com

3

INTRODUCTION

Your Vapor-Fire Model 100 by Lamppa Manufactur-

ing and Distributing Co., Inc., is a highly-sophisticat-

ed, electronically-controlled, solid fuel furnace utiliz-

ing the latest space-age technology. If installed and

operated properly it should give you years of satis-

fying heat. Please read all of the instructions before

installing and operating your new Vapor-Fire Model

100.

We ask that you contact your sales person and ar-

range for a professional installation.

Installation must be done by a qualified installer.

LIMITED WARRANTY

Your basic Vapor-Fire Model 100 is warranted for

twenty-ve (25) years from the date of purchase by

Lamppa Manufacturing and Distributing Co., Inc., if it

is installed and maintained according to the instruc-

tions provided by the manufacturer. This warranty is

voided if the Vapor-Fire 100 is used to burn materials

for which the unit is not certied by the EPA, and void

if not operated according to the owner’s manual.

Under this warranty the manufacturer will repair de-

fects in workmanship and replace defective parts

free of charge to the customer. Any repairs that might

require welding, burning, patching, etc., that is nor-

mally done in the manufacturer’s plant, the customer

shall ship the furnace, freight prepaid, to the plant at

no cost to Lamppa Manufacturing and Distributing

Co., Inc.

This warranty does not apply to any heat shields,

brick holders, or parts, such as seals, latches, hing-

es, other moving parts that wear out under normal

usage.

Under this warranty, all electrical components are

covered for a period of 90 days from date of pur-

chase if installed according to the manufacturer’s

instructions. The customer shall provide to the man-

ufacturer, proof of purchase. Any repairs or replace-

ment of components shall have a prior agreement

between the customer and the manufacturer, before

any such action is undertaken.

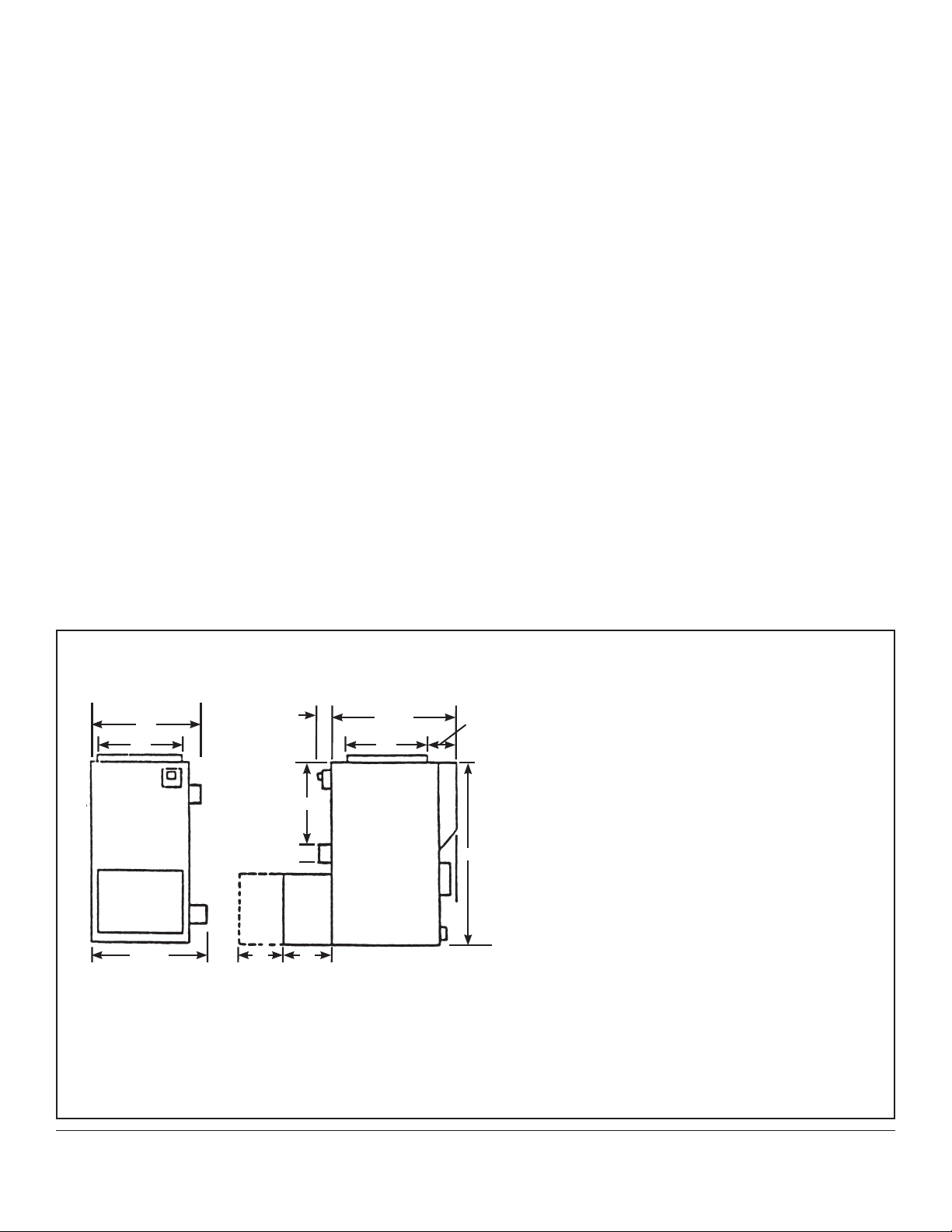

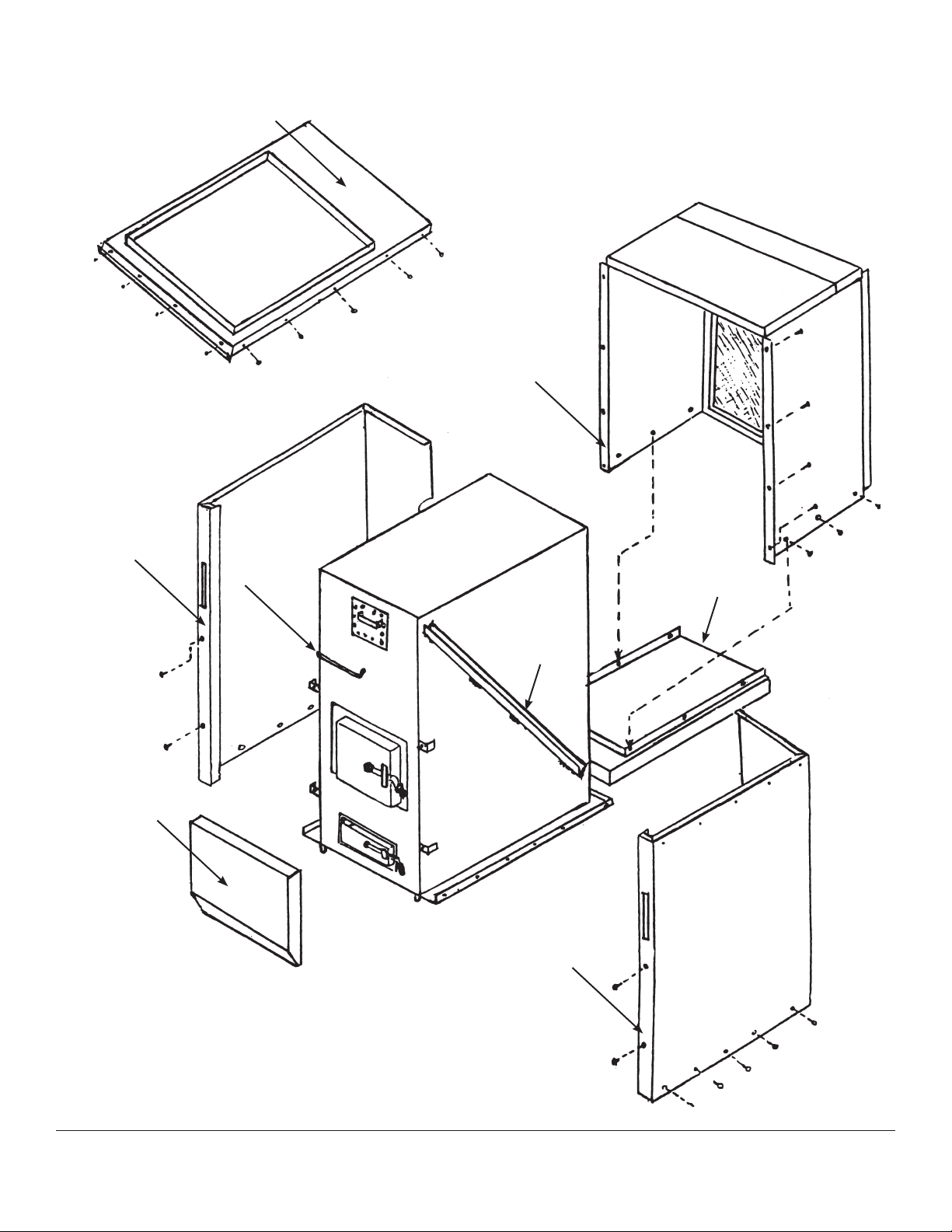

Dimensions ................................ 51.5” H x 27” W x 52.25” D

Flue Size.............................................................. 6” Diameter

Heat Outlet Size...................................................... 24” x 24”

Fire Door Opening........................................... 12” W x 12” H

Control Type........................................................... Electronic

Ash Drawer Size....................................19” L x 10” W x 3” D

Combustion Chamber .....................23” L x 15.5” W x 20” H

Maximum Wood Length ...................................................22”

Combustion Chamber Lining......... Brick Liner and Cast Iron

Fan Limit Control.............................Honeywell L 4064B2210

Fan Low Limit.....................................White Rogers 3F01-33

24 Volt Honeywell Thermostat...............................T87K1007

Fan Relay ....................................... Honeywell R8239A 1052

Electronic Draft Control ............... Vapor Fire Model 100/200

Draft Requirement........................................ .03” - .06” W.C.

Filter............................................................. 14” x 24” x 1” (2)

Cold Air Return ............................................... 22” W x 26” H

Power Req’d .....15 amps, 120 volt, 60 Hz No. 14 AWG wire

Clearance to Combustible

Side .....................................................................................6”

Front ..................................................................................48”

From the Flue Pipe............................................................18”

Weight ................................................................. 695 pounds

Fuel Type ............................................................... Wood only

Chimney Requirement ....................................... 6” Class “A”

SPECIFICATIONS

Figure 1

27” 34.25”

24” 24”

30.75” 10” 18”

4.5”

2”

51.5”

6”

15.5”

Your Vapor-Fire Model 100 furnace is warranted for

(10) years against defects in materials and workman-

ship from the date of purchase, except for electrical

components and the blower, which carry a (1) year

manufacture warranty. Warranty does not apply to

re-bricks, seals, latches, hinges, or other moving

parts subject to normal wear and tear.

The manufacturer’s warranty extends only to the orig-

inal purchaser, applies to normal residential use, and

is not transferable.

The furnace must be installed, maintained, and op-

erated according to the Manufacturer’s Operator’s

Instructions. The warranty is voided if the Vapor-Fire

100 is used to burn materials not certied by the EPA

and not operated according to the owner’s instruc-

tions.

Upon obtaining authorization, returned products are

to be shipped prepaid to the manufacturer. Transpor-

tation fees to ship the product back to the purchaser

will be paid by the manufacturer.

This warranty applies to products purchased after

September 1st, 2021.