Table of Contents

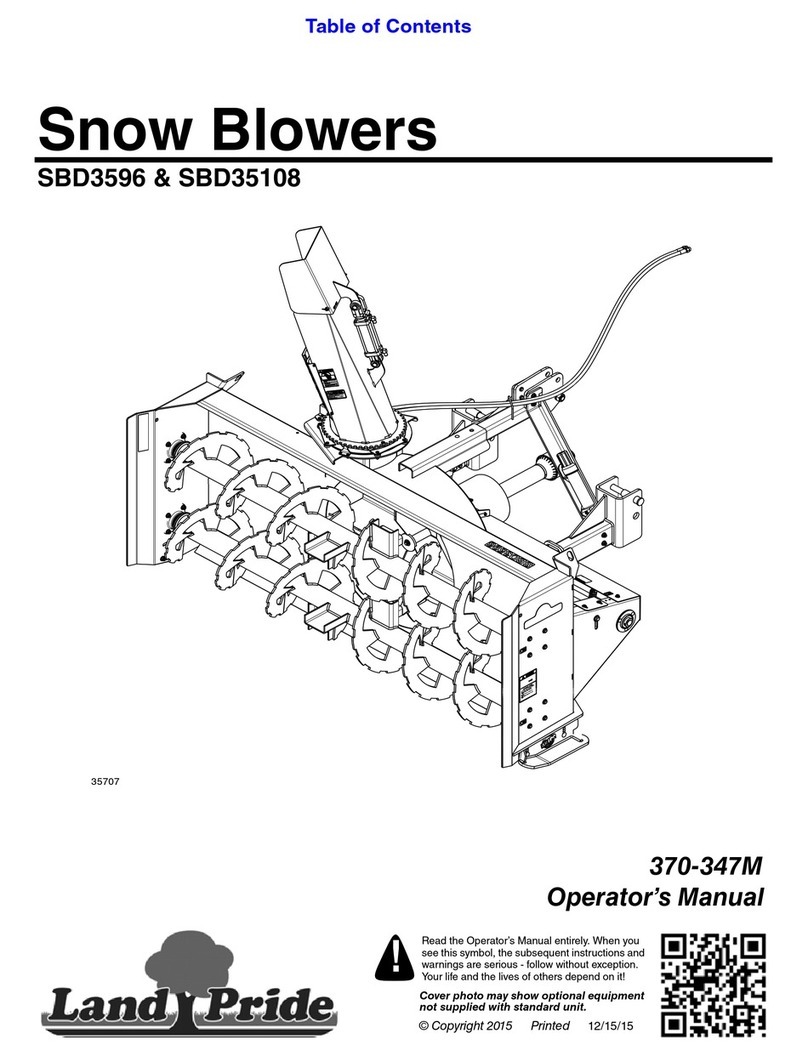

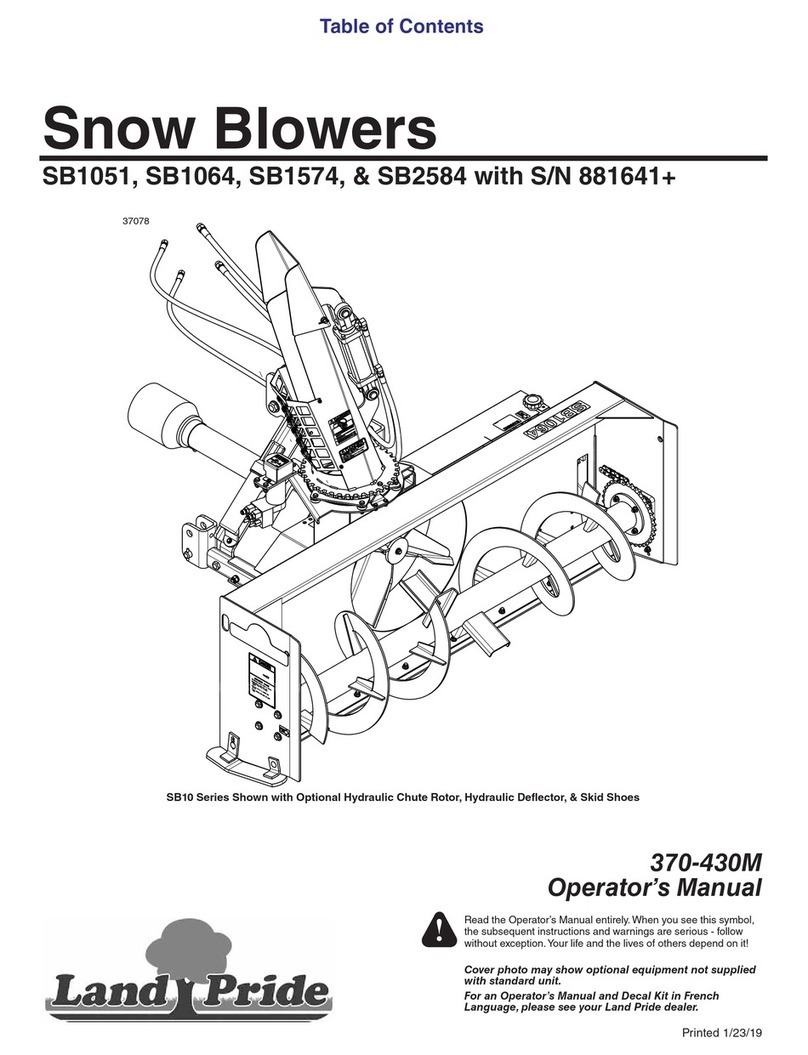

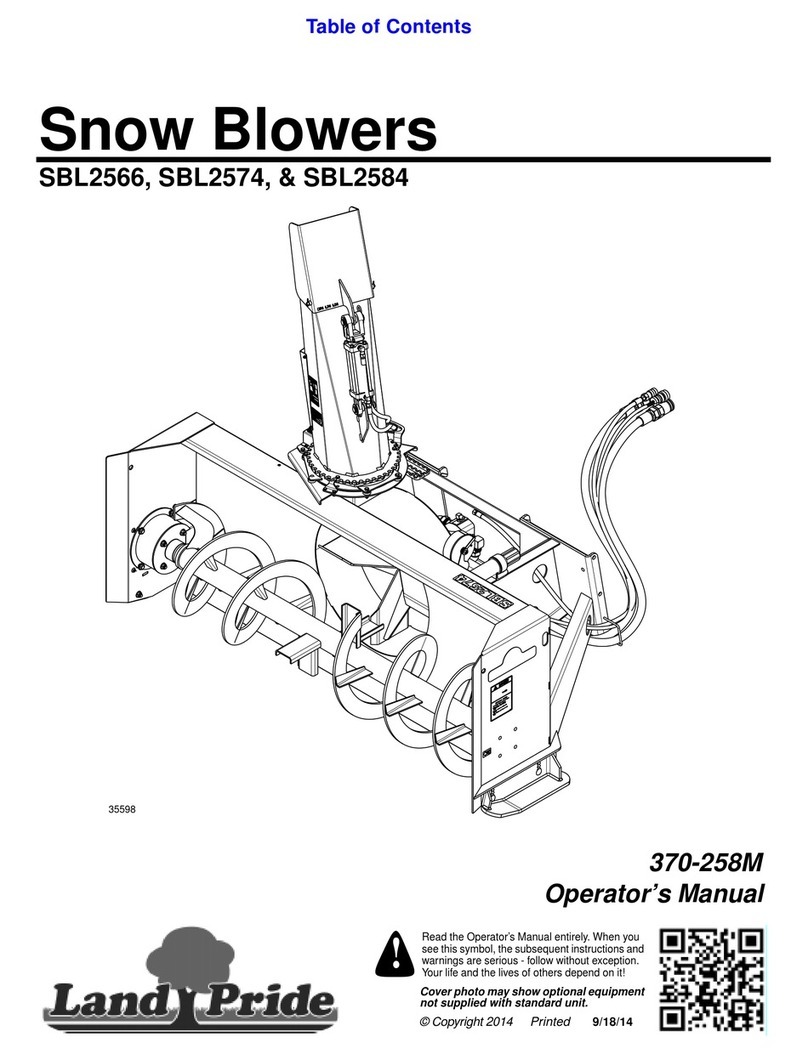

SB1051, SB1064, SB1574, & SB2584 with S/N 881641+ Snow Blowers 370-430M 10/12/16

© Copyright 2016 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparation of this manual, Land Pride assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use

of the information contained herein. Land Pride reserves the right to revise and improve its products as it sees fit. This publication describes the state of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . . . 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

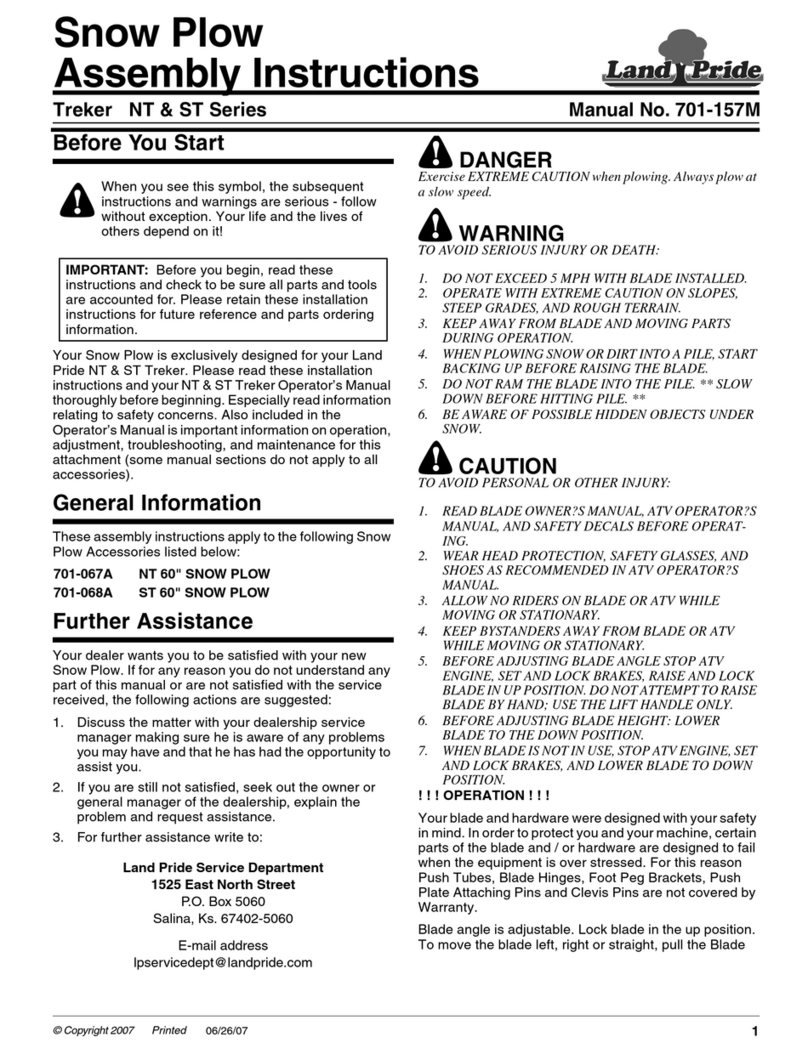

Section 1: Standard Assembly & Set-up . . . . 8

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . . 8

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . 8

Dealer Set-up Instructions . . . . . . . . . . . . . . . . . . . . 8

Loading & Unloading . . . . . . . . . . . . . . . . . . . . . . 8

SB10 Chute Assembly . . . . . . . . . . . . . . . . . . . . . . 9

SB15 & 25 Chute Assembly . . . . . . . . . . . . . . . . . . 9

Section 2: Optional Assembly & Set-up . . . . 10

Manual Chute Rotation . . . . . . . . . . . . . . . . . . . . . 10

Sprocket Adjustment . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic Chute Rotation . . . . . . . . . . . . . . . . . . . 11

Electric Chute Rotation . . . . . . . . . . . . . . . . . . . . . 11

Hydraulic Deflector Assembly . . . . . . . . . . . . . . . . 12

Electric Deflector Assembly . . . . . . . . . . . . . . . . . . 12

Manual Deflector Assembly . . . . . . . . . . . . . . . . . . 13

Skid Shoes, Outer . . . . . . . . . . . . . . . . . . . . . . . . . 13

Skid Shoes, Inner . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wear Bar, Lower . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wear Bars, Outer . . . . . . . . . . . . . . . . . . . . . . . . . 14

Extend/Retract 3-Point Hitch Frame . . . . . . . . . . . 15

Section 3: Tractor Hook-up & Unhook . . . . . 16

Tractor Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Leveling The Snow Blower . . . . . . . . . . . . . . . . . . 17

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 17

Check Driveline Collapsible Length . . . . . . . . . . 17

Shorten Driveline . . . . . . . . . . . . . . . . . . . . . . . . 18

Check Driveline Maximum Length . . . . . . . . . . . 18

Check Driveline Interference . . . . . . . . . . . . . . . 18

Hydraulic Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Motor For Chute Rotation . . . . . . . . . . 19

Hydraulic Cylinder For Deflector Adjustment . . . 19

Electrical Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unhooking Snow Blower . . . . . . . . . . . . . . . . . . . . 20

Section 4: Adjustments . . . . . . . . . . . . . . . . . 21

Hitch Pin Locations . . . . . . . . . . . . . . . . . . . . . . . . 21

Standard 3-Point & Quick Hitch Hook-up . . . . . . 21

Special 3-Point Hook-up . . . . . . . . . . . . . . . . . . . 21

Special Quick Hitch Hook-up . . . . . . . . . . . . . . . 21

Chute Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual Rotation . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electric Motor Rotation . . . . . . . . . . . . . . . . . . . . 22

Hydraulic Motor Rotation . . . . . . . . . . . . . . . . . . 22

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual Adjusting . . . . . . . . . . . . . . . . . . . . . . . . 22

Electric Actuator Adjusting . . . . . . . . . . . . . . . . . 22

Hydraulic Cylinder Adjusting . . . . . . . . . . . . . . . . 22

Inner Skid Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Outer Skid Shoes . . . . . . . . . . . . . . . . . . . . . . . . . 23

Outer Wear Bars . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Drive Chain Take-up . . . . . . . . . . . . . . . . . . . . . . . 24

Section 5: Operating Instructions . . . . . . . . . 25

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . 25

Inspection Procedures . . . . . . . . . . . . . . . . . . . . . . 25

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 26

General Operator Instructions . . . . . . . . . . . . . . . . 28

Section 6: Maintenance & Lubrication . . . . . 30

General Maintenance Information . . . . . . . . . . . . . 30

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . . . 30

Auger & Impeller Inspection . . . . . . . . . . . . . . . . . . 30

Shearbolt Protection . . . . . . . . . . . . . . . . . . . . . . . 31

Drive Shaft Shearbolt . . . . . . . . . . . . . . . . . . . . . 31

Driveline Shearbolt . . . . . . . . . . . . . . . . . . . . . . . 31

Chute Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Inner Skid Shoes (Optional) . . . . . . . . . . . . . . . . . . 32

Outer Skid Shoes (Optional) . . . . . . . . . . . . . . . . . 33

Outer Wear Bars (Optional) . . . . . . . . . . . . . . . . . . 33

Lower Wear Bar (Optional) . . . . . . . . . . . . . . . . . . 34

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . 34

Ordering Replacement Parts . . . . . . . . . . . . . . . . . 34

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Shearbolt Sprocket Hub . . . . . . . . . . . . . . . . . . . 35

Auger Flange Bearings . . . . . . . . . . . . . . . . . . . . 35

Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Driveline U-joints . . . . . . . . . . . . . . . . . . . . . . . . 36

Driveline Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Section 7: Specifications & Capacities . . . . . 37

Section 8: Features & Benefits . . . . . . . . . . . 39

Section 9: Torque Values Chart . . . . . . . . . . 40

Section 10: Warranty . . . . . . . . . . . . . . . . . . . 41