Page A - 2

A

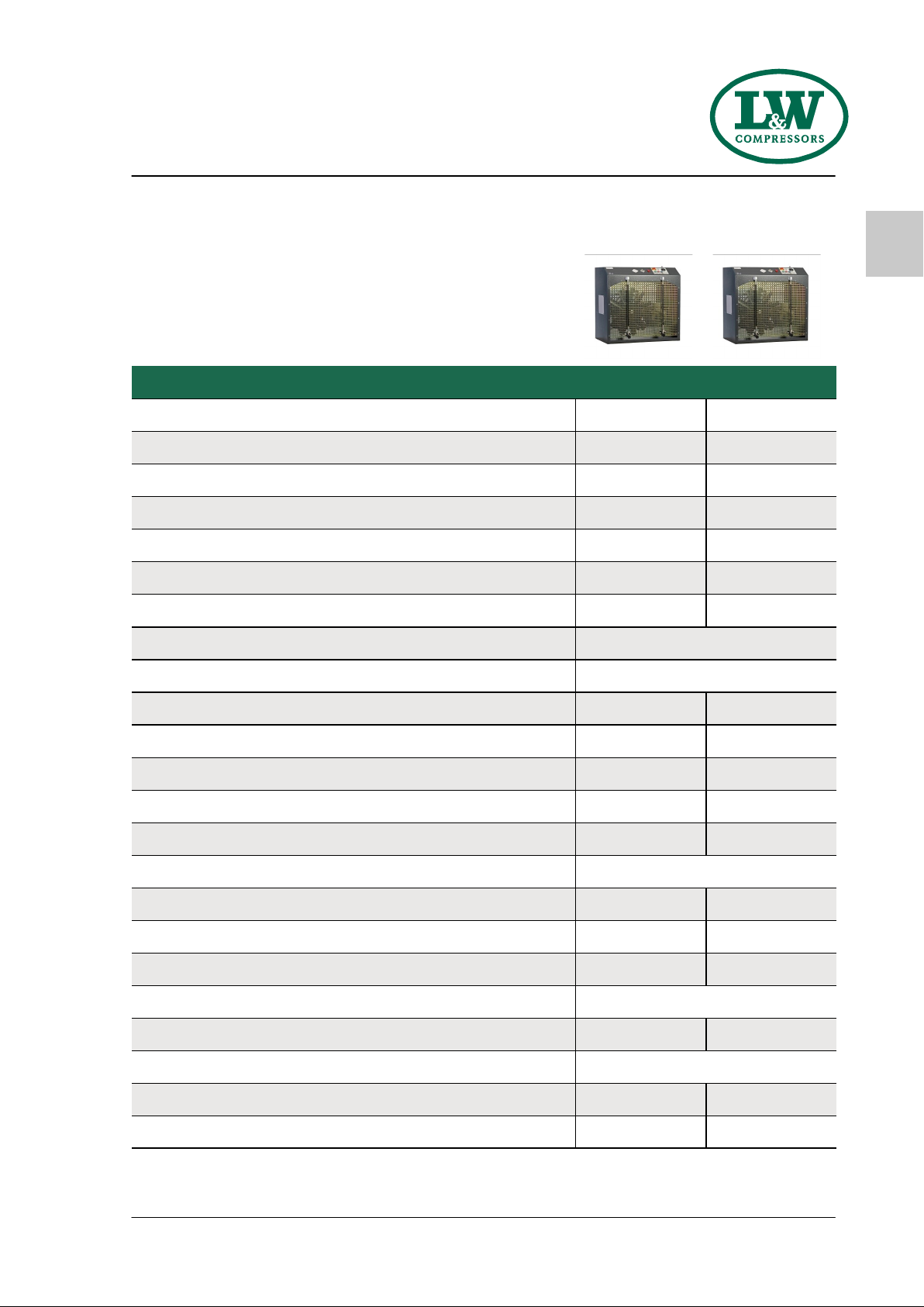

LW SC-300 E / LW SC-350 E

Version: 06.12.2022

T A B L E O F C O N T E N T S

General Information and Technical Data

General Information / Description of Warning Symbols .................................................................... 4

Scope of Delivery .............................................................................................................................. 5

Technical Data .................................................................................................................................. 6

Unit Assembly ................................................................................................................................... 7

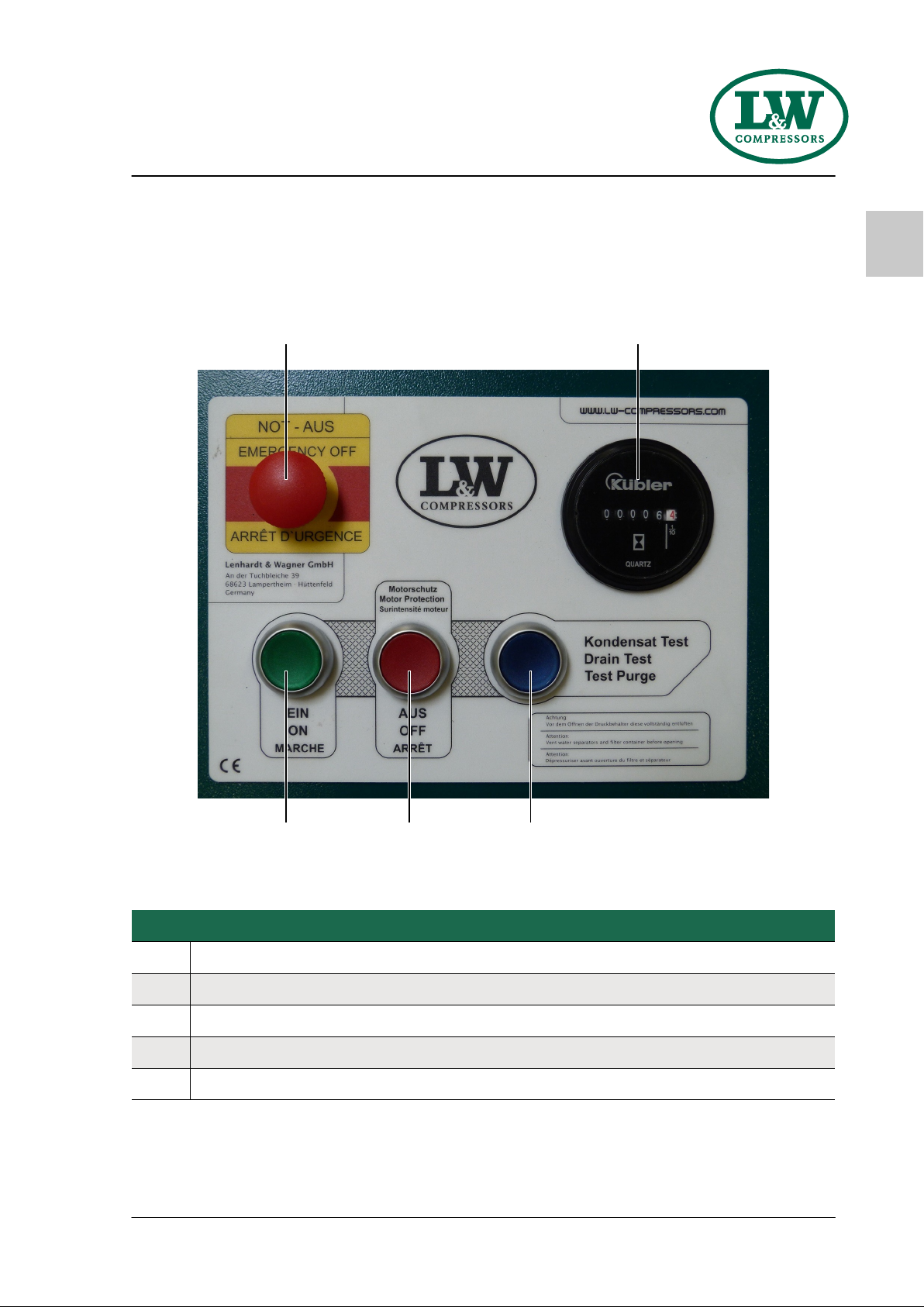

Switchboard ..................................................................................................................................... 8

Flow chart ......................................................................................................................................... 9

Safety Precautions

Intended Use / Operators ................................................................................................................ 11

Safety instructions on the unit ........................................................................................................ 12

General Safety Precautions ............................................................................................................. 13

Unit customised safety notices ........................................................................................................ 14

Maintenance instructions ................................................................................................................ 15

Transportation instructions / Safety regulations .............................................................................. 16

Installation

Installation in closed rooms ............................................................................................................ 18

Dimensions ...................................................................................................................................... 19

Minimum distances ......................................................................................................................... 20

Ventilation ...................................................................................................................................... 21

Electrical Installation ................................................................................................................ 22 - 23

Operation

Important operation instructions .................................................................................................... 25

First commissioning ................................................................................................................. 26 - 28

Daily commissioning ....................................................................................................................... 29

Filling procedure ............................................................................................................................. 30

Switch off the compressor .............................................................................................................. 31

Remedying faults .............................................................................................................. 32 - 36

Maintenance and Service

Service, Repair and Maintenance .................................................................................................... 38

Maintenance Lists / Maintenance Intervals ............................................................................... 39 - 42

Check V-belt tension / Tension V-belt ............................................................................................... 43

Compressor lubrication / Check oil level .......................................................................................... 44

Oil change ...................................................................................................................................... 45

Oil filter maintenance ..................................................................................................................... 46

Final pressure switch ....................................................................................................................... 47