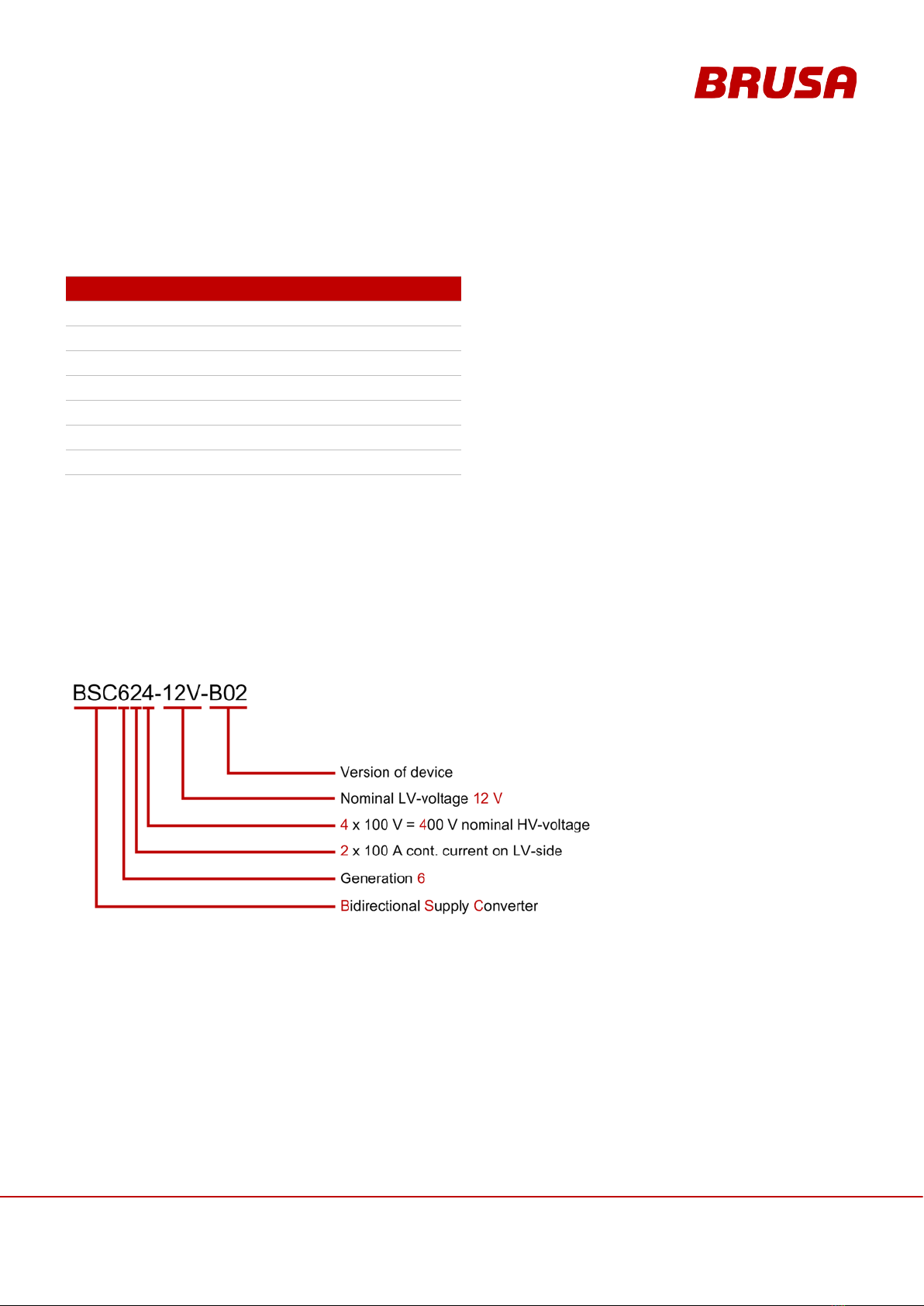

Technical information

and start-up

6.2 Technical properties.................................................................................................................25

6.3 Block diagram BSC624-12V-B .................................................................................................25

6.4 Basic function / EMC concept...................................................................................................26

6.4.1 Topology benefits..............................................................................................................26

6.4.2 Internal current supplies....................................................................................................27

6.4.3 LV filter concept ................................................................................................................28

6.4.4 HV filter concept................................................................................................................29

6.4.5 AUX filter concept .............................................................................................................30

6.5 Warnings on the device............................................................................................................31

6.6 Vehicle installation basic principle............................................................................................32

6.7 Safety concept vehicle installation............................................................................................33

6.7.1 Principle of operation Interlock ..........................................................................................33

6.8 Overview of the main structural components............................................................................34

6.9 Dimensions and installation information ...................................................................................35

6.9.1 Fixing points......................................................................................................................35

6.9.2 Dimensions .......................................................................................................................36

6.9.3 Installation position............................................................................................................36

7Electrical interfaces...........................................................................................................38

7.1 Pin assignment of control connector (device side)....................................................................39

7.1.1 Pin 1 GND.........................................................................................................................40

7.1.2 Pin 2 AUX .........................................................................................................................41

7.1.3 Pin 3 EN............................................................................................................................42

7.1.4 Pin 4 DO0 – pin 7 DO3......................................................................................................43

7.1.5 Pin 8 PG1, pin 14 PG2, pin 15 PG3 ..................................................................................44

7.1.6 Pin 9 CNL, pin 10 CNH .....................................................................................................44

7.1.7 Pin 11 TXD, pin 12 RXD....................................................................................................45

7.1.8 Pin 13 PRO.......................................................................................................................46

7.1.9 Pin 16 DI0, pin 17 DI1, pin 18 DI2.....................................................................................46

7.1.10 Pin 19 IL1, pin 20 IL2 ........................................................................................................47

7.1.11 Pin 21 AI1, pin 22 AI2, pin 23 AI3......................................................................................49

7.2 Pin assignment of HV power connector (device side)...............................................................50

7.3 Pin assignment of LV power connector (device side) ...............................................................50

8Connections.......................................................................................................................51