2. INSTALLING THE CS OEM SENSOR HEAD SERIES

Installation must be performed by an operator qualified to

the use of voltage devices. LaserPoint is in no way liable for

any damage resulting from misuse, careless or use above

rated limits for the instrument.

2.1 -General

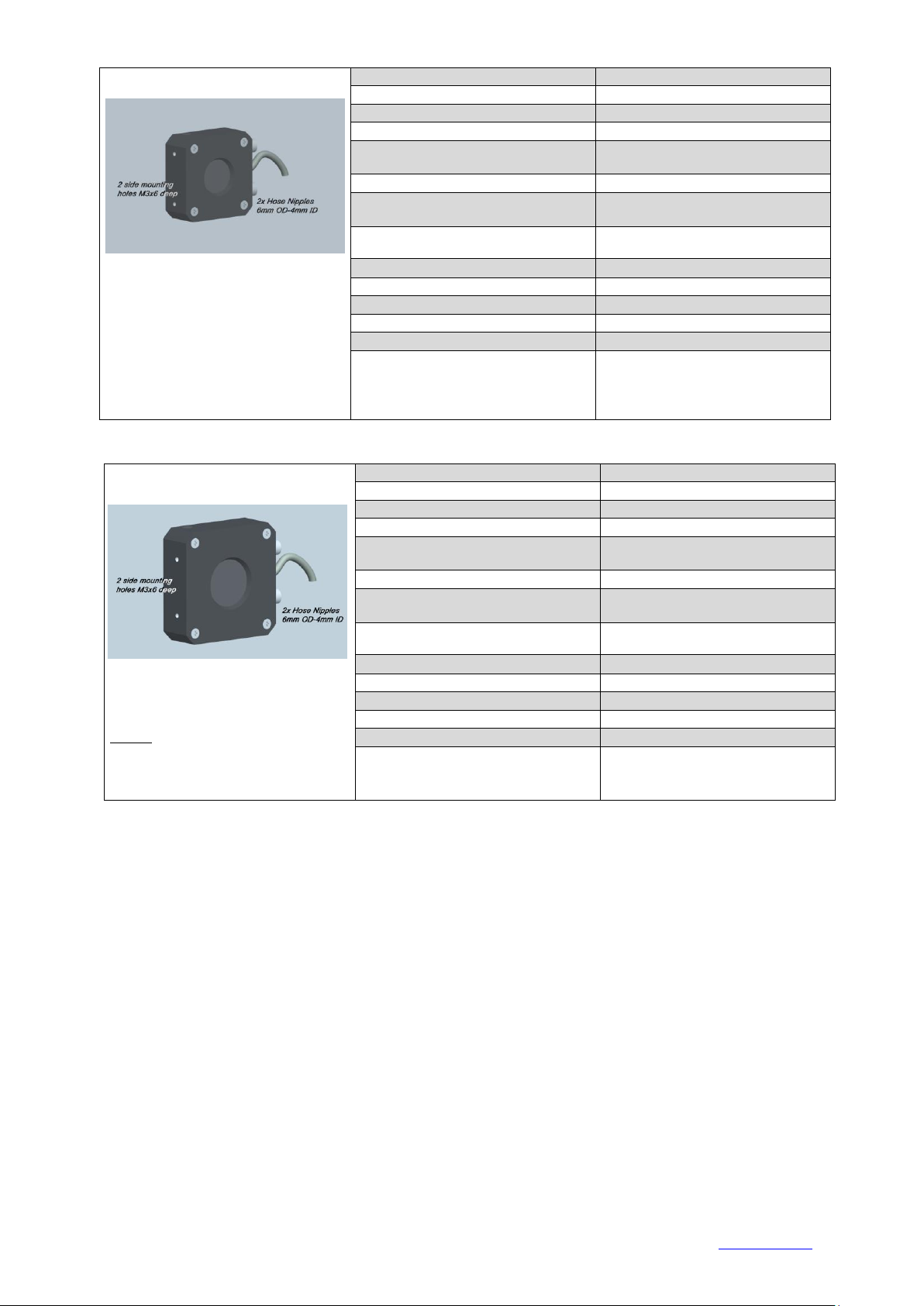

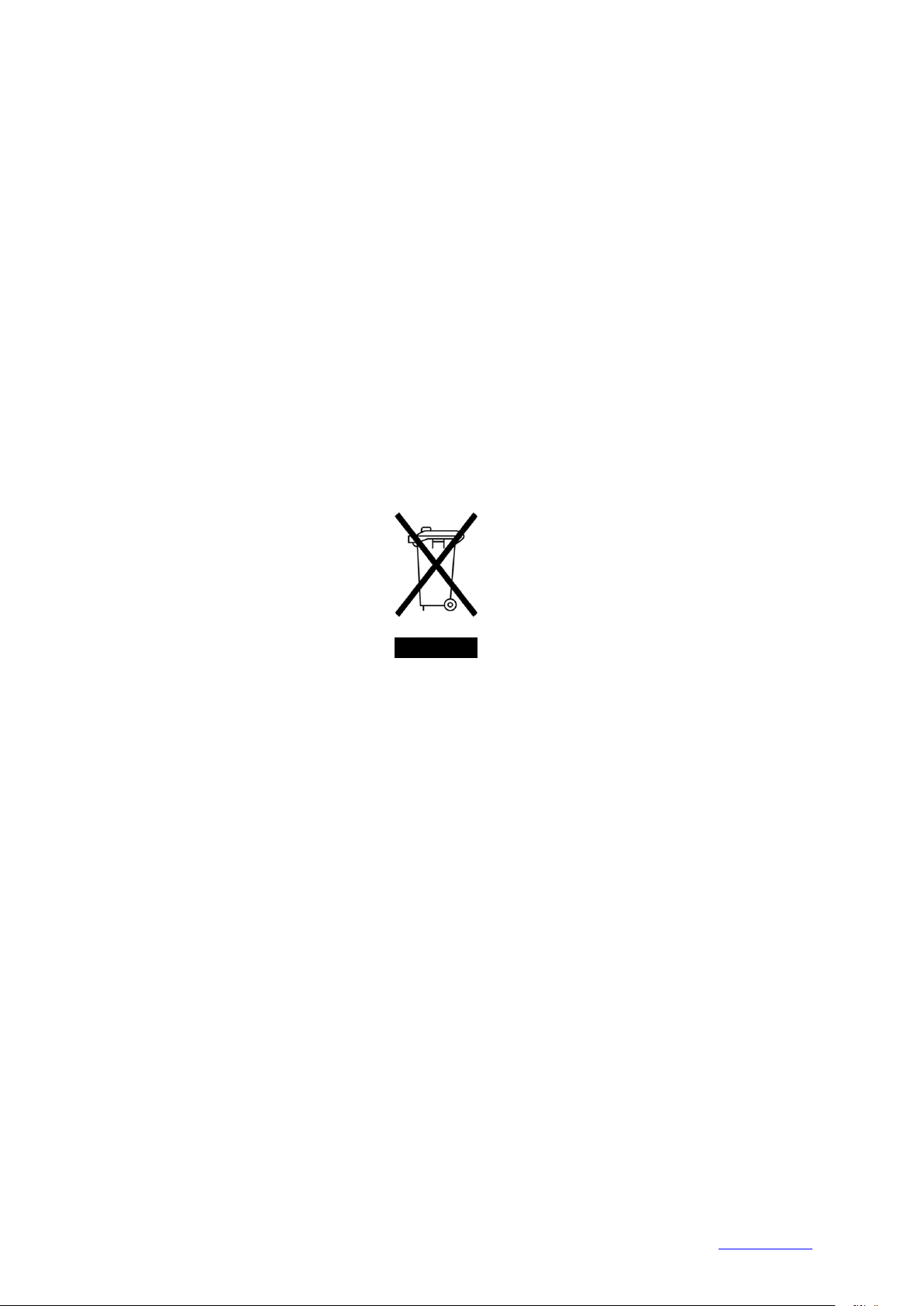

This series includes compact, conduction or water cooled

heads: the setup is made by sensor disk,

housing and a connecting device

(LaserPoint’s Intelligente Identification

System-IIS, BNC connector or Pigtail output).

The head has been previously mounted and tested in

house, so no additional work has to be done except

connecting to a conditioning electronics and

calibrate.

Output Signal Voltages depend on the

applied amount of power/energy and are

expressed as mV per incident W (mV/W). The amount of successive amplification thus depends on

the overall measurement range (Min to Max value). A safe minimum measurable value, to avoid

influence of noise, has to be considered as at least 4 times the value of NEP (Noise Equivalent

Power) . Please refer to the head specs table at the end of this catalog to identify the correct value of

NEP.

As a safety rule, never let the sensor disc area face power/ energy densities (originated by a too

small size beam or hot spots) that exceed the values specified for the absorbing coating . If the

absorber is damaged, measurements may be affected and a substitution of the sensor may be

necessary (refer to Section 4 for individual threshold of each sensor).

2.2-Output Signal Condictioning

External connection options include Laser Point’s IIS (Intelligent Identification System) on DB15

connector, BNC, 4 wire pigtail.

2.2.1-The DB15 Connector –Heads with DB-15 male connectors are only provided for use with

LaserPoints readouts like the LPM, PLUS or PC-Link, either in their

laboratory or OEM versions .

LaserPoint’s Intelligent Identification System (IIS) is composed by the

DB15 connector, EEPROM and cable between the CS head and

electronics. Within the EEPROM all relevant parameter of detectors are

stored: each detector automatically identifies itself to the electronics and

supplies the stored data. The monitor is then in condition to know the

head sensitivity, the correction factors for various wavelengths or the

detector intrinsic response times, necessary to provide suitable speed-up of readings.

2.2.2- BNC connectors –They give total plug/un-plug ease and high EMI noise shielding.

Connector polarities are (+)at the central pin and (-) on the outer body. Standard BNC Connectors

are panel female, 50 Ω

2.2.3-Pigtail Output: - Heads have, as standard, a 1.5m cable terminating with bare wires for

custom links to the machine. Custom lengths can be provided on request up to 5m.

1-For any connection: the exit cable is delivered with a Yellow (+) and Brown (-), low impedance

leads. If an optional thermistor KTY 11-6 (2Kat 25°C) is internally mounted for temperature

monitoring, two extra White and Green wires are available.