3Follow these instructions

very carefully for safe operation.

Test the whole system with 200 pounds or more of dead load

before attaching your top. Attach a weight or have a heavy

person hang from the hoist frame while you operate the hoist.

Do this a minimum of ten times--very important. This tests

the mechanism, the screw eyes in the wall and ceiling, and lets

you become familiar with the operation of the Cable Pulling

Mechanism. Try this several times, work it hard both up and

down to test everything, especially the ceiling mounting. For

instructions on operating the Cable Puller (1) see the pamphlet

inside the puller's shipping box .

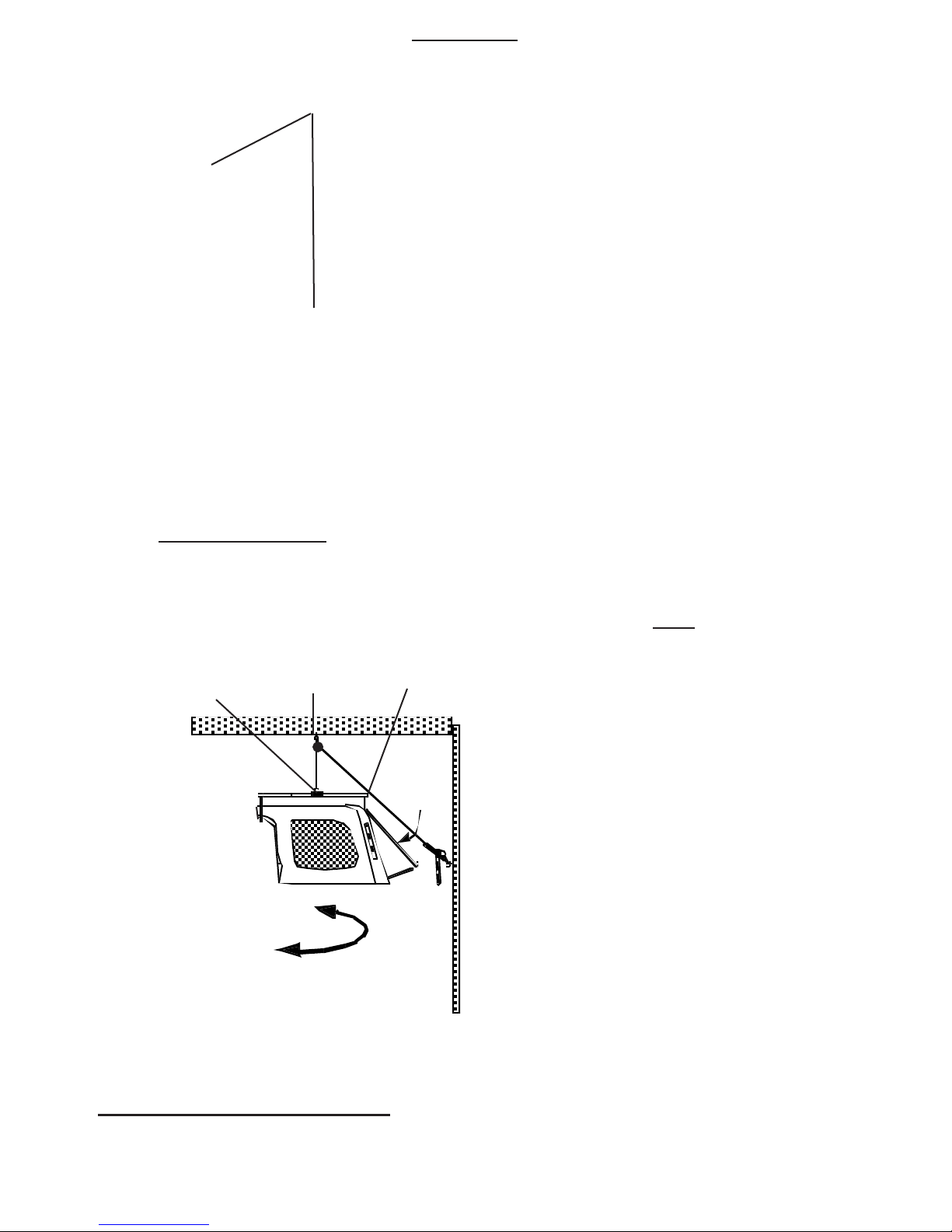

Lifting Your Top

Helpful Hint: Fill an empty one-gallon milk carton about 3/4 full of

water. Slip the handle of the carton through the rear hook on the

empty hoist frame. This will balance your hoist so you can raise

it to the ceiling leveled (without top).

Lift the hoist to the ceiling and back your vehicle directly under

the hoist. (It may pay to mark a line on your garage floor to aid in

aligning your vehicle under the hoist). Open both doors.

Remove all attaching hardware holding your top and the light

plug/washer tube (if any). The hoist is not designed to lift your

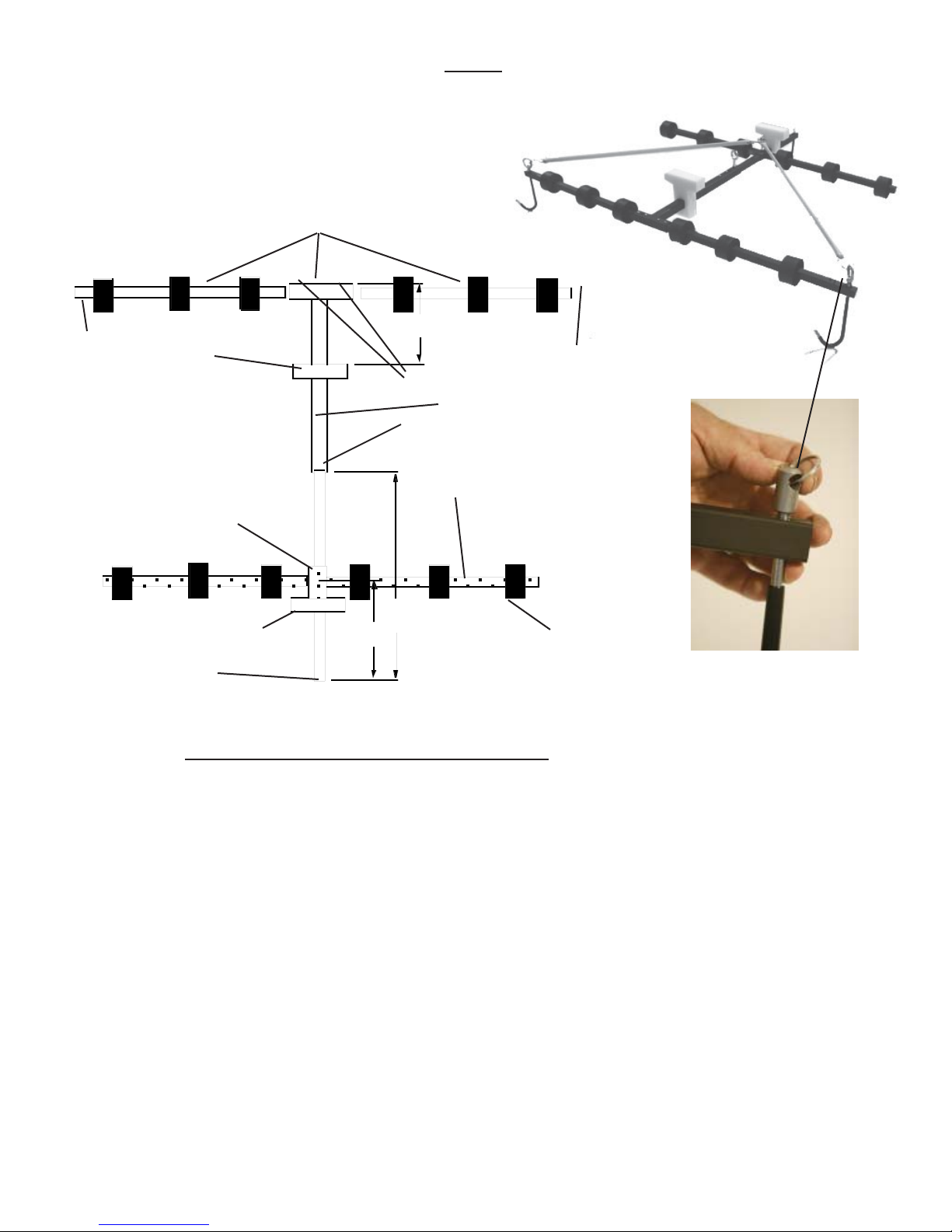

Jeep, just the top. Position the frame as shown in Figure 8.

For all years of Jeep, an "L" rear hook is provided as standard

equipment at the back of the frame. Open the rear window and

slip the hook between the glass and the top. Turn the hook

under and position in the center of top.

Position the J Hooks under the edge at the front of the top (see

Figure 8). Remove and flip the two front sections of the top

and place on the frame of the hoist as shown in Figure 8. Note

that the sections are upside down with the "S" shape to the front.

Slide the top so that in back edge is nestled against the foam "T"

supports. Install the Stretch cords (15) as shown in Figure 8.

!!Caution!: Wear eye protection when using cords.

Crimping the back hook on the Stretch Cords will make securing

the top sections easier. Stretch the cords diagonally across the

top sections to the Eye Nuts (14) as shown in Figure 8. This

secures the top sections to the hoist. Having a friend help you

with the next operation will be helpful!!

Make sure the hoist is set to lift. See instructions in the Cable

Puller Box for lifting and lowering settings for the wire cable

puller. Lift your top off slowly a few inches. Use one hand on the

side to balance the top until it clears the vehicle body. Make

sure the top balances so that it remains fairly level when in the

stored position (Hanging slightly lower at the back will aid in

installation). To change the balance, move the Balance Slide,

see Figure 5 (either to the front of the jeep to lower the rear or to

the rear of the jeep to lower the front). Make sure you replace

the top back on the vehicle before moving the slide. When

the balance point is found, tighten the eyebolt until it presses

hard into the rear support bar, then tighten the safety lock nut to

additionally secure the eyebolt. Lift your top slowly a few inches

and recheck everything.

!CAUTION!: When lifting, keep fingers and arms away from

the underside of your top. Remember that all lift mecha-

nisms can fail without warning! Keep children and pets away

from the mechanism and out from under the top when stored

on the lift.

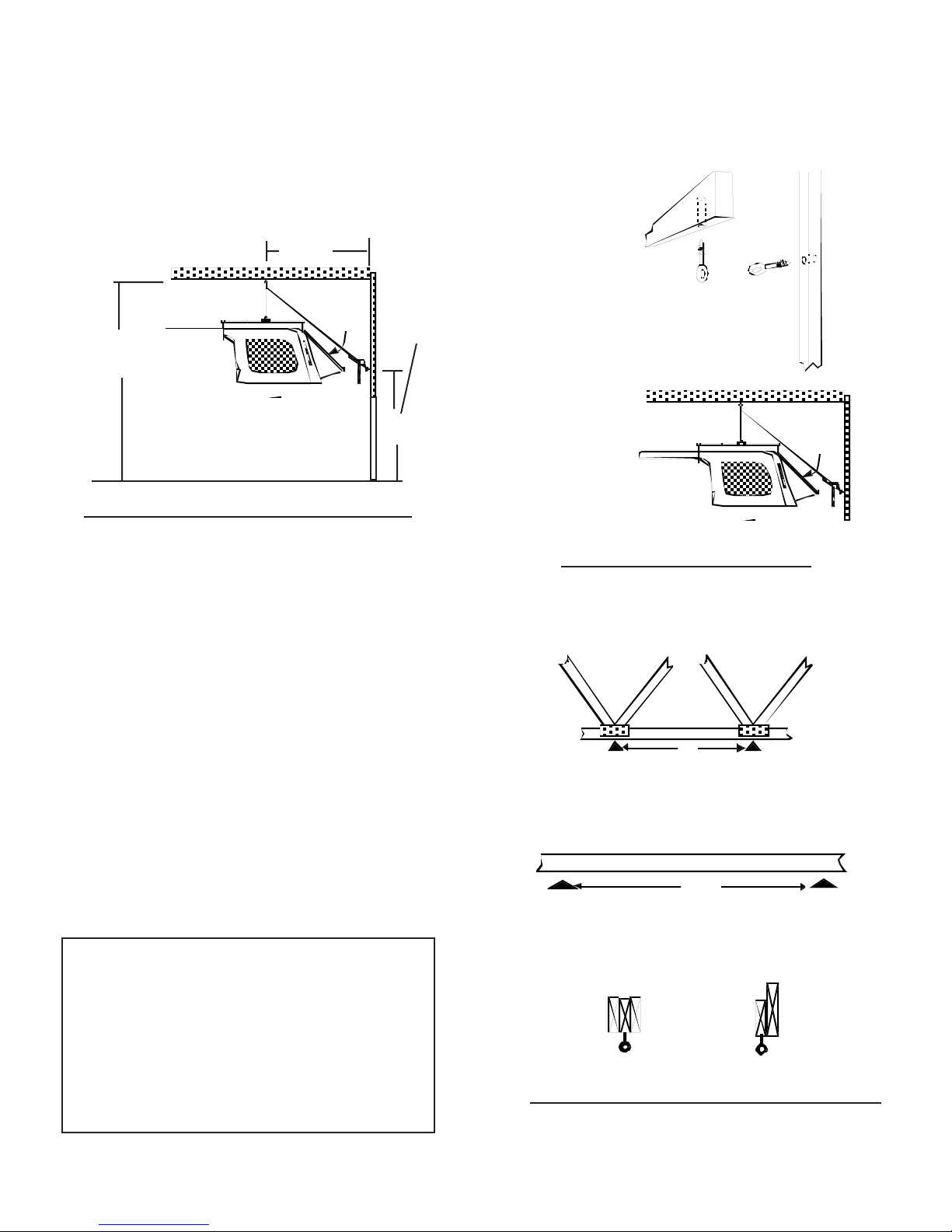

Figure 6 Foam "T"

Installation

Note, that the foam is shaped slightly differently in the

profile below. The highest side of the "T" goes on the

passengerside asshowbelow.

Front

Using the Hoist-a-Top

Figure 7, Mounting Connections

After lifting your top, you

findthatthereis not enough

room for the rear window to

clear the hoist cable, rotate

the top 90 degrees and

leave the window up or

close partiallyand secure

with a cord. Optional tape

or cord holds window

closed(onlyclose half way

or you will break the

window). Exercise care in

closing window with the

hook in place to prevent

damage to window. We

don'trecommendclosing

the window! !Caution!

Keep the cable and other

objects clear of the window

glass or it may break.

RearL-Hookslips

betweentheglass and

the top

Move the slide to

adjust the balance of

the top if required.

You may rotate the top

after lifting to facilitate

ease of storage

Hookthepulley

onthepuller

cableintothe

ceilingeyebolt

Closehalf

way is

optional

4-Door JK Sheet 4