4

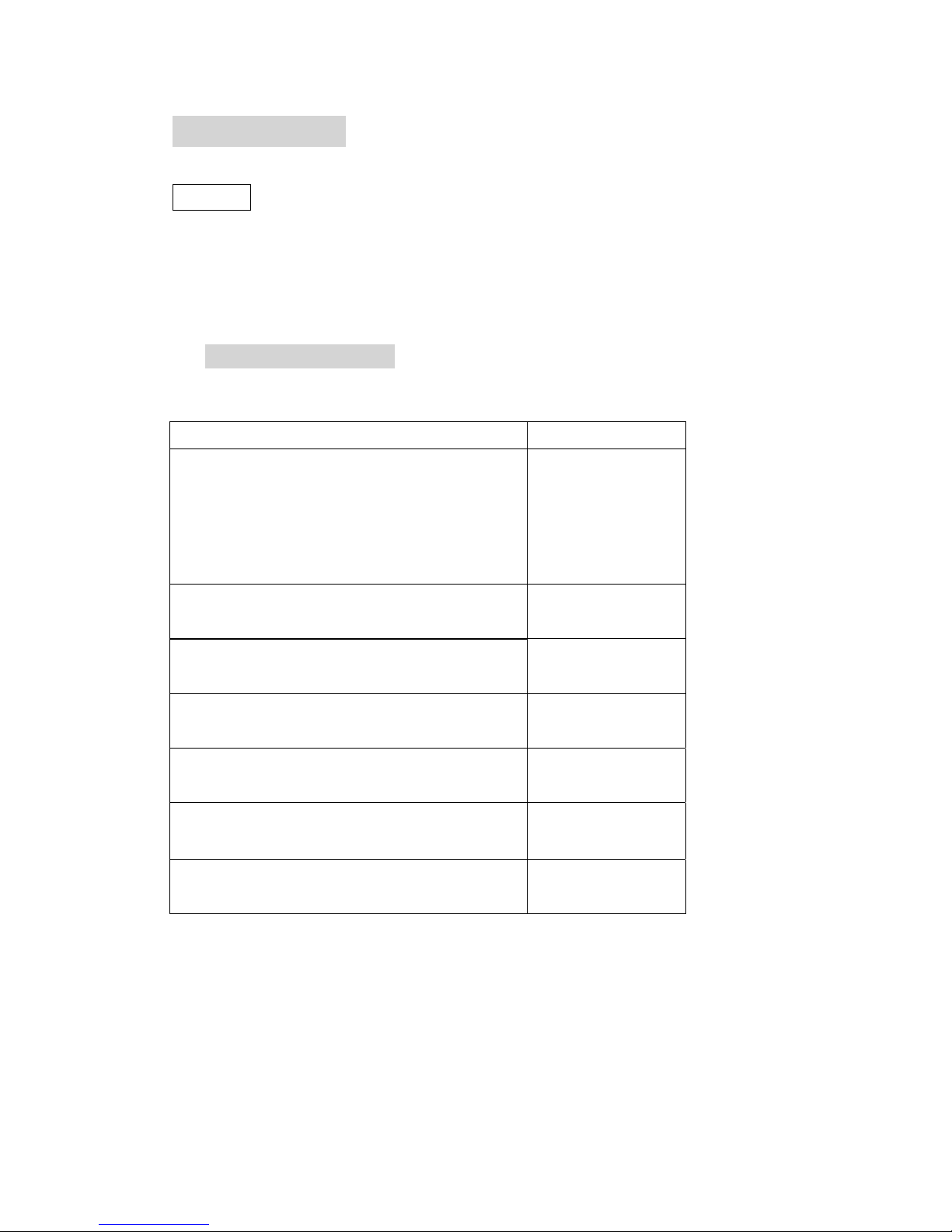

QUICK MENU

1. Connect air exhaust system.

2. Setup computer and connect with engraving system properly.

3. Turn ON host computer system.

4. Install the Venus Driver. (for the first time use only)

5. Use Windows-based program (such as CorelDRAW, PhotoShop, PhotoPaint,

Illustrator, CASmate, Signlab, EasySign, AutoCAD, etc.) to operate with the

engraver.

6. Turn ON engraver. The working table moves down 50mm approximately and

the lens carriage moves to the home position (upper left corner) after system

initialization.

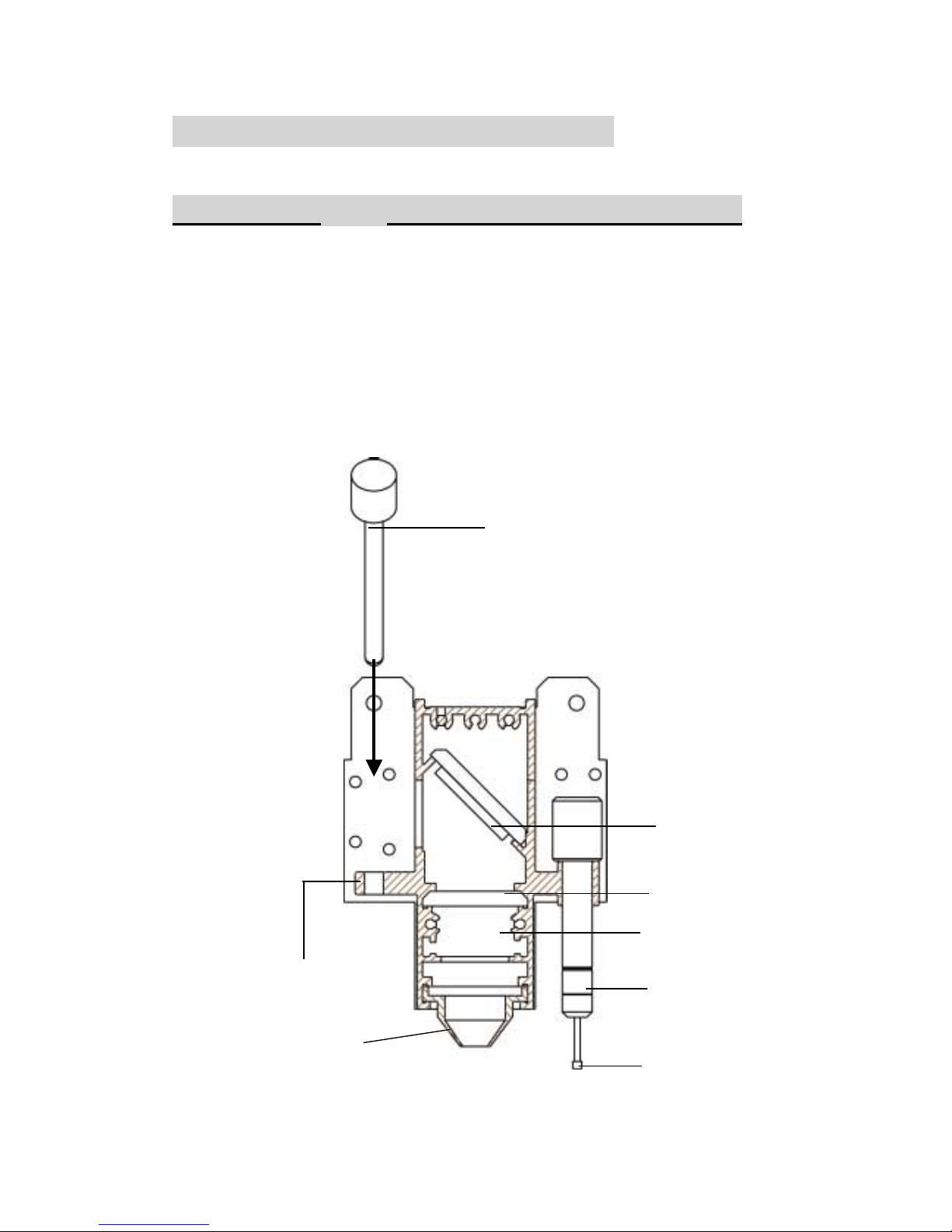

7. Auto-focusing: under STOP status, put work-piece on the table, move X-axis

(Please refer to Fig. 3) and carriage by arrow keys to locate the lens carriage

above the engraving material (holding carriage by hands for prompt moving is

acceptable under STOP condition but not recommended). Press

AUTO FOCUS the table will move up then down to the focal position

automatically.

8. The following is an example by using CorelDRAW V.7.0.

Layout Page Setup Set from Printer, choose Portrait

OK Edit desired file (picture etc.) File Print

Properties Options,choose desired Mode (refer to Fig. 8) then set

up proper resolution, power and speed OK Print

File name is shown on LCD then press START/STOP button.

(Please refer to page 14, Start to Operate, for detail operation in different

mode selection)

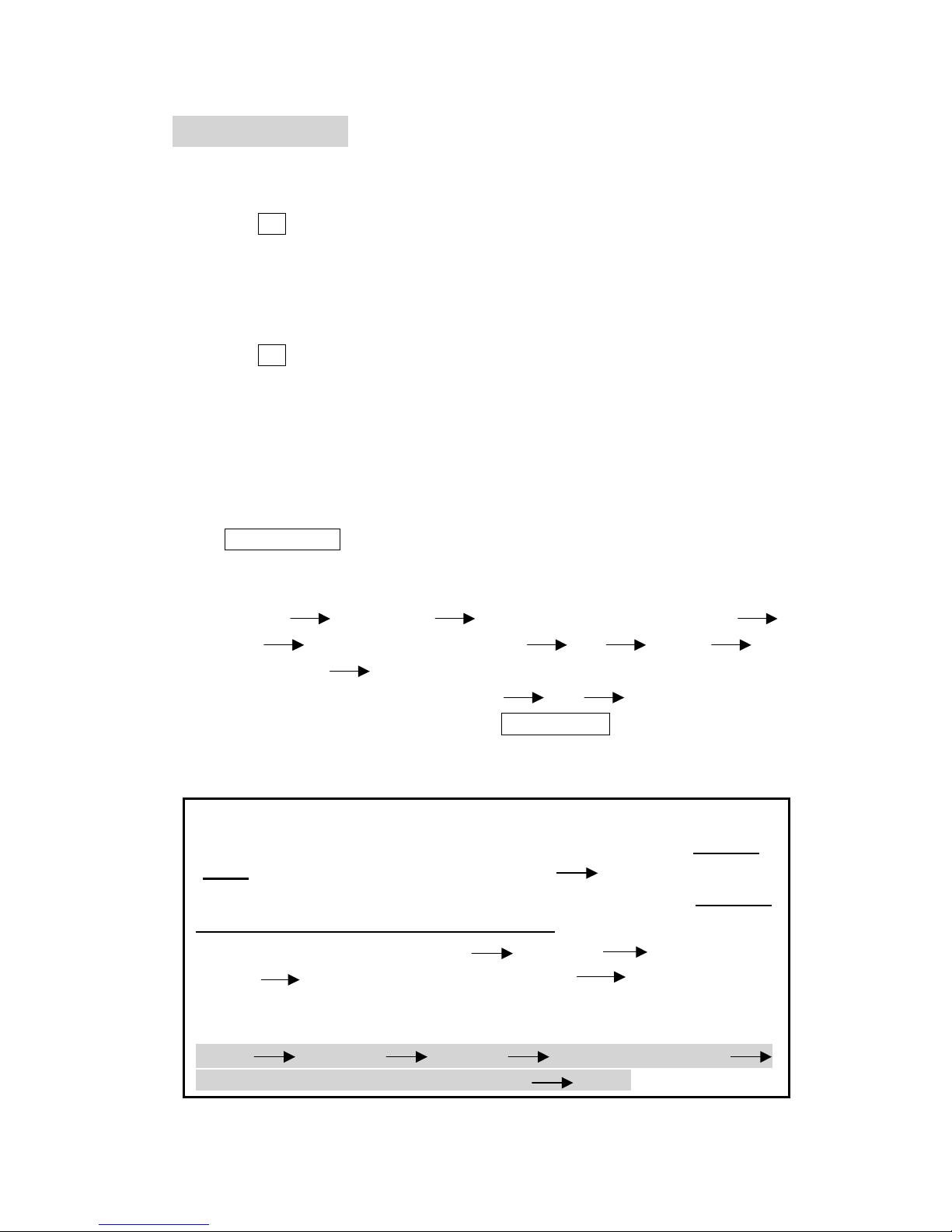

NOTICE:

1.When operating with CorelDRAW V.8.0, please choose Landscape for Page

Setup when X > Y; choose Portrait when X < YO.K..

2. When using the available artworks from the Clipart of CorelDRAW, to prevent

the hidden vector lines shown on your engravings. Please do as follows:

CorelDRAW, choose file from Clipart Bitmaps Convert to

Bitmap ClickColor then choose Grayscale Ok

3.In order to match Venus driver’s color. Make sure your CorelDRAW V.8.0 or

V.9.0 the ‘Calibrate colors for display ‘ is disable. Please follow the steps:

Tools Options Global Color Management

Disable ‘Calibrate colors for dis