7

Introduction

12/14/01

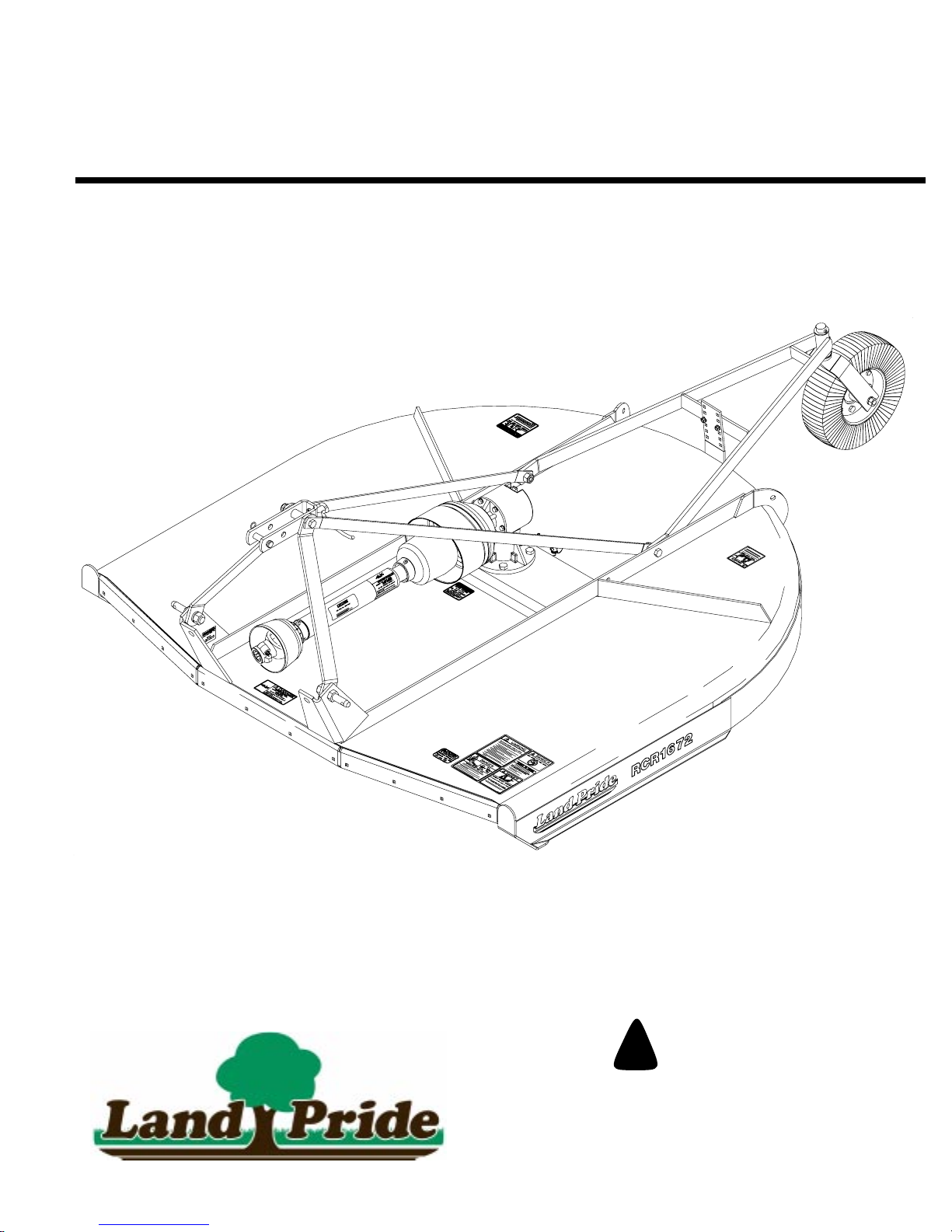

RCR16 Series Rotary Cutters 312-742M

Land Pride

Introduction

Owner Assistance

The Warranty Registration card should be filled out by the

dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repair parts are required contact a

Land Pride dealer. A dealer has trained personnel, repair

parts and equipment needed to service the implement.

Theparts onyourRCR16 SeriesRotary Cutterhave been

specially designed and should only be replaced with

genuine Land Pride parts. Therefore, should your Rotary

Cutter require replacement parts go to your Land Pride

Dealer.

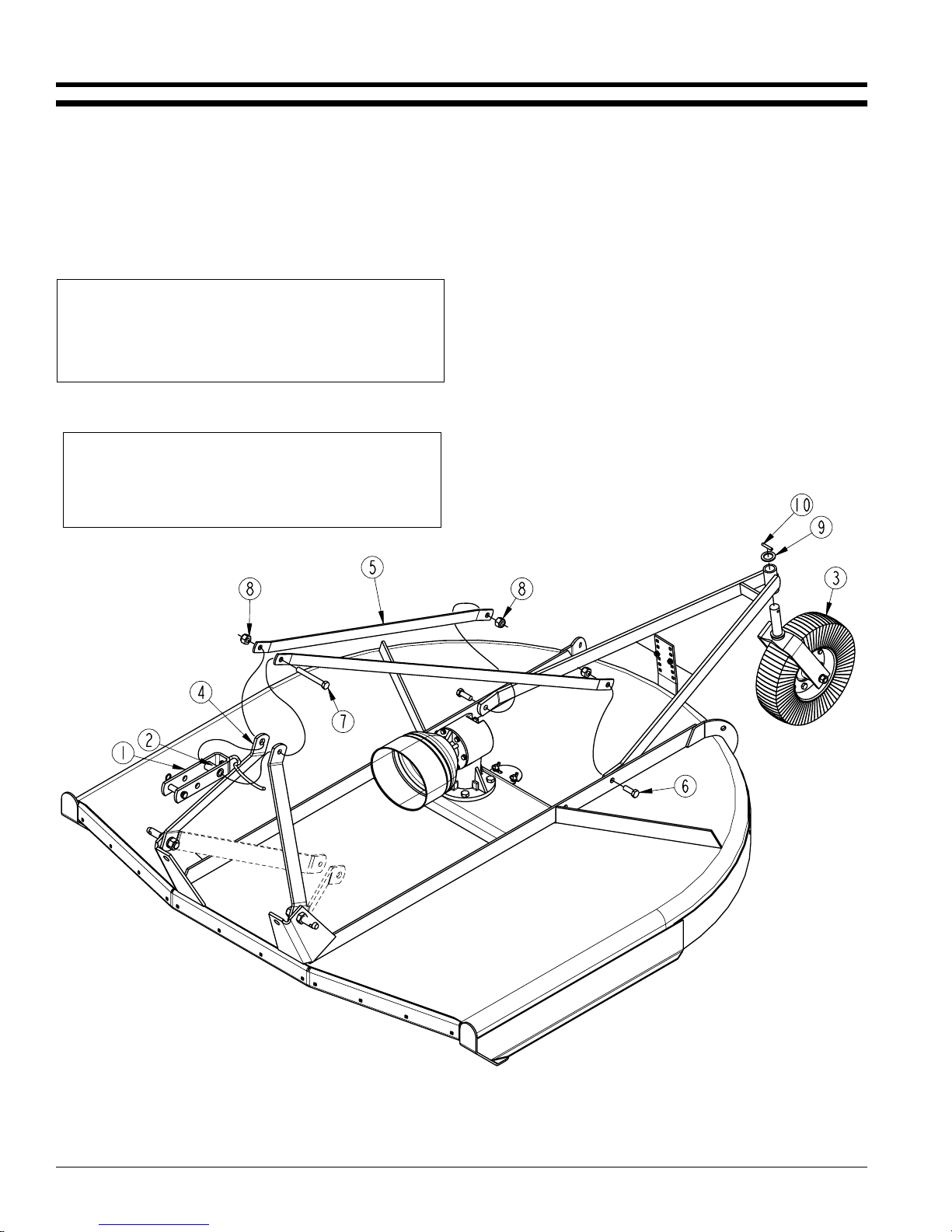

Serial Number Plate

For prompt service always use the serial number and

model number when ordering parts from your Land Pride

dealer.Besuretoincludeyourserialandmodelnumbersin

correspondence also. Refer to Figure 1 for the location of

your serial number plate.

Further Assistance

YourdealerwantsyoutobesatisfiedwithyournewRotary

Cutter.Iffor any reasonyoudo not understandanypart of

this manual or are not satisfied with the service received,

the following actions are suggested:

1. Discuss the matter with your dealership service

manager making sure he is aware of any problems

you may have and that he has had the opportunity to

assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

Land Pride

Service Department

P.O. Box 5060

Salina, KS 67402-5060

Serial Number Plate Location

Figure 1

19745

Land Pride welcomes you to the growing family of new

product owners.

This Rotary Cutter has been designed with care and built

by skilled workers using quality materials. Proper

assembly, maintenance, and safe operating practices will

help you get years of satisfactory use from the Rotary

Cutter.

Application

Land Pride’s RCR16 Series Rotary Cutters are ideal for

clearing grass, weeds and light brush. These cutters offer

fast, clean, dependable mowing and have been

extensively tested to ensure operating safety. High blade

tip speeds assure a clean cut in a variety of field

conditions. The standard stump jumper slides over

stumps, rocks and debris and safety guards help contain

material under the deck. See “Features and Benefits”,

“Section 5” for additional information.

Using This Manual

•This Operator’s Manual is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

•The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

•Toordera newOperator’sor PartsManualcontact your

authorized dealer. Manuals can also be downloaded,

free-of-charge from our website at www.landpride.com

orprintedfromtheLandPrideService &SupportCenter

CD-Rom which is at your dealership.

Terminology:

"Right " or "Left" as used in this manual is determined by

facing the direction the machine will operate while in use

unless otherwise stated.

Definitions:

NOTE: A special point of information that the operator

must be aware of before continuing.

IMPORTANT: A special point of information related to

its preceding topic. Land Pride’s intention is that this

information should be read and noted before

continuing.