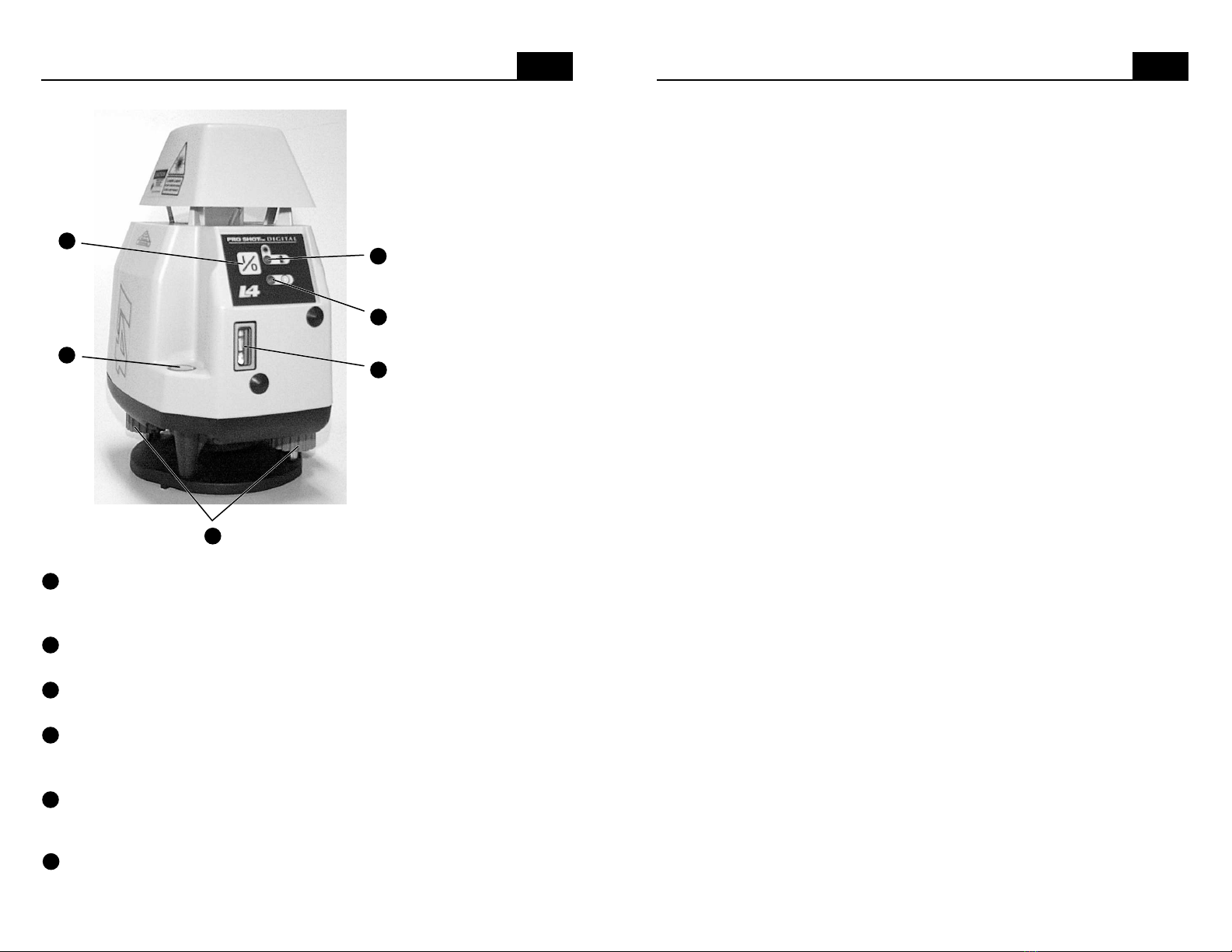

Controls and Displays

•

L4

+

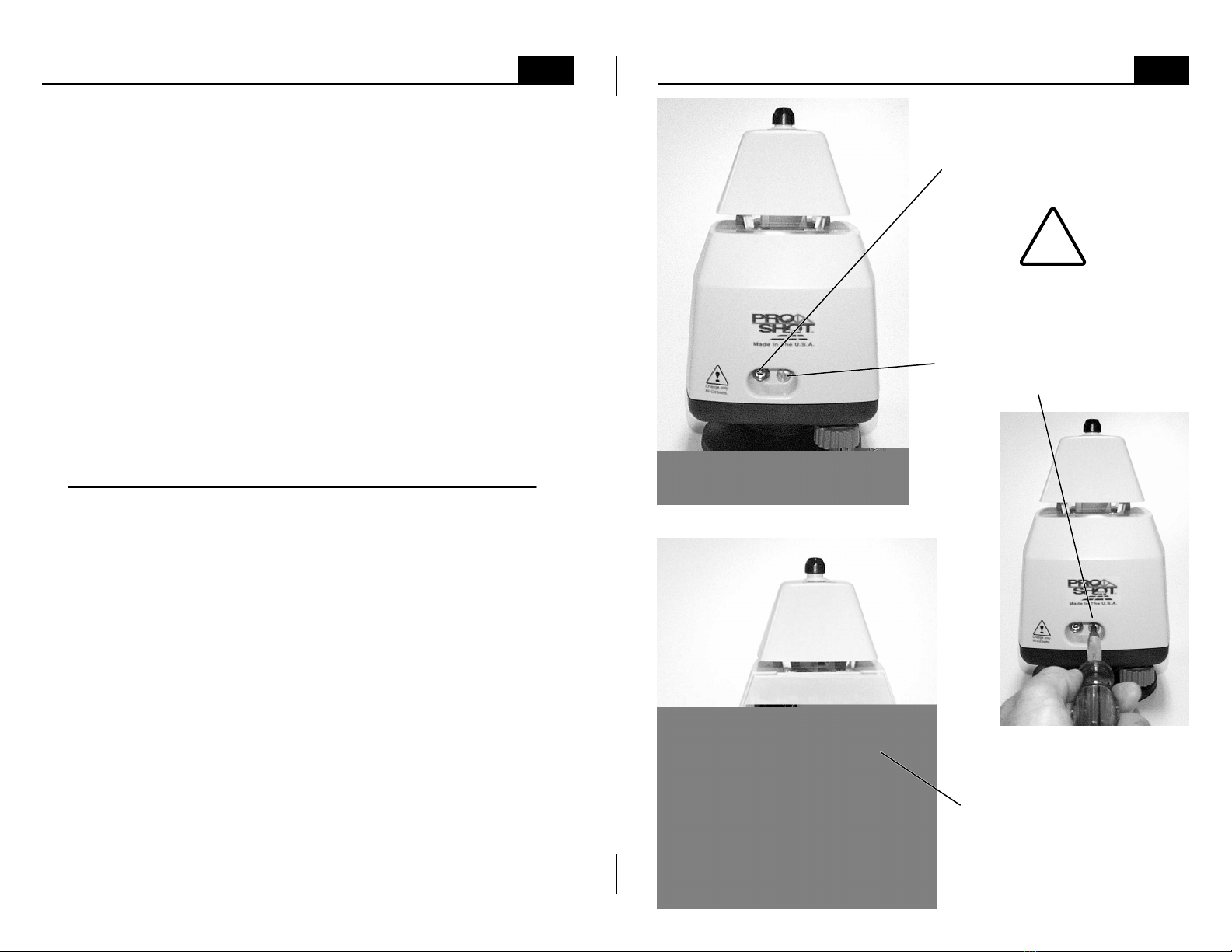

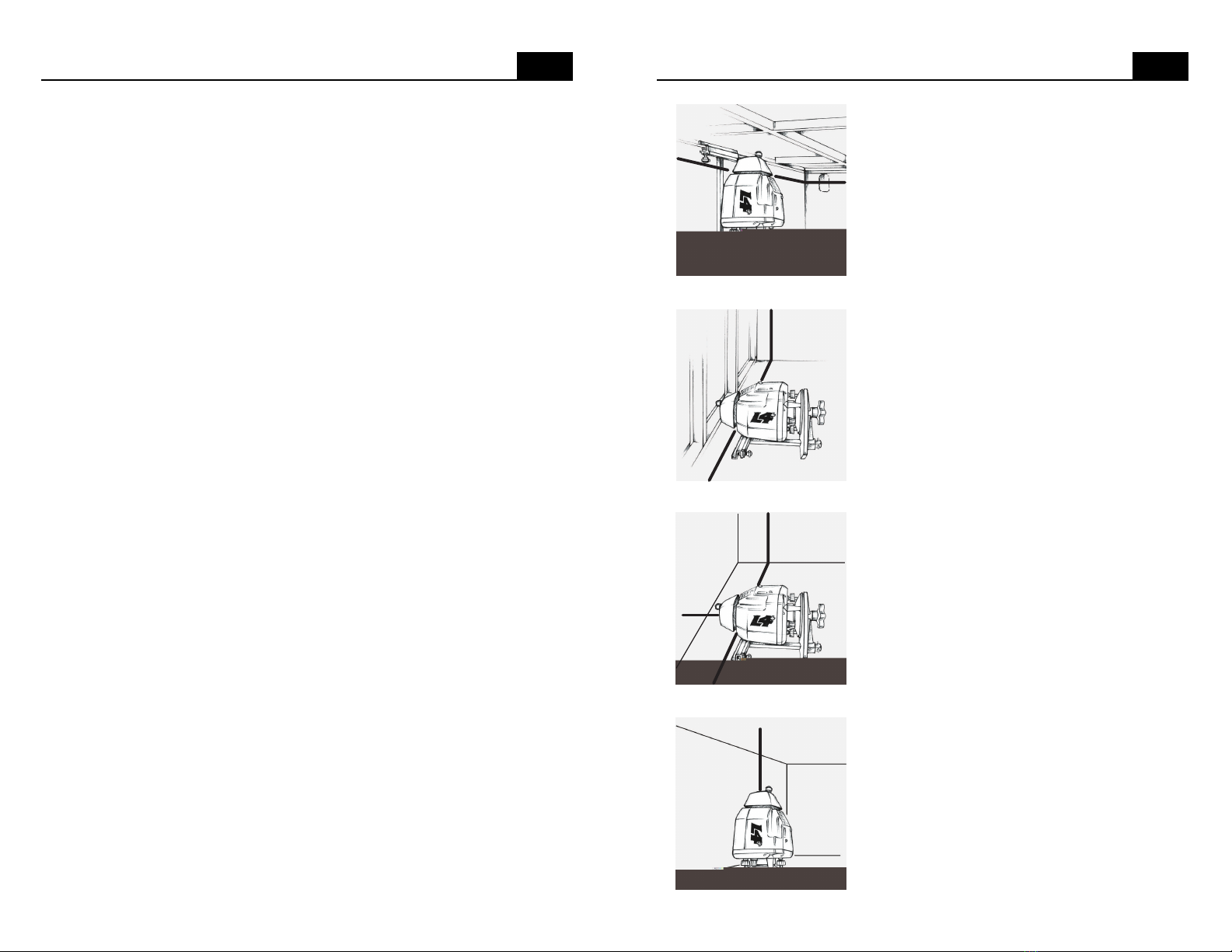

note: The leveling screws are

at 90ºto the leveling pivot

point, which is directly below

the circular vial. As you face

the control panel and look

down at the circular vial, the

leveling screw on your right

controls bubble movement

from left to right. The leveling

screw at the back, below the

battery door, controls bubble

movement from front to back.

Turning the leveling screw on

your right in a clockwise

motion will move the bubble to

the right and turning the back

leveling screw in a clockwise

motion will move the bubble to

the back. Turning each screw

counter-clockwise will have

the opposite effect.

Power button • Press the power button to turn the laser on or off.

Circular level vial • Indicates when the laser is close enough to level to

allow the automatic compensator to function.

Leveling screws • Used to center the bubble in the circular level vial.

The knobs are also used during vertical alignment (see page 13)

Leveling limit indicator • If the L4+is powered on, but not level enough

to automatically compensate, the limit indicator will flash, the rotating

mirror will not spin, and no laser beam will be projected.

Power and low battery indicator • Displays a green light when the laser

is powered on. The light will flash red if the batteries need to be replaced.

Speed control buttons • The (+) and (-) buttons adjust rotation speed. A

single push will make the speed slightly faster or slower. If you push and

hold the (+) button, the rotation will adjust to full speed. You will know

that full speed has been reached when the green power indicator flashes.

If you push and hold the (-) button, the rotation will slow and then stop.

Beam aiming knob • When the rotation is stopped, push and turn this

knob to aim the beam. Push the knob in and hold it in while turning.

Vertical vial • The vertical vial is used to plumb the plane of laser light

when the laser is in the vertical mode (see page 13).

3

14

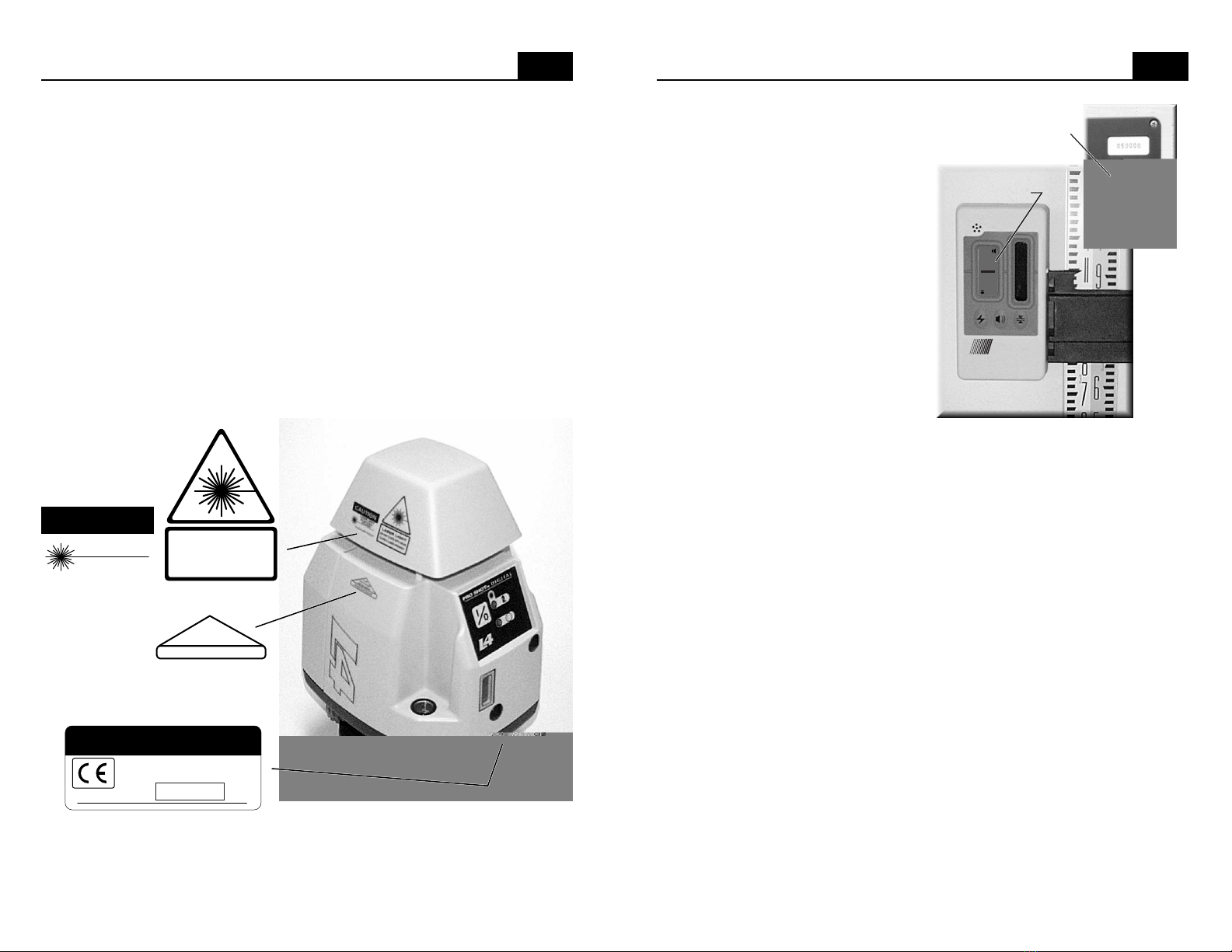

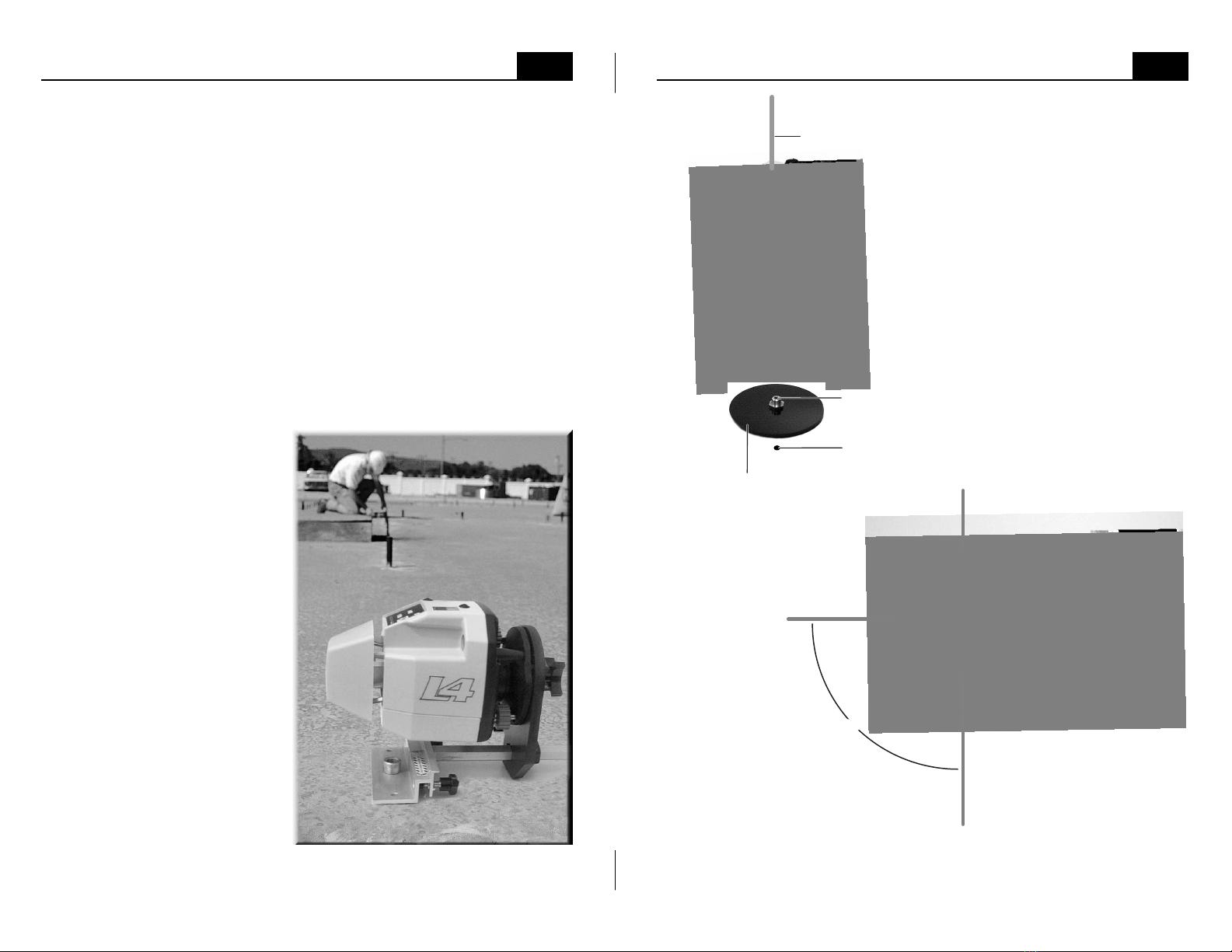

Checking & Adjusting Calibration

Calibration is your responsibility, check it often.

Although the L4 and L4+are exceptionally rugged lasers, it is well worth the

effort to check calibration before you first use them and then at regular

intervals to insure that you are doing the highest quality work possible.

Always check calibration if the laser has been handled roughly.

Calibration procedure.

1. Attach the laser to a stable tripod or stand approximately 100 feet (30m)

from a wall or other stable vertical surface. We will call the vertical surface

the target. Make the tripod head level enough to allow the laser to be aimed

in different directions with minimal re-leveling of the circular level vial.

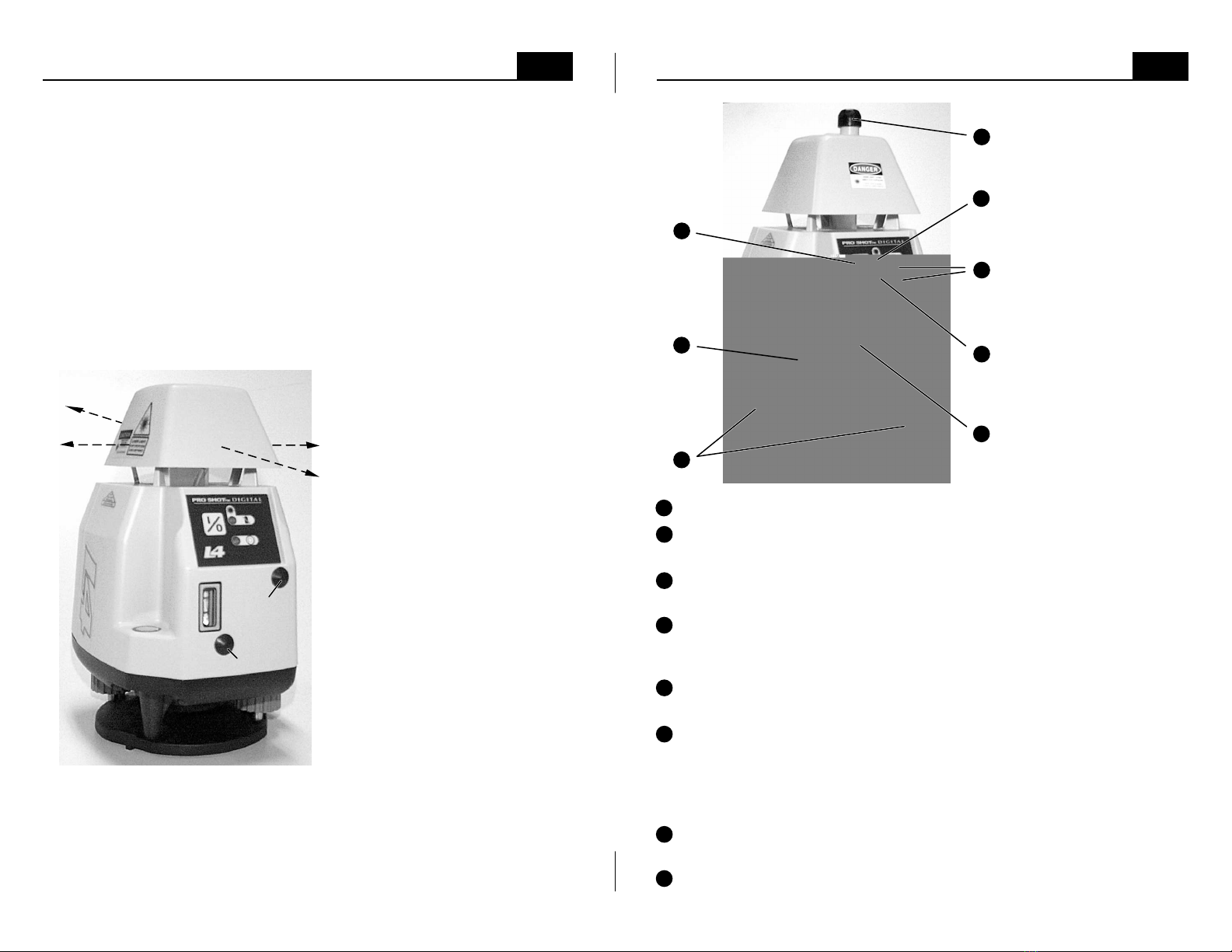

2. Turn the entire laser so that either direction of the x-axis (picture below) is

aimed at the target. Note: the axes are the same for both models.

3. Center the circular level vial

and turn the laser on.

4. Take the receiver to the

target and find the height of the

laser beam. All receivers have

a "deadband" at their center.

The most precise way to take a

reading is to make two marks.

Slowly move the receiver from

above until you get an on-grade

display and make a mark. Next,

slowly move the receiver from

below until you get an on-grade

display and make a second

mark. Half way between these

two marks is the exact reading.

5. Return to the laser and rotate

it 180 degrees. The opposite X-

axis direction should now be

aimed at the target. Re-center

the bubble in the circular level.

Find and mark the laser beam

height at the target.

6. The difference between the two marks (if any) is double the difference

between how the laser is calibrated and true level for the X-axis. Half way

between these two marks is true level. Make a long mark at true level. If the

difference between either outer mark and true level is within your working

tolerance, go on to step 9. If not, continue with the next step.

+X axis

-X axis

-Y axis

+Y axis

X axis

Y axis

1

5

8

3

2

6

7

4

5

8

6

7

4

1

3

2