Novanta Celera Motion Optira Series User manual

MicroE Optira Installation Manual

Celera Motion

IM

-1001 | REV181211 Page i ©2018 Celera Motion

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page i ©2018 Celera Motion

1.0 Table of Contents

2.0 Introduction.......................................................................................................................................1

2.1 Overview .............................................................................................................................1

2.2 Precautions .........................................................................................................................1

2.3 Laser Safety Information .....................................................................................................1

2.4 Standards Compliance ........................................................................................................2

2.5 Related Documentation.......................................................................................................2

2.6 Trademarks .........................................................................................................................2

2.7 Special Conventions Used ..................................................................................................2

3.0 Before Installation.............................................................................................................................3

3.1 Power Recommendations ...................................................................................................3

3.2 Installation Considerations ..................................................................................................3

3.3 Items Required for Installation ............................................................................................3

3.4 Sensor Installation Flowchart ..............................................................................................4

4.0 System Overview .............................................................................................................................5

4.1 Top Mounting ......................................................................................................................5

4.2 Board-to-Board Mounting....................................................................................................6

4.3 Optional Development Kit ...................................................................................................7

4.4 Optional Connector and Calibration Board .........................................................................7

5.0 Design Mounting ..............................................................................................................................8

6.0 Sensor Installation............................................................................................................................8

6.1 Install Sensor.......................................................................................................................8

6.1.1 Sensor Mounting Orientation and Tolerances .......................................................9

6.1.2Top Mounting .........................................................................................................9

6.1.3 PCB Mounting ......................................................................................................11

6.1.4 Sensor Head Alignment .......................................................................................11

6.1.5 LSB Index Calibration ..........................................................................................12

6.2 Install Optional Connector and Calibration Board.............................................................14

7.0 Appendix ........................................................................................................................................15

7.1 Specifications ....................................................................................................................15

7.2 Power-Up Timing...............................................................................................................16

7.3 Sensor Connectors Pinouts ..............................................................................................16

7.4 Recommended Signal Termination...................................................................................17

7.5 Board-to-Board Header Wiring Examples.........................................................................18

7.6 Connector and Calibration Board Connector Pinouts .......................................................20

7.7 Customer Interface............................................................................................................21

7.8RS-422 Compatibility.........................................................................................................21

7.9 Troubleshooting.................................................................................................................21

8.0 Order Guide....................................................................................................................................22

9.0 Introduction to Scale Mounting.......................................................................................................23

9.1 Overview ...........................................................................................................................23

10.0 Rotary Scales .................................................................................................................................24

11.0 Tape Scale Installation ...................................................................................................................24

11.1 Before Installation..............................................................................................................24

11.1.1 Items Required for Tape Scale Installation ..........................................................24

11.1.2 Pre-Installation Information and Precautions .......................................................24

11.1.3 Flowchart for Tape Scale Installation ...................................................................26

11.1.4 Design Guide........................................................................................................27

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page ii ©2018 Celera Motion

11.1.5 Prepare Mounting Surface ...................................................................................28

11.2 Cutting Tape Scales ..........................................................................................................29

11.3 Install the Tape Scale........................................................................................................30

11.3.1 Install Tape Scale Manually .................................................................................30

11.3.2 Install Tape Scale Using the Applicator Tool .......................................................34

12.0 Linear Glass Scales Installation .....................................................................................................43

12.1 Before Installation..............................................................................................................43

12.1.1 Items Required for Glass Scale Installation .........................................................43

12.1.2 Flowchart for Glass Scale Installation ..................................................................43

12.2 Benching Linear Glass Scales ..........................................................................................44

12.3 Prepare Mounting Surface ................................................................................................44

12.4 Install Linear Glass Scales ................................................................................................44

13.0 Final Cleaning, Inspection, and Cure Time....................................................................................45

13.1 Reworking to Correct Mistakes .........................................................................................45

13.2 Cleaning Scales ................................................................................................................45

14.0 Contacting Celera Motion...............................................................................................................45

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 1 ©2018 Celera Motion

2.0 Introduction

2.1 Overview

The instructions in this manual apply to the following Optira Series Encoders models:

•Model PIA Standard 5 V

•Model PIB Standard 3.3 V

2.2 Precautions

1. Follow standard ESD precautions. Turn power to off before connecting sensor.

2. Do not touch electrical pins without static protection such as a grounded wrist

strap.

2.3 Laser Safety Information

This product is sold solely for use as a component (or replacement) in an electronic product;

therefore, it is not required to, and does not comply with U.S. FDA 21 CFR 1040.10 and 1040.11

which pertain to complete laser products. The manufacturer of the complete system-level

electronic product is responsible for complying with 21 CFR.

MicroE Systems encoders contain an infrared laser diode or diodes. Emitted invisible laser

radiation levels have been measured to be within the CDRH Class 1 range, which is not

considered hazardous; however, to minimize exposure to the diverging beam, install the encoder

sensor in its operational configuration in close proximity to the encoder scale before

applying power.

•Invisible laser radiation; wavelength: 850 nm.

•Maximum power of 4.8 mW CW for Optira.

•Caution: The use of optical instruments with this product will increase eye hazard. Do

not view directly with optical instruments (microscopes, eye loupes, or magnifiers).

•All maintenance procedures such as cleaning must be performed with the MicroE

encoder turned off.

•Do not insert any reflective surface into the beam path when the encoder is powered.

•Do not attempt to service the MicroE encoder.

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 2 ©2018 Celera Motion

2.4 Standards Compliance

Optira Series Encoders are RoHS, REACH, and CE compliant.

2.5 Related Documentation

•Optira Series Encoders Data Sheet

•Optira Series Encoders Interface Drawings

2.6 Trademarks

Optira trademark of Novanta Inc. d/b/a Celera Motion.

2.7 Special Conventions Used

The following symbols may be used in this document.

Symbol

Description

Warning or caution: potential damage to parts.

Instructions show correct method.

Instructions show example of incorrect method.

See Section 2.2 Single click with the mouse on these highlighted references

to jump to specified places in instructions.

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 3 ©2018 Celera Motion

3.0 Before Installation

Review the items in this section prior to installing the encoder.

3.1 Power Recommendations

Optira Series Encoders can be ordered with either 5 VDC or 3.3 VDC power supplies:

Power

Supply

Minimum

Input

Voltage

Maximum

Input

Voltage

Maximum

Current Draw

(Digital)

Maximum

Current Draw

(Analog)

Maximum

Current Draw

(No Load)

5.0 VDC

4.75 VDC

5.25 VDC

130 mA

100 mA

75 mA

3.3 VDC

3.13 VDC

3.46 VDC

130 mA

100 mA

75 mA

When designing circuits and extension cables to use Optira encoders, be sure to account for

voltage loss over distance and tolerances from the nominal supply voltage so that at least the

minimum continuous voltage is available to the Optira encoder under all operating conditions.

3.2 Installation Considerations

The Optira encoder is a precision electronic instrument. It has been designed to function in a wide

range of applications and environments. To take full advantage of the Optira design, allow easy

access to the sensor for service and/or replacement.

For optimal performance and reliability:

•DO follow standard ESD precautions while handling the sensor.

•DO allow proper clearance for sensor head alignment.

•DO follow setup and calibration instructions for the encoder system.

•DO, where possible, install the scales in an inverted or vertical position to minimize

accumulation of dust.

•DO NOT store sensors in an uncontrolled environment.

•DO NOT electrically overstress the sensor (power supply ripple/noise).

•DO NOT intentionally “hot swap” the sensor if the device is energized.

•DO NOT use in high contamination applications (dust, oil, excessive humidity, or other

airborne contaminants).

3.3 Items Required for Installation

In addition to the items identified in Section 3.0 System Overview,you will need the following

items available for installation:

Item

Z-Height shim1(0.020")

Screwdriver

Finger Cots or talc-free gloves

Acetone or isopropyl alcohol

Lint-free cotton cloths or wipes

Epoxy, non-conductive2

Stick and disposable surface for stirring epoxy2

Notes:

1. Part of optional Development Kit; not required if using a benching edge for installation.

2. Not required for all installations.

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 4 ©2018 Celera Motion

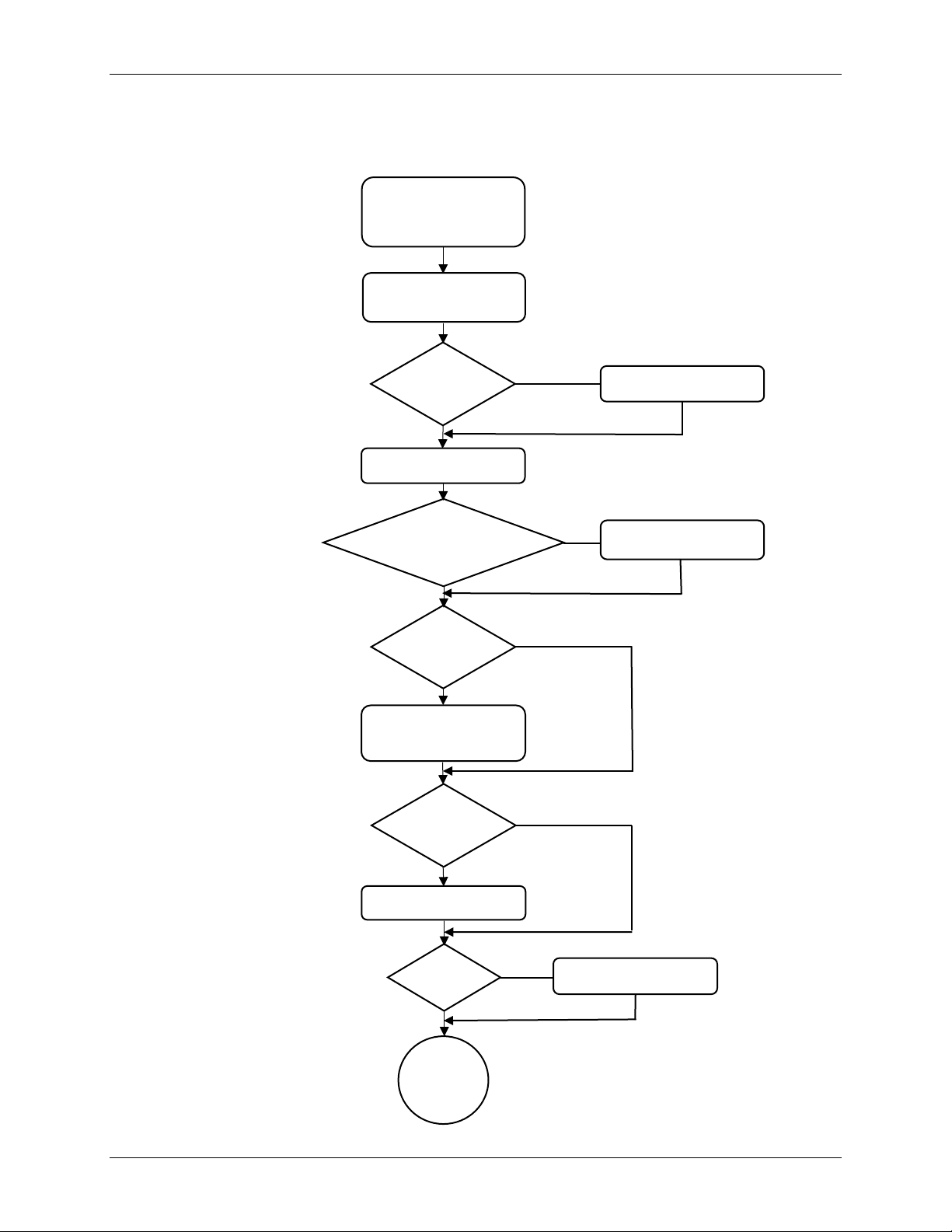

3.4 Sensor Installation Flowchart

The following flowchart shows the main steps in encoder installation, alignment, and calibration.

Design Mounting

Is Z-Height

adjustable?

Align Sensor

No

Yes

Set Z-Height

using shim

Benching

Edge?

Install

Complete

LSB?

Install Scale

Calibrate

Install Sensor

Yes

No

Yes

No

Optional Connection

and Calibration board? Install board

Yes

No

Install Flex

Cable? Attach Flex Cable

No

Yes

Section 4.0

Section 5.1.4

Section 5.0

Section 5.1.5

Section 5.0

Section 5.1

Section 5.2

Section 5.1.2

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 5 ©2018 Celera Motion

4.0 System Overview

This section identifies parts for the Optira sensor installation. Use the information in this section to

design the mounting scheme for the sensor and the optional connector and calibration board.

Refer to the Optira Series Encoders Interface Drawings for details. Alignment not required when

benching sensor.

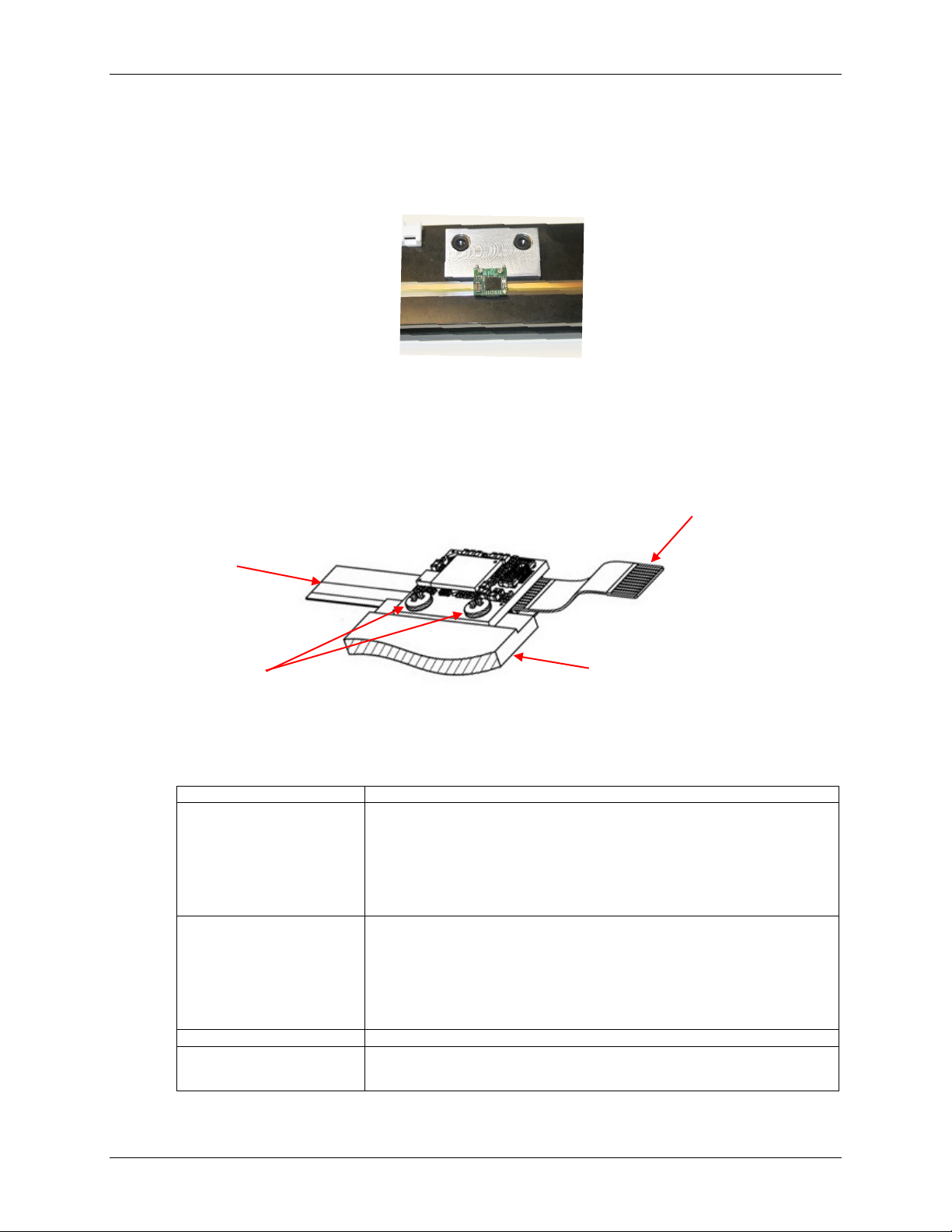

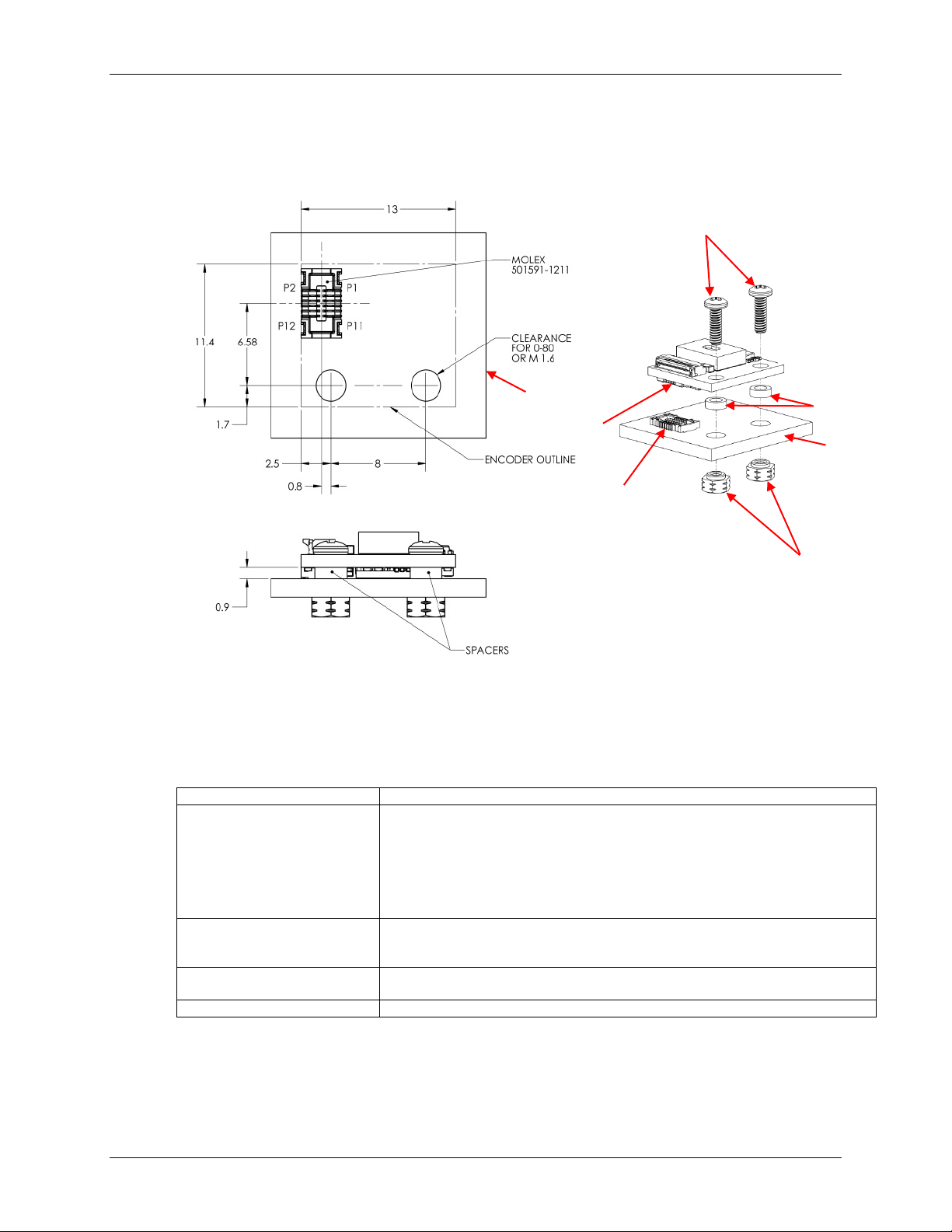

4.1 Top Mounting

This section contains information needed for installing the sensor in a top mount configuration.

The sensor can be mounted directly to customer’s bracket or equivalent surface using two

mounting screws.

Recommended Customer Required Parts

The following parts or their equivalents are recommended for the mechanical mounting of the

Optira sensor.

Item

Description

Mounting Screws (2)

M1.6 or 0-80 screws. Philips head screws are recommended. Do not use

slotted-head screws which can allow the screwdriver to slip and damage

components. Tighten screws per torque specification: 0.34Nm (3 inch-

lbs.) maximum.

Caution: Be careful tightening these screws to avoid damaging nearby

components.

FFC Cable

Flexible Flat Cable (FFC): 0.5 mm, Type 1, 10 P. Maximum length of 5 m.

J1 ZIF Connector is Hirose®FH33J-10S-0.5SH(10).

If long flex cables are needed, contact Selmark Associates for Parlex®

cables or contact another equivalent manufacturer.

Tip: For high mechanical stress environments, secure FFC to ZIF

connector using non-conductive epoxy.

ZIF Connector

Various FFC Connectors, Surface Mount, ZIF, 10 pins, .5 mm pitch.

Z-Height Shim Spacer

Shim for setting gap between sensor riser and top of installed scale. Not

needed for most installs. (Part of optional Development Kit)

Note: For scales, see Optira Series Encoders Tape and

Glass Scales Installation Manual.

Detachable FFC Cable

Mounting Screws

Tape Scale

Customer Provided Bracket

Sensor

Example of installed sensor

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 6 ©2018 Celera Motion

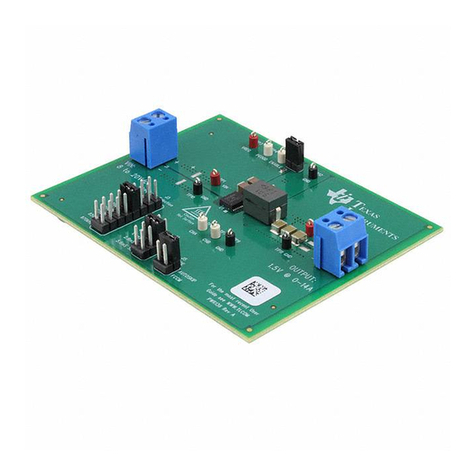

4.2 Board-to-Board Mounting

This section contains information needed for installing the Optira sensor to the customer's PCB.

Recommended Customer Required Parts

The following parts or their equivalents are recommended for the board-to-board mounting of the

Optira sensor.

Item

Description

Mounting Screws (2)

M1.6 or 0-80 screws. Philips head screws are recommended. Do not use

slotted-head screws which can cause the screwdriver to slip and damage

components. Tighten screws per torque specification: 0.34 Nm (3 inch-lbs.)

maximum.

Caution: Be careful tightening these screws to avoid damaging nearby

components.

PCB Mount Connector1

Molex

®

part number 501591-1211: 0.40 mm (.016") pitch board-to-board

vertical mating receptacle. Mates to JP1 board-to-board connector (Molex

part number 501594-1211) on sensor.

Spacers (2)

Diameter cannot exceed keep-out area of 3.17 mm (see sensor dimensions

on Optira Interface Drawing). Height is .9 mm.

Surface Mount Fasteners (2)

MicroPEM®Fasteners, Type is SMTSO .060-80 (#0-80) or equivalent.

Note1: Header Mating: The header mating connector has a limited durability of 20 mating cycles

maximum.

Customer Bracket

Molex 501591-1211

Molex 501594-1211

Screws

Surface Mount Fasteners

Sensor

Bottom View

Spacers

Customer

Bracket

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 7 ©2018 Celera Motion

4.3 Optional Development Kit

The following are the components of the optional Development Kit model PI-DK:

Part

Description

Connector and

Calibration Board

Interface board located between the Optira sensor and the customer’s controller:

•Provides feedback of sensor operation to customer electronics

•Provides control for calibration and alignment

•Size: 0.591" x 0.886"

•No signal processing

200mm FFC Cable

Flat flexible cable (FFC) that connects sensor to optional interface board or

directly to customer electronics:

•Digikey 732-3556-ND

•Wurth Electronics®part number 687610200002 (0.5 mm, Type 1, 10P,

200 mm)

3m Controller Cable

Custom Development Kit Cable with JST®Connector and 15-Pin D-Sub to

connect between Connector and Calibration Board and customer’s electronics.

Z-Height Shim Spacer

Shim for setting gap between sensor riser and top of installed scale.

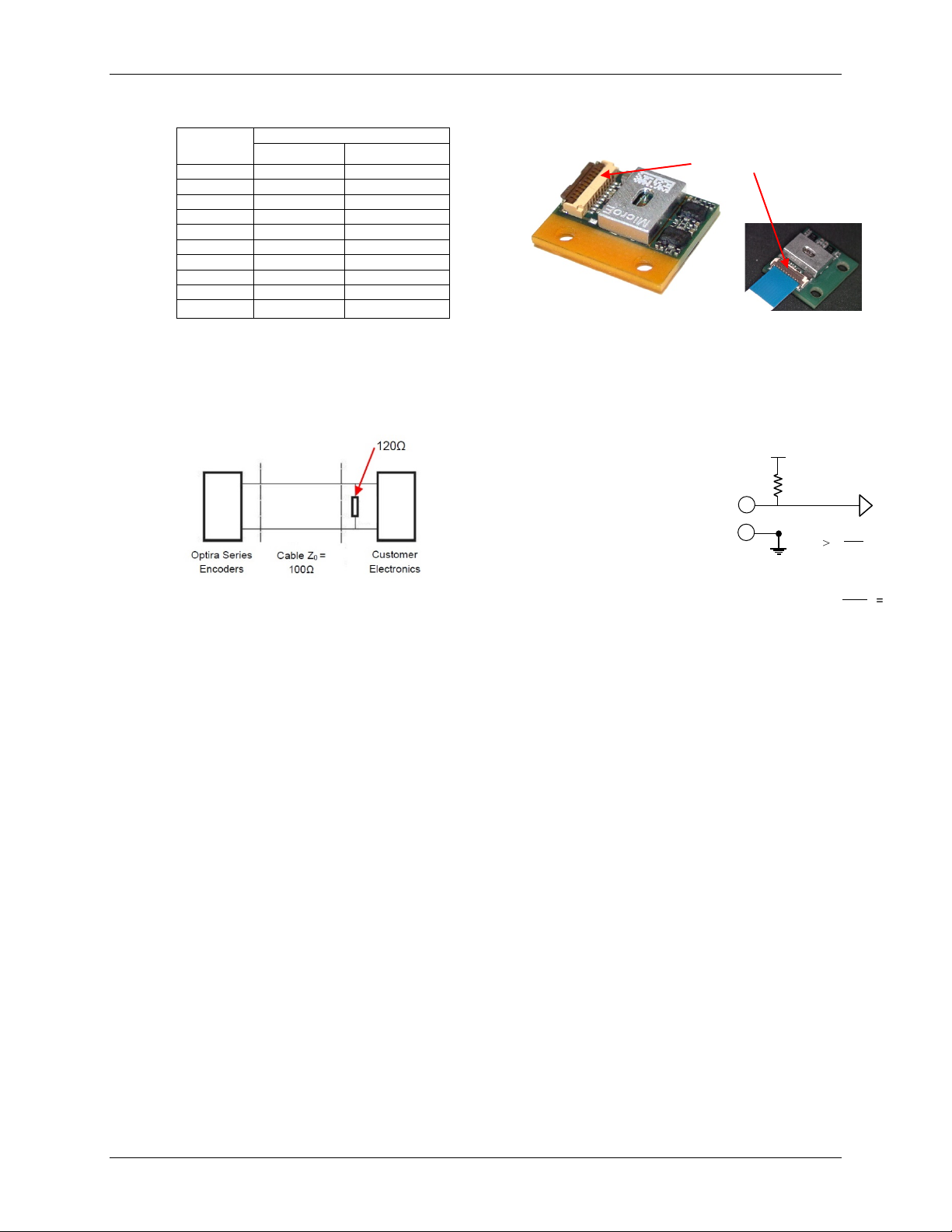

4.4 Optional Connector and Calibration Board

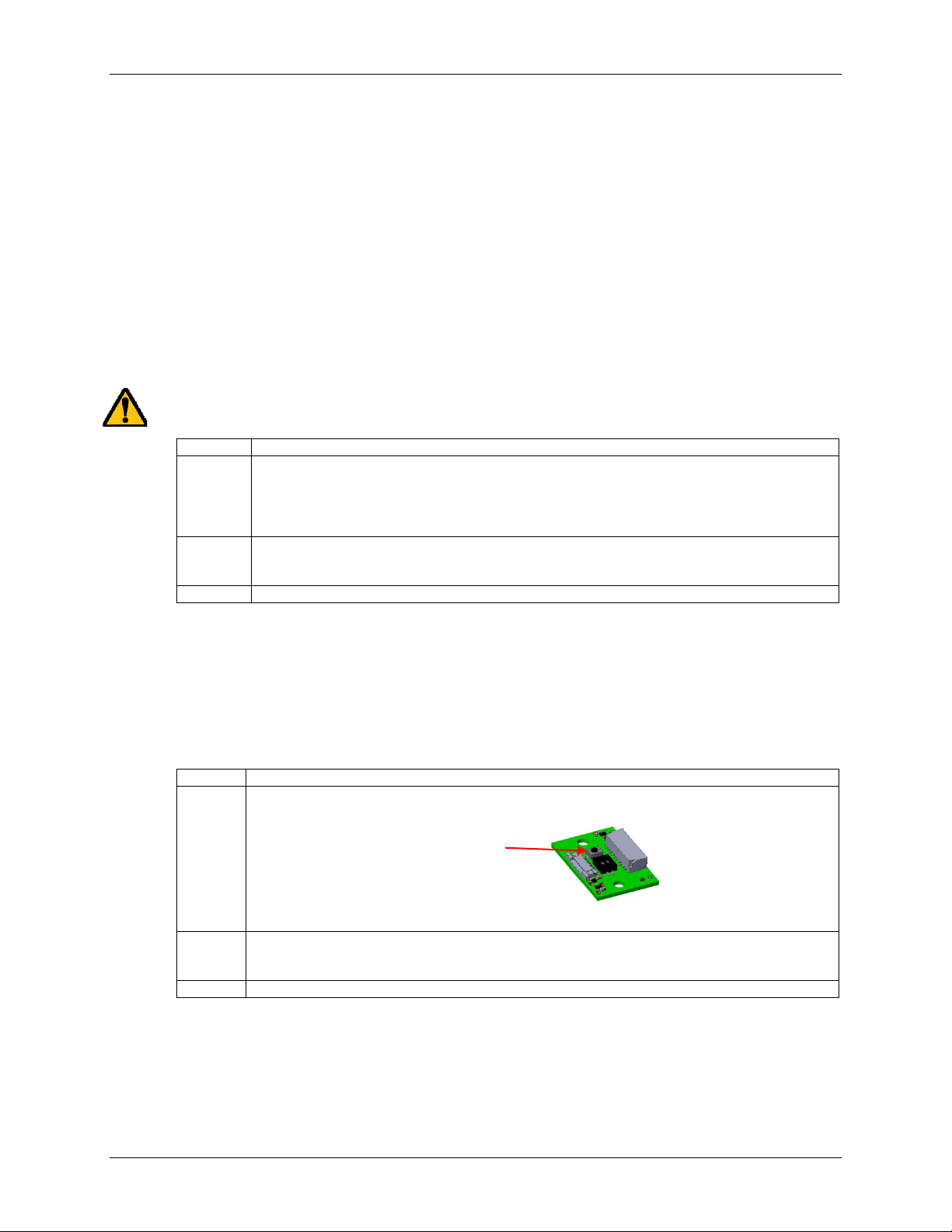

This section contains information needed to install the optional Connector and Calibration Board.

LED Configuration Switch S2

Switch

Description

On

Off

1

Red Alarm LED (D2)

Alarm is active low

Alarm is active high

2

Green Power On LED (D1)1

Power On LED is On

Power On LED is Off

Default from factory: both S1 and S2 are set to ON.

Note1:S2 is not a power switch; intended only to turn LED off for light sensitive applications.

LED Configuration Switch (S2)

Calibration

Pushbutton (S1)

Green Power On

LED (D1)

Red Alarm

LED (D2)

Connector J2

Connector J1

J1 Pin 1

Note: Protect the

mounting area with

insulating material.

(Mounting Holes)

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 8 ©2018 Celera Motion

Recommended Customer Required Parts

The following parts or their equivalents are recommended for using the optional Connector and

Calibration board.

Item

Description

Custom Connector

Parts required to connect custom cable to header connector J2 (JST SM10B-

SRSS-TB):

•Mating Connector JST 10SR-3S

•Crimping Tool JST YRS-859

•Terminal Connector JST SSH-003T-P0.2 (28 – 32 AWG TIN)

Screwdriver

WiHa 26008. Small plastic screw driver to change settings on the DIP switch on

the Connector and Calibration Board.

FFC Cable

Flexible Flat Cable (FFC): 0.5 mm, Type 1, 10 P. Maximum length of 5 m.

Refer to manufacturer’s specification.

If long flex cables are needed, contact Selmark Associates for Parlex cables or

contact another equivalent manufacturer.

5.0 Design Mounting

This section contains instructions for designing the mounting scheme for installing the sensor. A

benching edge is recommended to locate the sensor to meet mechanical mounting tolerances.

Refer to the Interface Drawing for recommended location and height of edge. Use the following

reference surfaces for sensor installation.

6.0 Sensor Installation

This section contains instructions for installing the sensor and the optional connector and

calibration board.

6.1 Install Sensor

Note: Tape or glass scales must be installed before installing the sensor. Refer to the Optira

Tape and Glass Scales Installation Manual for instructions.

Refer to the Optira Interface Drawing ID-00400 for details for sensor installation. A benching edge

is recommended to locate the sensor to meet mechanical mounting tolerances. Refer to the

Interface Drawing for recommended location and height of edge.

Note: When installing sensor, ensure that the detector is always facing grating.

Mounting surface

Benching edge

Installed tape scale

Reference Surfaces

A

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 9 ©2018 Celera Motion

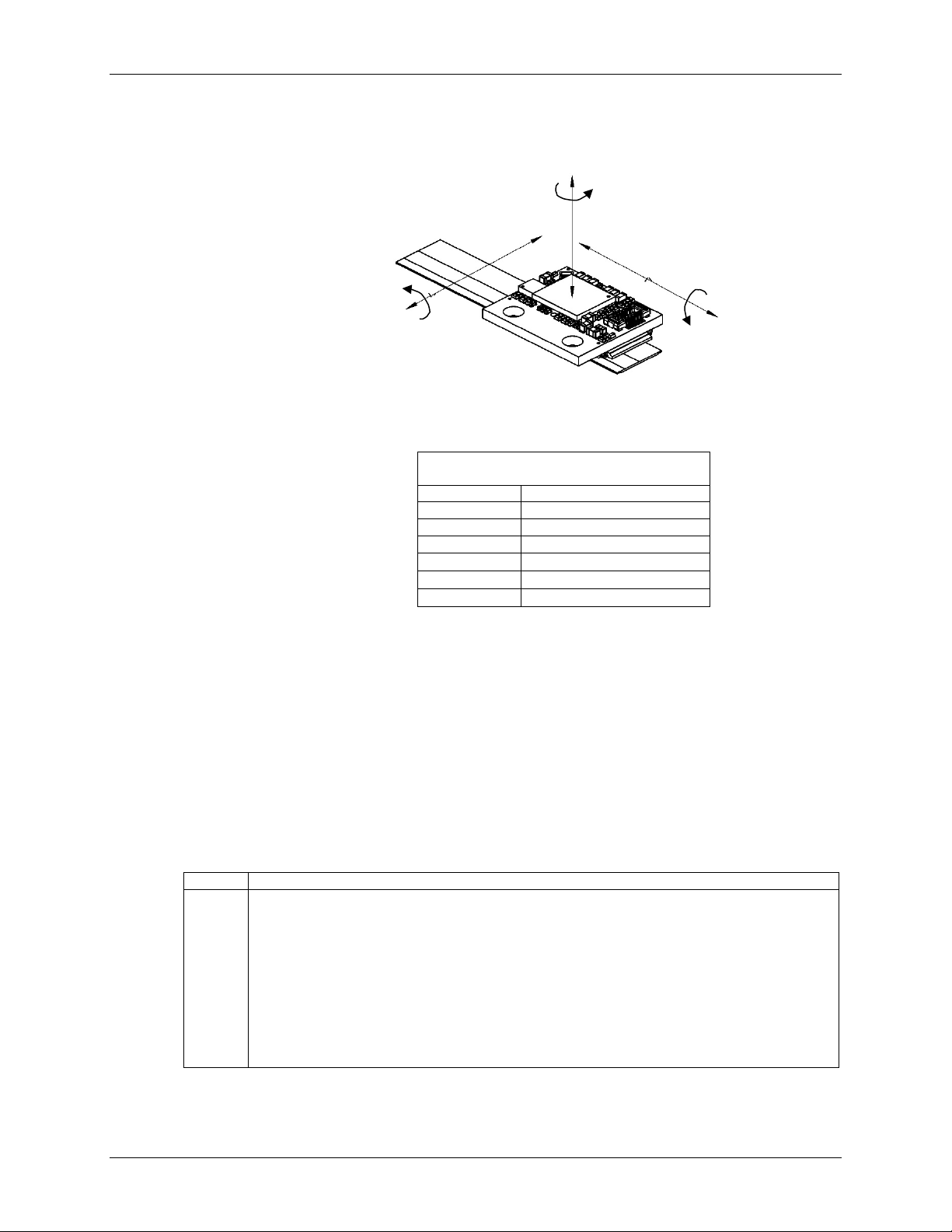

6.1.1 Sensor Mounting Orientation and Tolerances

Refer to the following specifications when installing and aligning the Optira sensor.

Orientation

Tolerances

Optira Series Encoders

Sensor Alignment Tolerances

Axis

Alignment Tolerance

X

Direction of Motion

Y

± 0.15 mm

Z

± 0.15 mm

θX

± 1.0°

θY

± 1.0°

θZ

± 2.0°

Note: Tolerance for each axis is specified independently, assuming nominal alignment in other

axes.

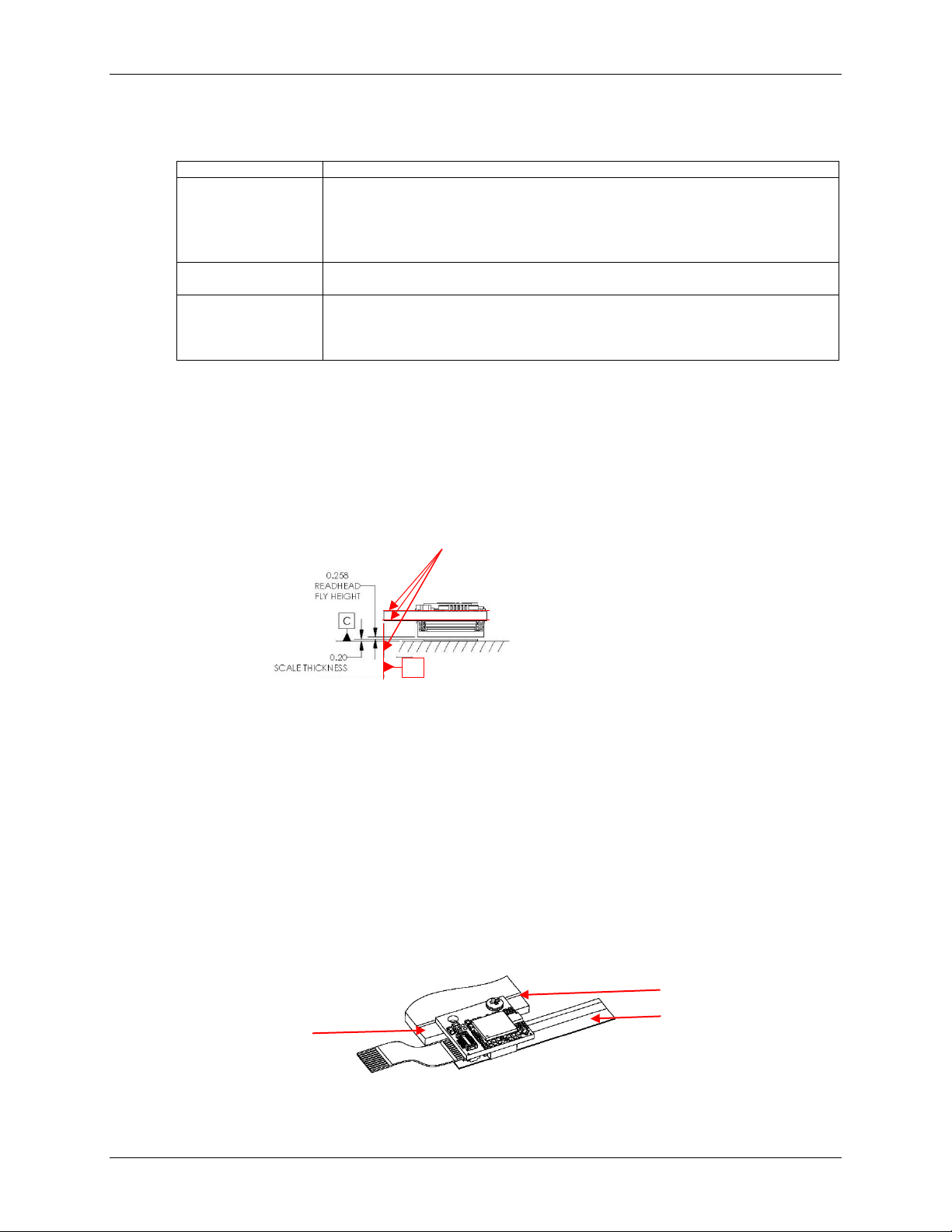

6.1.2 Top Mounting

Perform the following steps to install sensor. Benching the sensor is the preferred method for

installation and the sensor will then not require an alignment. Refer to sensor information in

Section 3.0 System Overview. For installing the sensor to a PCB, go to Section 5.1.3 PCB

Mounting.

Note: A scale must be installed before installing the sensor. Refer to the Optira Series

Encoders Tape and Glass Scales Installation Manual for instructions.

Step

Action

1.

Attach the FFC cable to the sensor ZIF connector J1 before installing sensor (see note

below about space restriction). Be careful when connecting/disconnecting the FFC to not

damage the connector.

Note: Once sensor is mounted, there is not sufficient space to safely disconnect or connect

the FFC cable. As there is limited clearance between the ZIF connector and the scale

surface, it is recommended that the FFC be mounted to the connector prior to

mounting the sensor.

Tip: For high mechanical stress environments, secure the FFC to ZIF connector using

non-conductive epoxy.

ϴZ

ϴY

ϴX

Z

X

Y

Sensor Axes

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 10 ©2018 Celera Motion

Step

Action

2.

Z-Height:

If Z-Height is not adjustable, firmly place sensor against benching edge.

If Z-Height is adjustable, go to Step 5.

3.

Use two M1.6 or 0-80 screws to attach the sensor and tighten per torque specification:

0.34Nm

(3 inch-lbs.) maximum.

4.

Connect sensor to customer’s electronics or to the optional Connector and Calibration

Board.

Result: Sensor installation is complete for benching install. Alignment not required with

benching installation. If sensor has an LSB index, go to Section 5.1.5 LSB Index

Calibration.

5.

If Z-Height is adjustable:

Use the Z-Height Shim Spacer (part of optional development kit) to set the proper gap

between the sensor’s riser and the top of the scale (0.493 mm). Refer to the Optira Interface

Drawing for details.

6.

Insert the Z-Height Shim Spacer between the sensor’s riser and the top of the scale.

7.

Fully tighten the two M1.6 or 0-80 screws to attach the sensor. Tighten screws per torque

specification: 0.34Nm (3 inch-lbs.) maximum. Adjust the Z-Height. The shim should move

with minimal friction between the riser and the scale. Remove shim.

8.

Connect sensor to customer’s electronics or to the optional Connector and Calibration

Board.

Result: Sensor installation is complete for adjustable Z-Height install.

Note: If sensor was not installed using benching, then go to Section 5.1.4 Sensor Head

Alignment Sensor Head Alignment to align the sensor.

Z-Height Shim Spacer

Side View of Sensor

Riser

Installed tape scale

Side View of Sensor

Insert the shim here between

bottom of riser and top of the

installed tape scale

Installed tape scale

Riser

Z-Height Shim Spacer

Benching edge

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 11 ©2018 Celera Motion

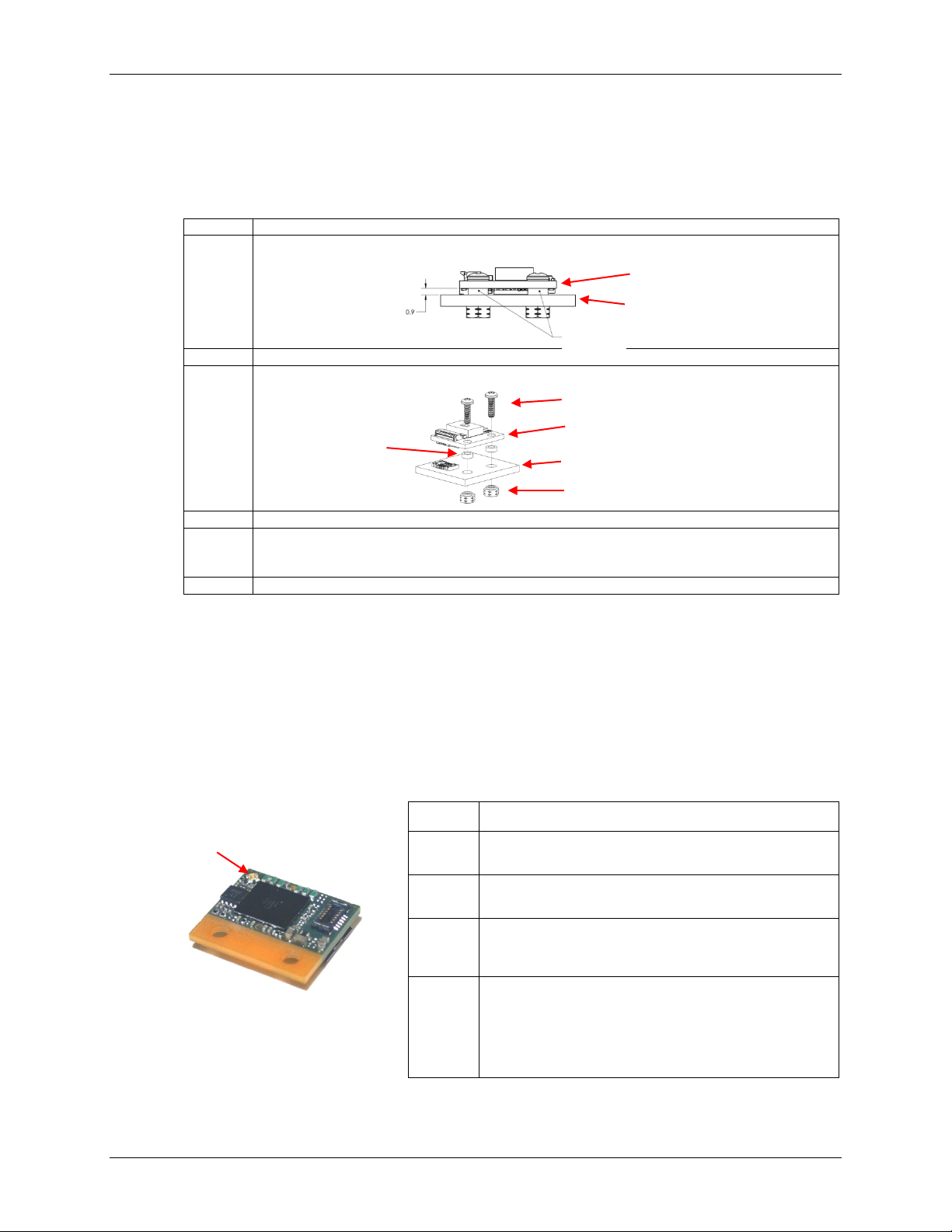

6.1.3 PCB Mounting

Perform the following steps to mount sensor to customer's PCB. Refer to sensor information in

Section 3.0 System Overview.

Note: A scale must be installed before installing the sensor. Refer to the Optira Series

Encoders Tape and Glass Scales Installation Manual.

Step

Action

1.

Use spacers to maintain sufficient space between sensor and PCB.

2.

Press sensor to PCB carefully ensuring good connection for mating connectors.

3.

Insert mounting screws between sensor and PCB through spacers.

4.

Attach surface mount fasteners securely.

5.

Install the PCB on the mounting surface referencing the appropriate datum surface as

shown in the Optira Interface Drawing. Use two M1.6 or 0-80 screws and tighten per torque

specification: 0.34Nm (3 inch-lbs.) maximum.

6.

Connect PCB to customer’s electronics or to the optional Connector and Calibration Board.

6.1.4 Sensor Head Alignment

6.1.4.1 Status LED Version A (Standard)

Alignment is positioning of the sensor with respect to the scale to achieve proper signal strength

from the count track and the index track. Proper sensor alignment may require minor adjustments

to the sensor position with respect to the scale.

Sensor alignment can be performed easily by using the sensor’s Status LED indicator, which

lights depending on sensor alignment as follows:

Note1: The Status LED can be ordered with all four colors available, or with only red available for

alarm indication (see Section 7.0 Order Guide).

LED

Color

1

System Status

Green

Optimal alignment:

Optimal position signal with minimum power consumption

Encoder system meets specification.

Greenish

Yellow

Good alignment:

Optimal position signal at specified power consumption

Encoder system meets specification.

Orange

Alignment could be improved but fully operational:

Sensor is reading position with marginal signal strength.

Encoder system functions but vector magnitude may not be 1

Vpp and SDE may exceed specification.

Red

Sensor fault:

Sensor is reading position with weak signal strength, or

Power supply is less than 4.2 V, or

Power supply is greater than 5.5 V, or

Sensor moving faster than 5.8 m/s.

Encoder system may not function properly.

Alarm signal will be asserted.

Sensor

PCB

Mounting Screws

PCB

Sensor

Surface Mount Fasteners

Spacers

Spacers

Status LED

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 12 ©2018 Celera Motion

LED Indications for Index Detection

•LED flashes bright when passing over index

•LED stays bright if stopped on index

Align Sensor

Perform the following steps to align the sensor:

6.1.4.2 Status LED Version B

Version B can be specified when there is a requirement for low ambient light. Version B operates

identically to Version A on each power-up state facilitating sensor alignment. After 5 minutes,

however, the LED operates as a fault indicator only.

If calibration is initiated after the 5 minute period the LED will blink as in Version A but will revert

to alarm indication only after calibration is complete.

6.1.5 LSB Index Calibration

Calibration is the process where the Least Significant Bit (LSB) index is set to its most stable

operating location, which is centered within the sensor’s 20 µm wide, raw Index Window (IW).

Calibration is only required for sensors with the LSB Index option (see Section 7.0 Order

Guide). Analog sensors or digital Optira sensors configured with the 20 µm Index Window do not

require calibration.

When to perform calibration:

•When installing the sensor for first time

•If the sensor is subsequently remounted

•If the scale is replaced

Step

Action

1.

Apply power to sensor.

2.

Ensure that the sensor’s mounting screws are loosely tightened. Slowly move the sensor by

allowing it to slide on the mounting surface until the Status LED illuminates green.

3.

Confirm that the green LED flashes brightly when passing over the index. If not, readjust the

sensor in the Y direction and repeat the above procedure.

4.

When alignment is completed, tighten the sensor mounting screws per the torque

specification: 0.34Nm (3 inch-lbs.) maximum.

5.

Confirm that the LED remains green over the full range of motion.

6.

If the sensor is not aligned over the entire range of motion:

•Loosen the sensor mounting screws and repeat this procedure starting at Step 1.

•Confirm that the scale has been installed parallel to the motion axis and that the LED

remains green through the full range of motion.

Result: The LED remains green throughout travel and flashes over the Index.

ϴZ

Z

Slowly slide sensor on its mounting

surface in the Y or ϴZ directions

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 13 ©2018 Celera Motion

After installing and aligning the Optira sensor, calibrate the sensor using one of the following

methods:

•Manual Calibration

•Using the Calibration Pushbutton

Note: Ensure that the sensor has already been aligned prior to calibration.

Manual Calibration

Use the following instructions to perform a manual calibration when the optional Connector and

Calibration Board (Model PI-CB) is not present.

See Section 6.3 Sensor Connectors Pinouts for pinout details.

Note: Perform procedures below at ≤1 meter/second relative motion between the sensor and

scale.

Caution: Be careful when performing the following procedure since power is on and there is a

potential to damage equipment.

Step

Action

1.

Short the CAL signal to ground:

Connect a wire or jumper from the Cal signal on the sensor connector (pin 8 of J1 or JP1) to

ground (pin 10 of J1 or JP1) or to ground on the PCB.

Result: The system status LED starts blinking at a regular rate.

2.

Move the sensor over the index up to 20 passes (one pass is a single cycle back and forth).

Result: The LED stops blinking.

3.

Calibration is complete.

Using the Calibration Pushbutton

Use the following instructions to perform sensor calibration by using the Calibration Pushbutton

on the optional Connector and Calibration Board (Model PI-CB).

Note: Perform procedures below at ≤1 meter/second relative motion between the sensor and

scale.

Step

Action

1.

To start calibration, press the Calibration pushbutton (S1) on the Connector and Calibration

board.

Result: The sensor LED and the Alarm LED start blinking at a regular rate.

2.

Move the sensor over the index up to 20 passes (one pass is a single cycle back and forth).

Result: The LEDs stop blinking.

3.

Calibration is complete.

Note: To abort calibration, press the Calibration pushbutton again.

Calibration Pushbutton S1

Connector and

Calibration board

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 14 ©2018 Celera Motion

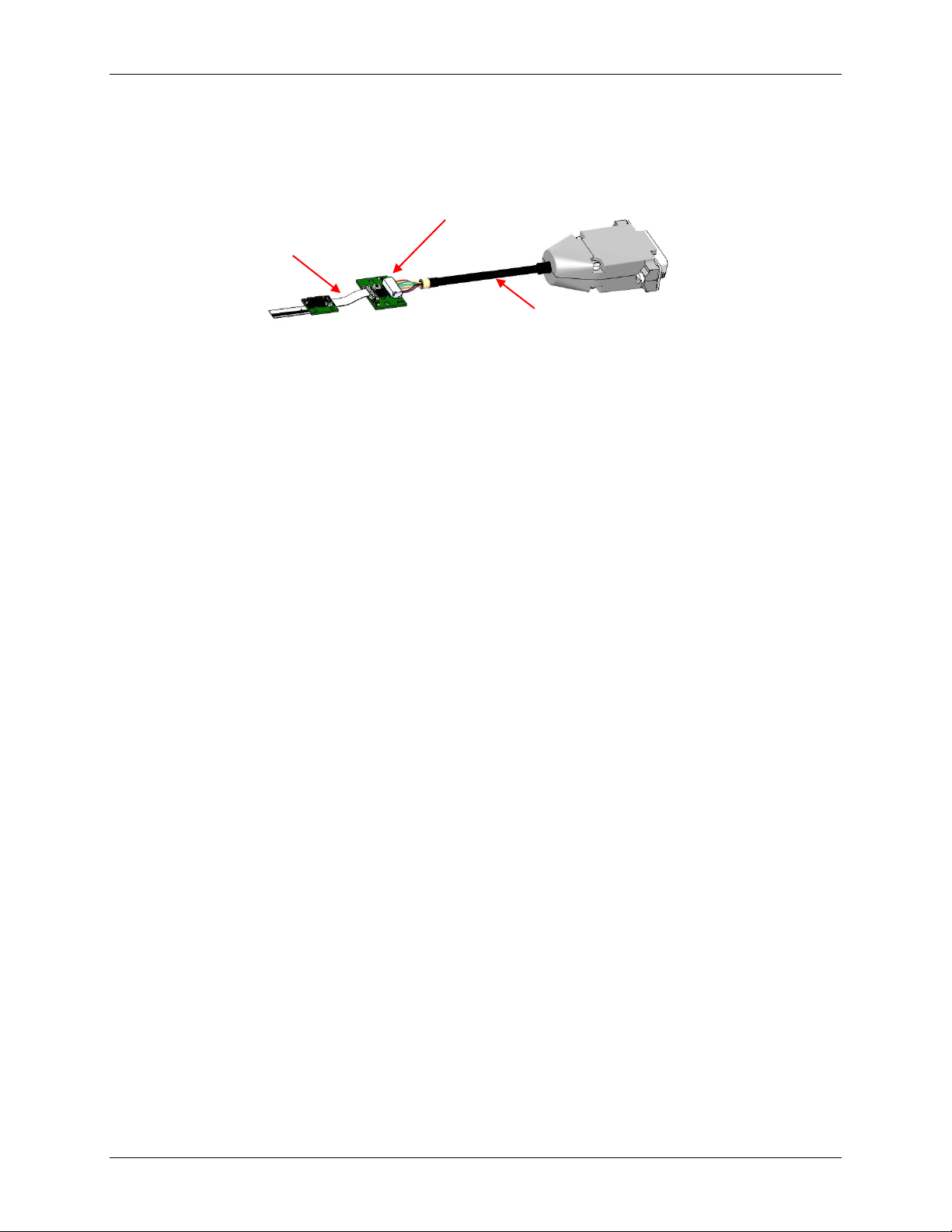

6.2 Install Optional Connector and Calibration Board

The optional Connector and Calibration Board can be connected to the sensor using cables in the

optional Development Kit or by using customer's wiring. Refer to the information in Section 3.0

System Overview.

Guidelines

•The optional Connector and Calibration Board can be mounted by using mounting screws

and standoffs or epoxy.

•Using Kapton tape is recommended if mounting directly to conductive surface without

standoffs.

•Use the board as an indicator of alignment by monitoring the alarm LED. Refer to

Section 5.1.4 Sensor Head Alignment to match Status Led on sensor and if Alarm LED

is configured as active high or active low.

Creating Custom Connector to Connector and Calibration Board

Use the crimping tool (JST YRS-859) with crimp connector terminals (JST SSH-003T-P0.2) to

connect custom cables to the mating connector (JST 10SR-3S) to J2 shrouded head connector

(JST SM10B-SRSS-TB).

Connector and Calibration Board

Connected to sensor using the

200mm FFC from the development kit To customer's electronics

Connected to customer's electronics using the

3m controller cable from development kit

Sensor

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 15 ©2018 Celera Motion

7.0 Appendix

7.1 Specifications

System

Operating and Electrical Specifications

Scales

Optira Series Encoders are compatible with Optira Tape

Scales, Linear Scales, and Rotary Glass Scales

Agency Standards Compliance in accordance with

Electromagnetic Compatibility Directive 2004/108/EC:

Scale Pitch 20 µm

EN55011, Class B:

EN 61000-4-3:

EN 60068-2-6:

EN 60068-2-27:

Radiated Emissions

Radiated Immunity

Vibration

Mechanical Shock

System

Resolution

5µm, 2.5 µm, 1 µm, 0.5 µm, 0.2 µm,

0.1 µm, 50 nm, 20 nm, 10 nm, 5 nm.

Analog 1 Vpp.

2,000 CPR – 75M CPR (rotary)

(specify resolution at time of ordering)

Power Supply Current

AquadB, 3.3 and 5 V

DC

±5%:

Analog, 3.3 and 5 VDC ±5%:

Ready Time:

<130 mA with 120Ω across A, B, I

<75 mA with no load

<100 mA with 120Ω across Sin/Cos, IW

<75 mA with no load

<0.5s once power >4.5 V

Accuracy

Tape

SDE:

Linearity:

Slope:

<100 nm RMS

<± 5 µm (max/meter)

<±150 µm/m

Temperature

Operating:

Storage:

0°C to 70°C

-20°C to 85°C Temperature

Linear Glass

SDE:

Total Accuracy:

<100 nm RMS

<±1 µm/m1

Humidity

Operating:

Storage:

Up to 85% RH, non-condensing

Up to 85% RH, non-condensing

Rotary Glass Total Accuracy: ±2 arc-seconds2

Vibration 10 g, 55 Hz to 2 KHz

Sensor Size and Weight

Mechanical

Shock

500 m/s2, 6 ms, ½ sine

Length

Width

Height

Outputs

Digital A-quad-B. A, B, Index outputs are differential

Alarm is single-ended open collector

Analog outputs are differential sine and cosine

Dimensions (mm): 13.0 11.4 3.7

Weight: <1.5 g sensor head

Sensor Cable

ZIF Flat Flexible Cable (FFC)

10 pins; length up to 5 m.

Signal Levels

A/B/I (differential); RS-422 compatible

A/B/I (single-ended): Voh min: Vcc - 0.4 VDC, Vol max: 0.4 VDC,

Alarm: Voh min: Vcc, Vol max: 0.4 VDC

Analog: 1 Vpp, 2.5 V offset @ 5 VDC; 1.65 V offset @ 3.3 VDC

Reliability Information

MTBF >200,000 hours under normal operating conditions

(calculated using MIL-STD-217)

Notes:

1. 130 mm or less

2. 125 mm diameter, excludes eccentricity

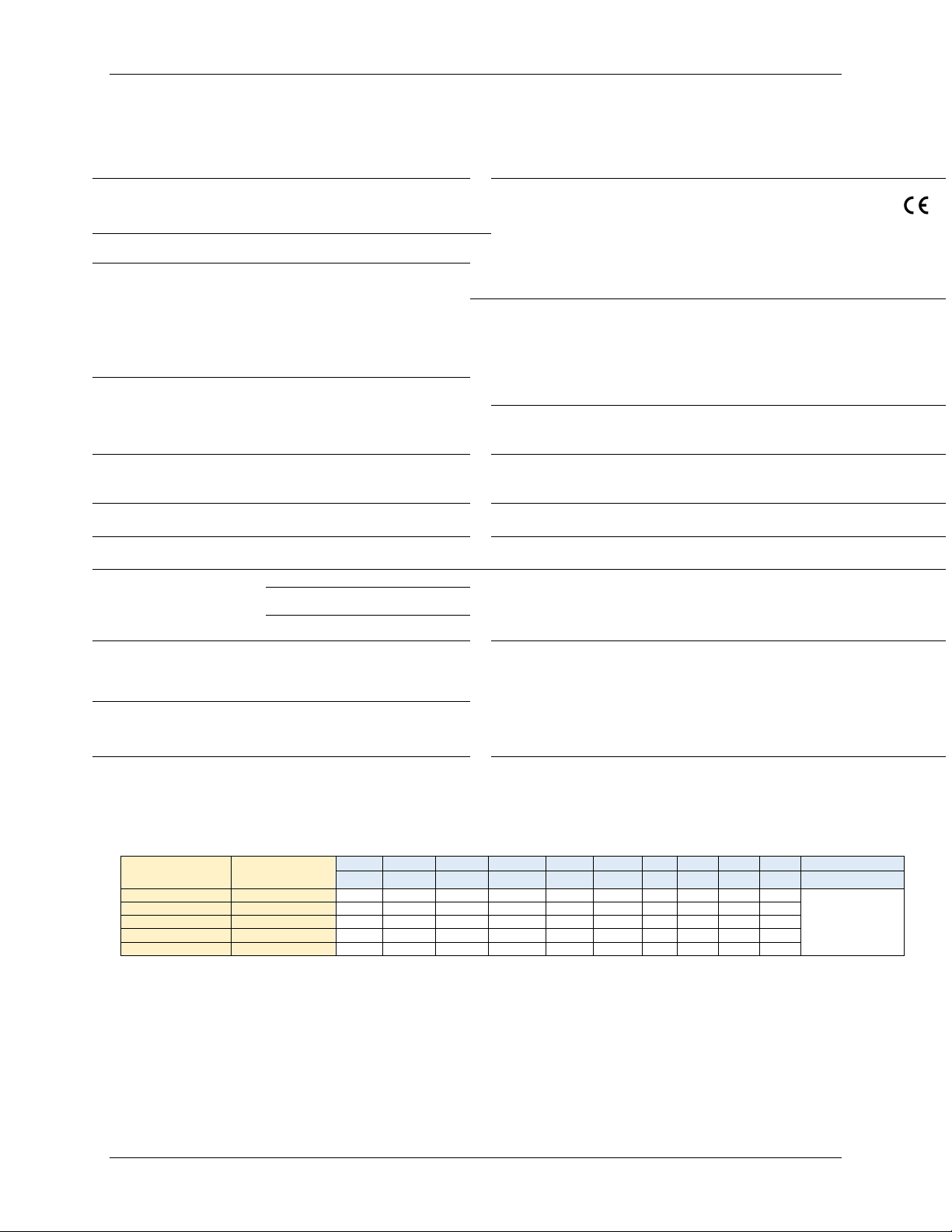

Maximum Velocity – Quadrature Output

Maximum Velocity (before Overspeed Buffer Protection3) vs. Interpolation Depth

Controller Recommended

AqB Maximum State

Rate (MegaStates/Sec)

Actual Encoder AqB

Maximum State Rate

(MegaStates/Sec)

5000

2500

1000

500

200

100

50

20

10

5

Resolution (nm)

4 8 20 40 100 200 400 1000 2000 4000

Interpolation Depth

20

14.50

4000

4000

4000

4000

2900

1450

300

290

145

72

Maximum

Velocity (mm/s)

10

7.25

4000

4000

4000

3625

1450

725

300

145

72

36

5

3.63

4000

4000

3625

1812

725

362

181

72

36

18

2

1.45

4000

3625

1450

725

290

145

72

29

14

7

1

0.73

3625

1812

725

362

145

72

36

14

7

3

Notes3:

1. Optira implements Overspeed Buffer Protection (OBP). No AqB counts are lost for velocities below 4830 mm/s even if the

maximum specified rate is exceeded. If the velocity exceeds the specified state rate, the AqB counts are buffered (buffer

length = 21 m at 4000x interpolation depth) and transmitted at the specified state rate.

2. The ALARM bit sets TRUE at 4 m/s, however, Optira will continue to produce valid AqB outputs up to

6 m/s although accuracy specifications are no longer guaranteed.

Maximum Velocity (Analog)

Sine/Cosine Vector Magnitude: > 0.5 Vpp at 4 m/s

Contact Celera Motion to discuss higher speed applications.

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 16 ©2018 Celera Motion

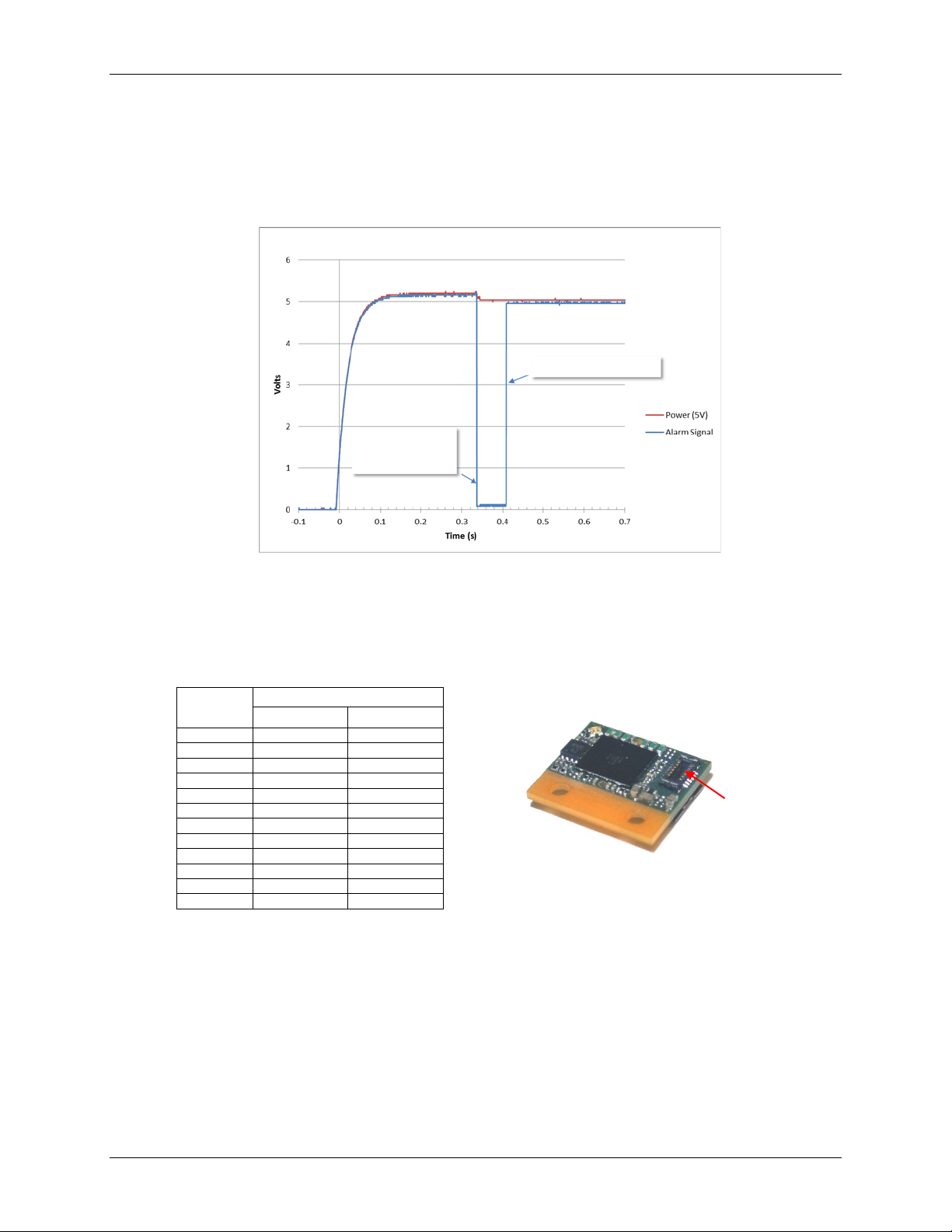

7.2 Power-Up Timing

The Optira encoder will be ready 420 ms after the 3.3 V or 5 V supply rises, during which the LED

will flash red and the Alarm signal will transition true. The encoder will be ready once the Alarm

transitions false per the following chart (5 V model is shown; chart also applicable for 3.3 V

model):

7.3 Sensor Connectors Pinouts

The following are the pinouts for the two connectors on the Optira sensor.

JP1 – Low Profile Board-to-Board Header Connector

Manufacturer Part Number: Molex®501594-1211

Pin

Number

Signal

A-quad-B

Analog

1

A+

SIN+

2

A-

SIN-

3

B+

COS+

4

B-

COS-

5

Index+

Index+

6

Index-

Index-

7

Alarm

Alarm

8

CAL

CAL

9

PWR

PWR

10

GND

GND

11

NC

NC

12

NC

NC

NC – No Connect

JP1 – Board-to-Board Header

Mating Connector1

Optira Sensor Top View

Note

1

: The 12-pin header mating connector has a limited

durability of 20 mating cycles maximum.

Optira Power Up Timing (low true Alarm)

Optira ready (420ms typ)

Internal Optira Reset

LED = red

Alarm = true

MicroE Optira Installation Manual Celera Motion

IM-1001 | REV181211 Page 17 ©2018 Celera Motion

J1 - ZIF Connector

Manufacturer Part Number: Hirose®FH33J-10S-0.5SH(10)

Pin

Number

Signal

A-quad-B Analog

1

A+

SIN+

2

A-

SIN-

3

B+

COS+

4

B-

COS-

5

Index+

Index+

6

Index-

Index-

7

Alarm

Alarm

8

CAL

CAL

9

PWR

PWR

10

GND

GND

7.4 Recommended Signal Termination

Note: Below values are applicable for 5 V models only.

Digital/Analog Outputs Alarm Circuit Example

Alarm output is an open collector

circuit that is factory programmable:

either active high or active low;

specify when ordering. Alarm requires

an external pull-up resistor. See

customer-supplied circuit example on

right.

Note: Maximum cable length is 5 m. Contact MicroE Applications Engineering if longer lengths are

required.

J1 ZIF Connector

Optira Sensor Bottom View

R > Vcc

8mA

Vcc ≤ 5.5V

= 688Ω

R > 5.5V

8mA

R

Vcc

P7

P10

Alarm

Table of contents

Other Novanta Media Converter manuals

Popular Media Converter manuals by other brands

KanexPro

KanexPro EXT-SDI3G user manual

Avenview

Avenview C-COMPVGA-HDMI user guide

Denon

Denon DA-300USB Getting started

Hall Research Technologies

Hall Research Technologies SP-HD-8A user manual

TR-Electronic

TR-Electronic CEV115M 8192/4096 V000 PROFIBUS 85ZB14N manual

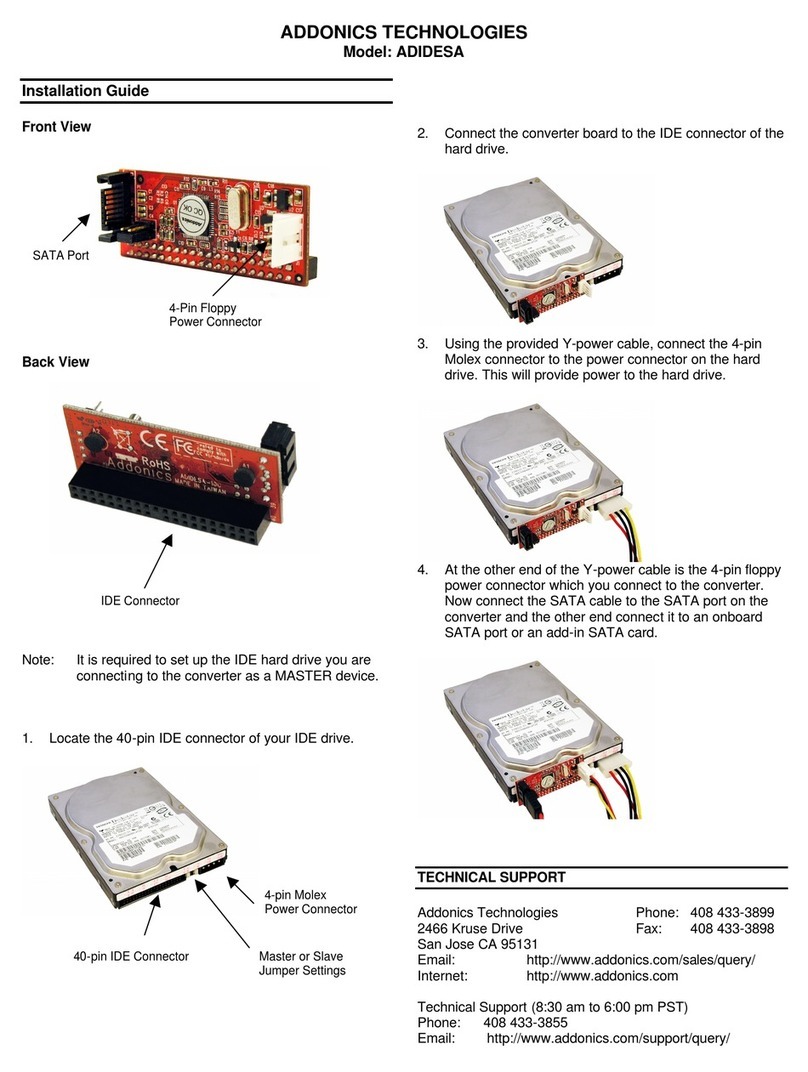

Addonics Technologies

Addonics Technologies ADIDESA installation guide