- 3 -

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.com

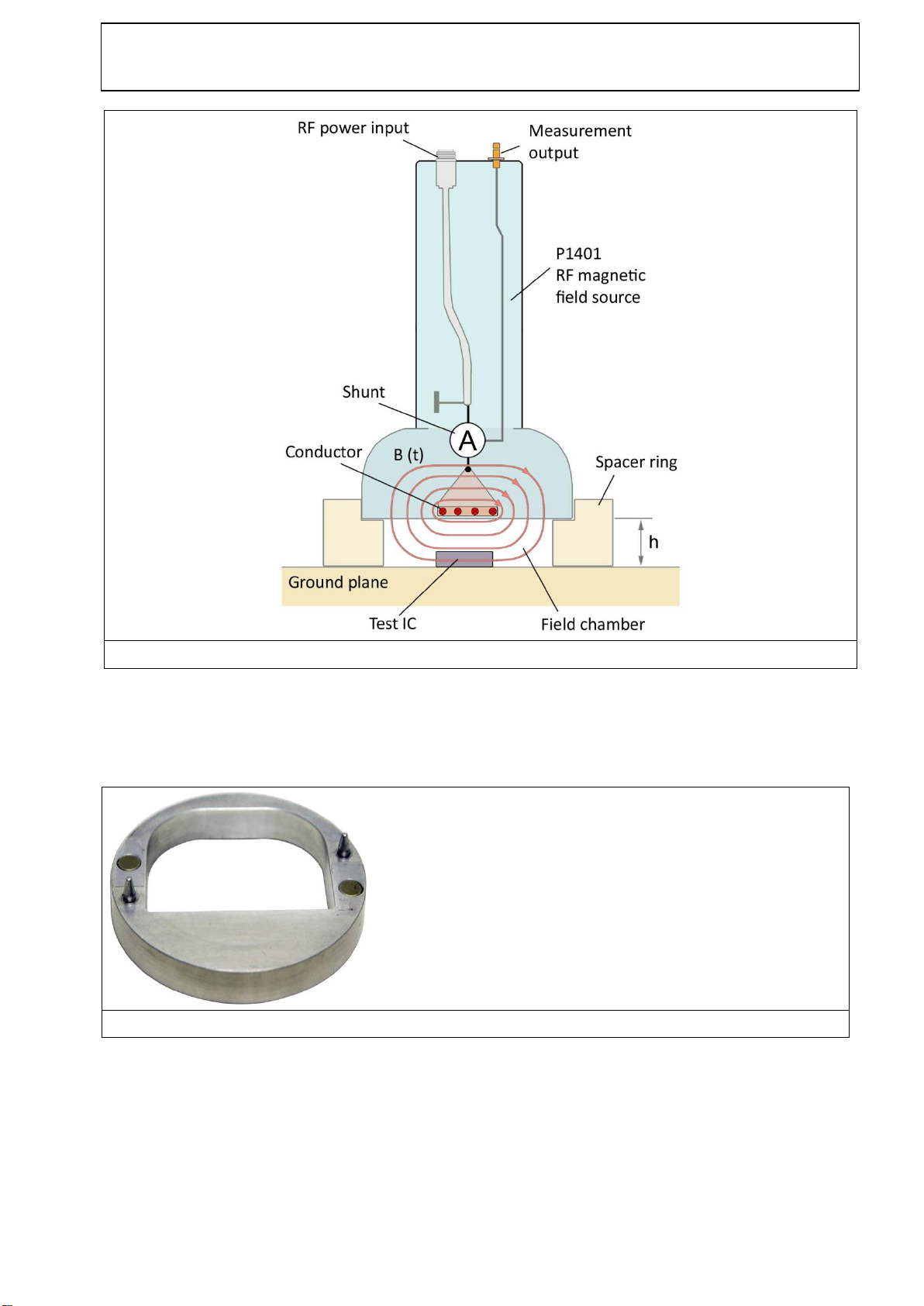

P1401/P1501 and P1402/P1502 set

1 Safety instructions

Read and follow the operating instructions carefully and keep them in a safe place for later

consultation. The devices may only be used by personnel who are qualified in the field of

electromagnetic compatibility (EMC) and who are eligible to carry out this work.

When using a product from Langer EMV Technik GmbH, please observe the following safety

instructions to protect yourself from electric shocks or the risk of injuries and to protect the devices

used and the test IC from destruction.

Use a power amplifier that is stable under open-circuit conditions and short-circuit proof.

Observe the operating and safety instructions for all devices used in the set-up.

Never use any damaged or defective devices.

Carry out a visual check before using a measurement set-up with a Langer EMV-

Technik GmbH product. Replace any damaged connecting cables before starting

the product.

Never leave a product from Langer EMV-Technik GmbH unattended whilst this is

in operation.

The Langer EMV-Technik GmbH product may only be used for its intended

purpose. Any other use is forbidden.

People with a pace-maker are not allowed to work with these devices.

The test set-up should always be operated via a filtered power supply.

Attention! Functional interference emissions (near fields and far fields) may occur when the

field sources from the P1401/P1501 set or P1402/P1502 set are operated. The user is

responsible for taking appropriate measures to protect all electronic devices used in the

course of the tests. In particular, the user is responsible for protecting the measuring

devices used for the test set-up and all other electronic devices outside the test bench

against interference emissions so that their intended function is not impaired. This can be

achieved by:

- observing an appropriate safety distance

- use of shielded rooms or enclosures (e.g. shielded tents)

A disturbance field is generated in the field chamber of the field source when operating the

test bench. Make sure that the field chamber is not opened under any circumstances during

the test for safety reasons (hazard due to RF). The field source may only be operated with

the field chamber closed and in accordance with the measurement set-up. The test bench

has to be operated in a shielded room or enclosure.

We cannot assume any liability for damage due to improper use.

The disturbances that are injected into the modules can destroy the test IC (latch-up) if their

intensity is too high. Protect the device under test by:

- connecting a protective resistor in the IC's incoming power supply

- increasing the disturbance gradually and stopping when a functional fault occurs

- interrupting the power supply to the test IC in the event of a latch-up.