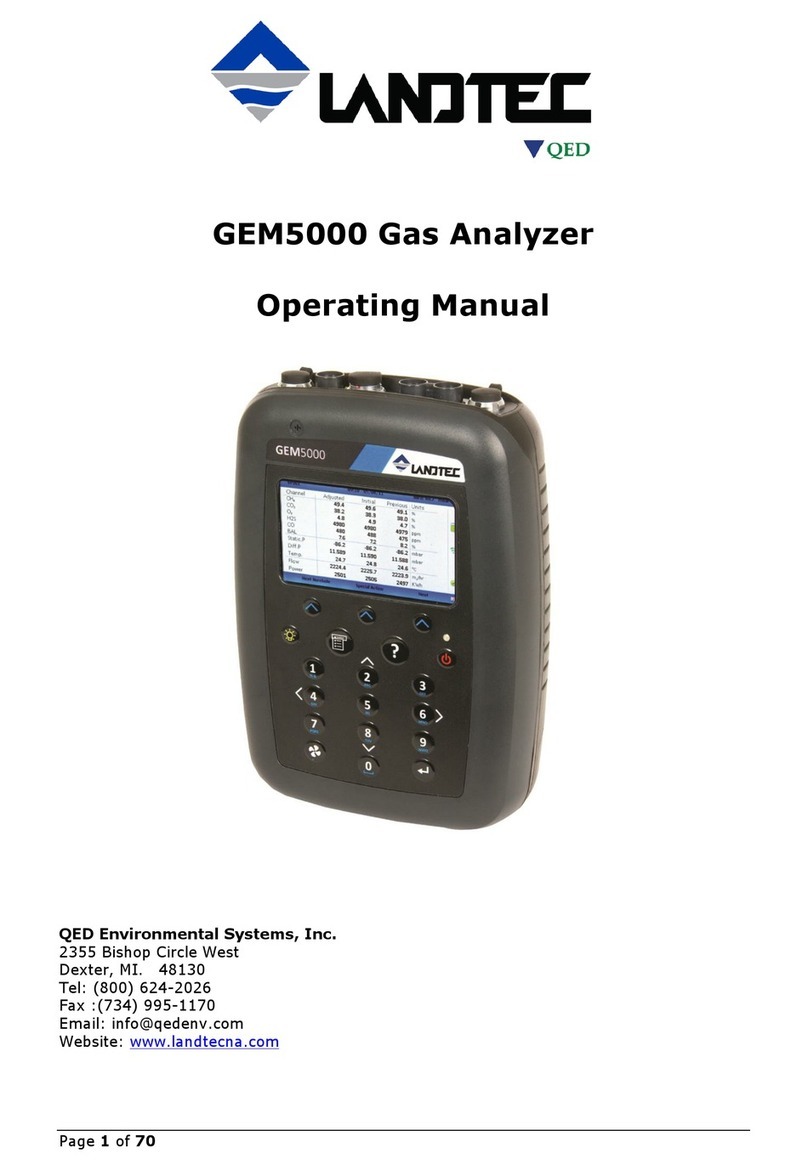

GEM5000 gas analyzer 5K-MNL-GEM5000

1.2 Instructions for safe use

For ATEX and IECEx the 5000 series of gas analyzers are certified to Hazardous

Area Classification

II 2G Ex ib IIA T1 Gb (Ta = +14ºF to +122°F)

It is vital that instructions be followed closely. It is the responsibility of the operator to

determine the protection concept and classification required for a particular application.

(Reference European ATEX Directive 94/9/EC, Annex II, 1.0.6.)

The following instructions apply to equipment covered by certificate numbers SIRA

11ATEX2197X and IECEx Directive SIR 11.0089X:

. The equipment may be used with flammable gases and vapors with apparatus

group IIA and temperature class T1.

. The equipment is only certified for use in ambient temperatures in the range ( -

10ºC to +50ºC) and should not be used outside this range.

. The equipment must not be used in an atmosphere of greater than 21% oxygen.

. Repair of this equipment shall be carried out in accordance with the applicable

code of practice.

. When used in a hazardous area only use (TP-5000 temperature probe (SIRA

11ATEX2197X and IECEx SIR11.0089X).. The analyzer should not be connected to

any other devices in the hazardous area including the 5000-USB cable (connector

A) or GEM5000 BC battery charger (connector B) supplied with the analyzer.

Do not charge, recharge or open in a potentially explosive atmosphere.

In hazardous area only use “TP-5000 Temperature Probe” in Connector B.

Connector C (Uo=10V,lo=5mA,Po=50mW,Ci=0,Li=0,Co=100uF,Lo=1000mH),

Connector B (Uo=5V,lo=6mA,Po=7mW,Ci=0,Li=0,Co=100uF,Lo=1000mH)

MAXIMUM NON-HAZARDOUS SUPPLIES:

Connector A - Um=6V Connector B - Um=10.1V

. If the equipment is likely to come into contact with harmful substances, e.g. acidic

liquids or gases that may attack metals, or solvents that may affect polymeric

materials, then it is the responsibility of the user to take suitable precautions, e.g.

regular checks as part of routine inspections or establishing from the material’s

data sheet that it is resistant to specific chemicals that prevent it from being

adversely affected, thus ensuring that the type of protection is not compromised.

. The relative pressure range is +/-200 in H20 (+/-500 mbar). Note, however, that

the input pressure should not exceed +/-200 in H20 (+/- 500 mbar) relative to

LANDTEC Page 9

5K-MNL-GEM5000 GEM5000 Gas Analyzer