5-1

4-5

4-4

4-4

4-3

4-3

4-1

3-5

3-3

Free Spool Clutch Operation

Remote Control (Option) 3-10

....................................................................................................................

........................................................................................

..........................................................................................

.................................................................................................................

.......................................................................................

..................................................................................................................

..............................................................................................................

.......................................................................................

(Option)

......................................................................................

........................................................................................................

........................................................................................................................

....................................................................................................................

.................................................................................................................

..................................................................................................

.................................................................................................

................................................................................................

.................................................................................................

...................................................................................................

..............................................................................

....................................................................................................

................................................................................................

.................................................................................................................

...............................................................................................................

................................................................................................................

...........................................................................................

i

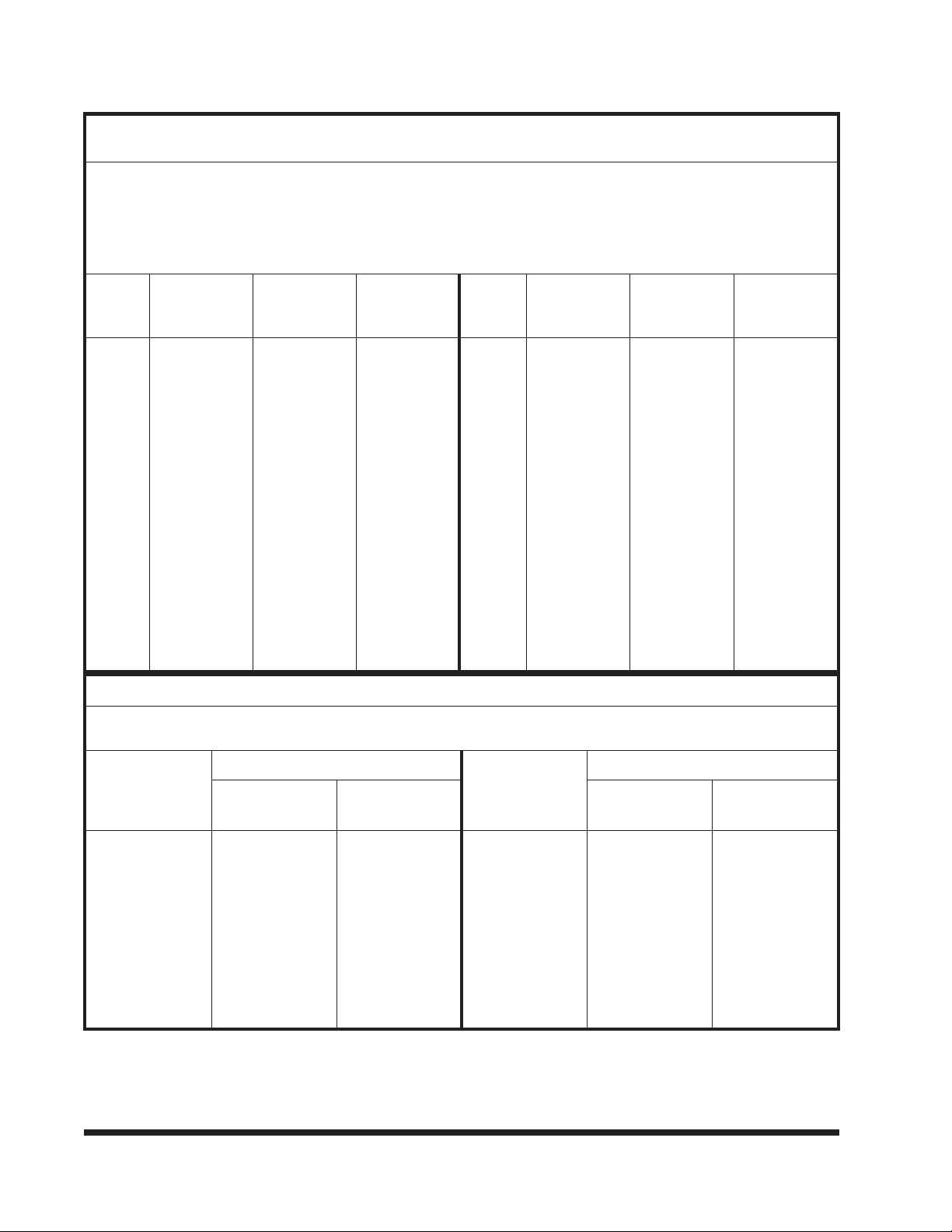

TABLE OF CONTENTS

DESCRIPTION PAGE NO.

INTRODUCTION 1-1

STANDARD SPECIFICATIONS 2-1

OPERATING INSTRUCTIONS 3-1

Bed Tilt Control 3-1

Bed Slide Control 3-4

Winch Controls

Basic Controls 3-5

Special Hitch Control(Option) 3-5

Power Take-off(PTO) 3-5

Bed Loading 3-6

Bed Unloading 3-7

Load Placement 3-7

Securing Loads to Bed 3-7

Hitch Operation(Option) 3-8

Cold Weather Operation 3-11

Hot Weather Operation 3-11

MAINTENANCE and LUBRICATION

Maintenance Schedule

Maintenance Procedures

Frame and Deck

Hydraulic System

Electrical System

TROUBLE SHOOTING GUIDE

Hitch