2

DE-01728 Bannewitz

mail@langer-emv.de

www.langer-emv.com

Content:............................................................................................................. Page

1. Declaration of Conformity...........................................................................................3

2. General Information.....................................................................................................4

2.1. Storing the User Manual..........................................................................................................4

2.2. Reading and Understanding the Manual.................................................................................4

2.3. Local Safety and Accident Prevention Regulations ................................................................4

2.4. Images......................................................................................................................................4

2.5. Limitations of Liability...............................................................................................................4

2.6. Errors and Omissions ..............................................................................................................4

2.7. Copyright..................................................................................................................................4

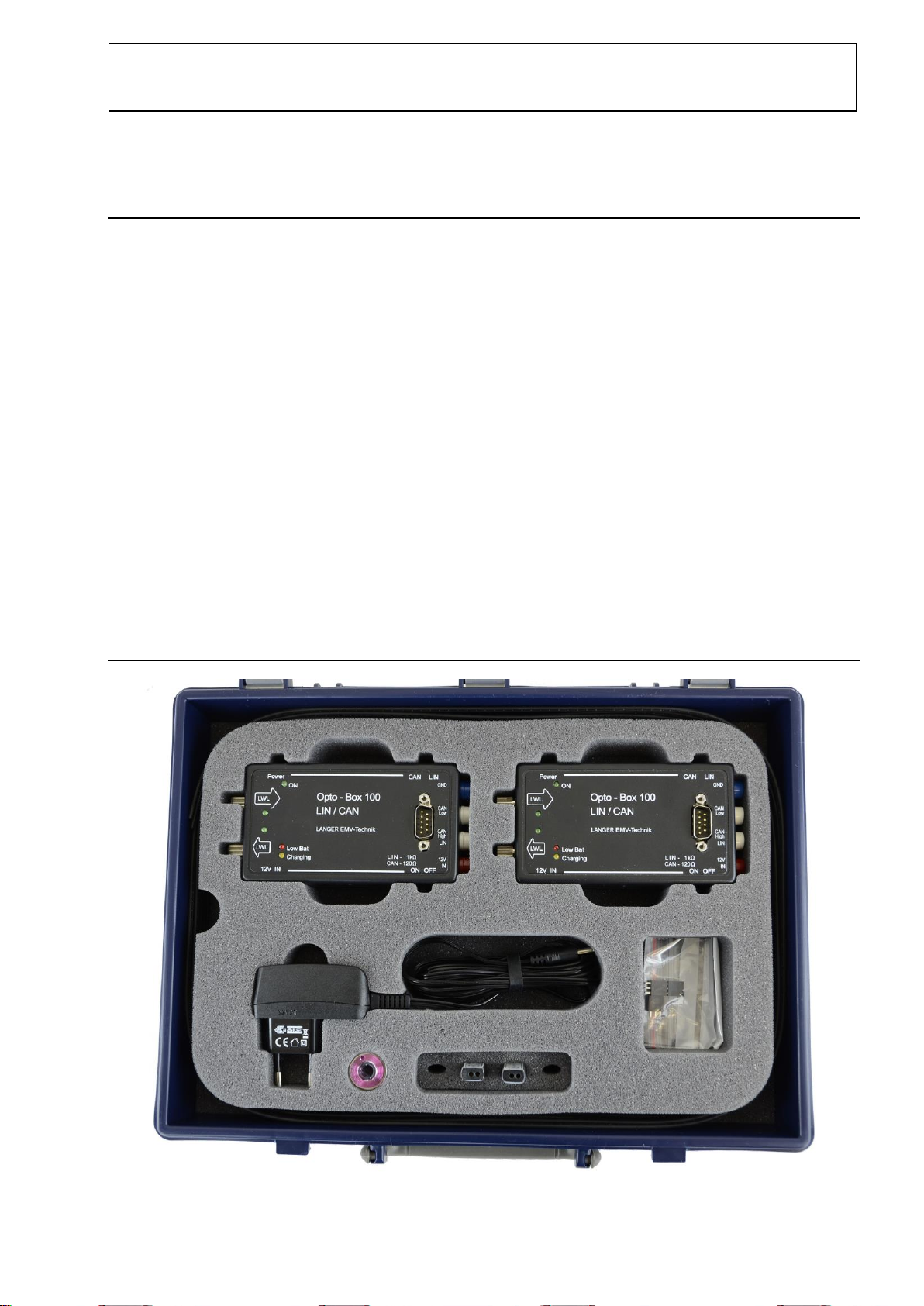

3. Scope of Delivery.........................................................................................................5

4. Technical Parameters..................................................................................................6

4.1. OB 100 - Opto-Box 100 ...........................................................................................................6

4.2. CAN 100 - Optical Fiber Probe................................................................................................6

4.3. LIN 100 - Optical Fiber Probe..................................................................................................6

5. Safety Instructions.......................................................................................................7

6. Information on Recycling and Disposal .....................................................................8

7. Application ...................................................................................................................9

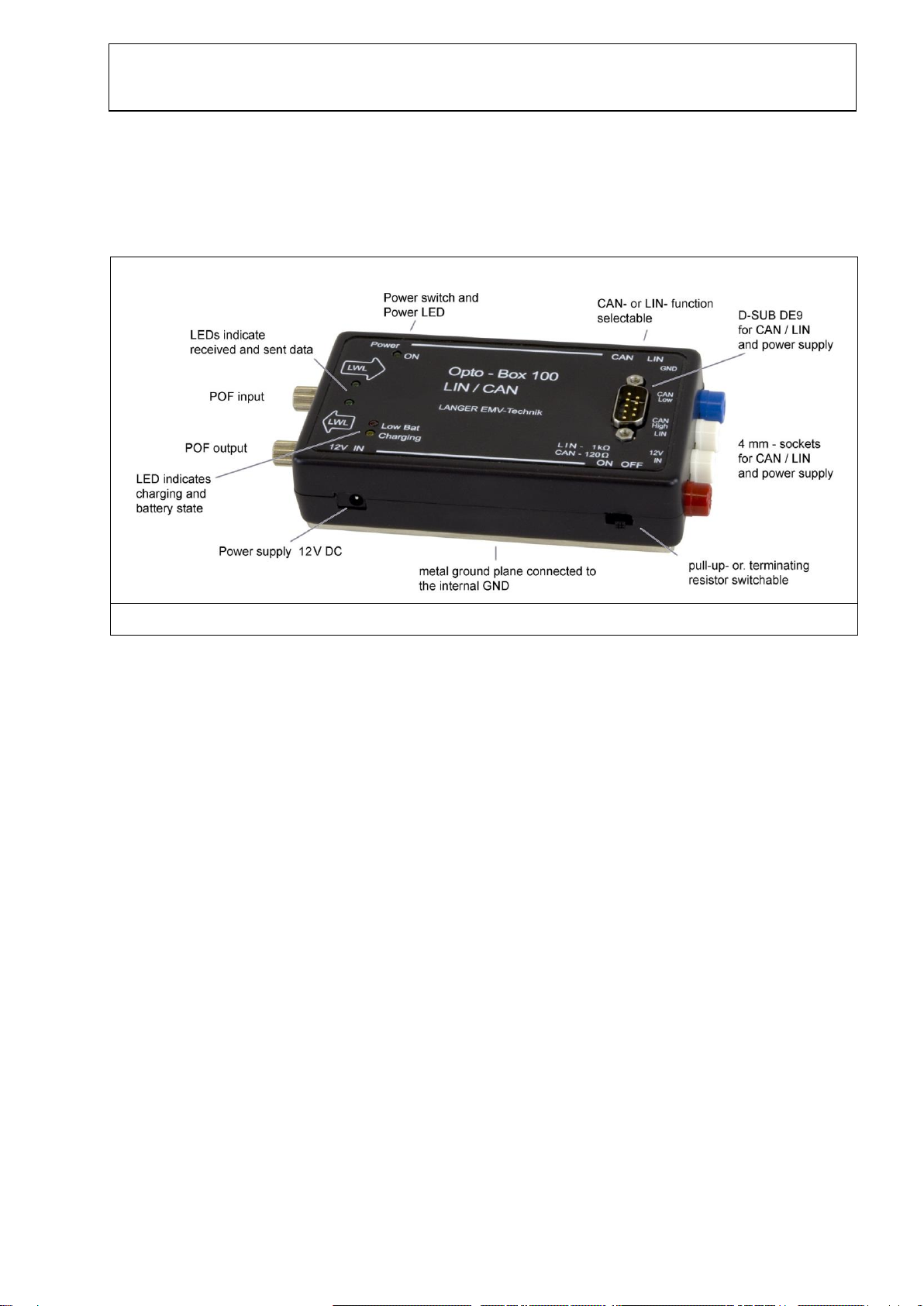

8. Design of Opto-Box 100.............................................................................................10

8.1. Mechanical Design.................................................................................................................10

8.2. GND Connection....................................................................................................................10

8.3. Voltage Supply.......................................................................................................................11

8.4. Signal Transmission –Electrical Connection........................................................................12

8.5. Signal Transmission –Optical Connection............................................................................13

9. Use of Opto-Box 100..................................................................................................14

9.1. Measurements according to Standards.................................................................................14

9.2. Measurements during Development......................................................................................15

10. CAN 100 / LIN 100 Sensors...................................................................................16

10.1.Mechanical Design.................................................................................................................16

10.2.Optical Connection.................................................................................................................16

10.3.Electrical Connection.............................................................................................................17

11. Warranty.................................................................................................................18

12. Customer Service..................................................................................................19