1-1

Chapter 1

Forklift Safety and Familiarity

Before You Begin (Please Read)

This chapter of the Bendi B40i4 Forklift Operator’s

Manual discusses important safety information regarding

the operation and maintenance of your Forklift.

The safe and efficient operation of a lift truck requires a

skilled and attentive operator.

To develop the skills required:

1. Receive training, pursuant to OSHA 1910.178(1)

dated 12/98, in the proper operation of this forklift.

2. Understand the capabilities and limitations of the lift

truck.

3. Become familiar with the construction of the lift truck

and see that it is maintained in good condition.

4. Read and understand the warnings and operating

procedures in this manual.

The Bendi Series* Model trucks have been designed

for optimum safety of their operators. It is imperative

that all operators follow the safety guidelines listed

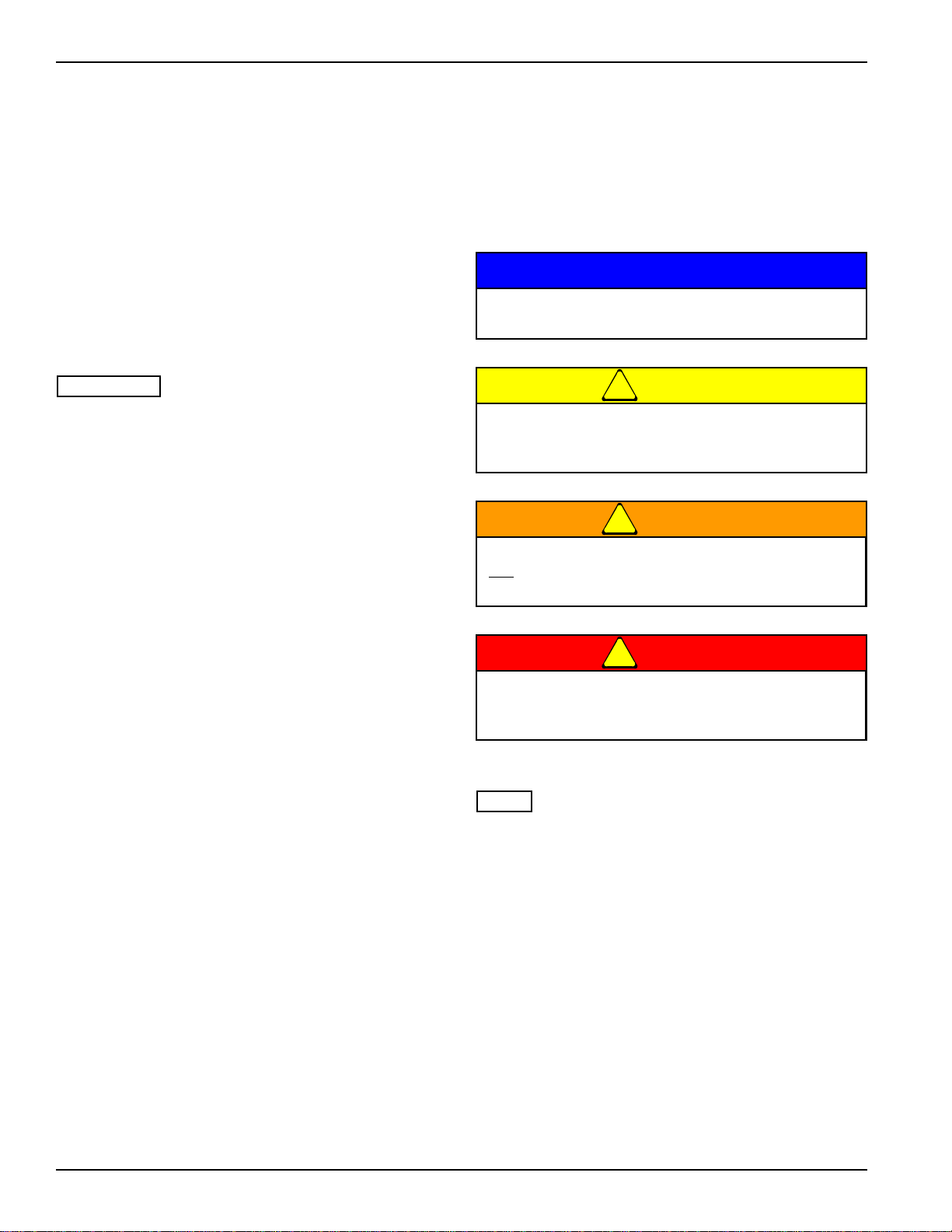

in this section and adhere to all Important, Caution,

Warning and Danger notices found within this

manual.

This chapter on Safety must be carefully read,

understood and adhered to strictly by all operators

and service personnel operating and/or maintaining

the Bendi Series Model lift trucks.

DO NOT use this truck until you have thoroughly read

this manual.

*Landoll and the Bendi Series are trademarks of the

Landoll Corporation. All other brand and product names

are the trademarks of their respective holders.

Landoll Corporation, Bendi Series trucks meet or exceed

ASME B56.1-Part III, Safety/Powered Industrial Trucks.

NO modifications or additions may be made to this

forklift without prior written permission from:

Landoll Corporation

Material Handling Product Group

1900 North Street

Marysville, KS 66508 U.S.A.

Telephone: (785) 562-5381

Fax: (785) 562-4853

Site Supervision

Supervision is an essential element in the safe operation

of powered industrial forklifts. The site supervisor is to

check that the Operator’s Manual is in the seat

compartment on the forklift at all times.

Operators must be trained on the use, maintenance and

safety aspects of the Bendi B40i4 Model trucks, under

the supervision of a trained and experienced operator.

Only those individuals trained to operate and/or service

this truck may do so. Familiarization and driving practice

with a new truck should be arranged in a safe area, away

from other forklifts, obstacles and people. The training

program must be applied to all new operators, regardless

of previous experience. Operator performance must be

evaluated to ensure he/she has the proper skills and

knowledge to operate the truck.

Failure to comply may cause risk of death or

serious injury to yourself and others.

• Do not make modifications or additions to

electrical devices.

• Do not tamper with or disconnect safety

features or modify protective guards, such as

overhead guards or load backrest extensions.

• Do not add or remove structural components.

• Any changes could effect truck capacity or

safe operation of the truck and is a serious

safety violation, that could cause personal

injury or weaken the trucks construction.