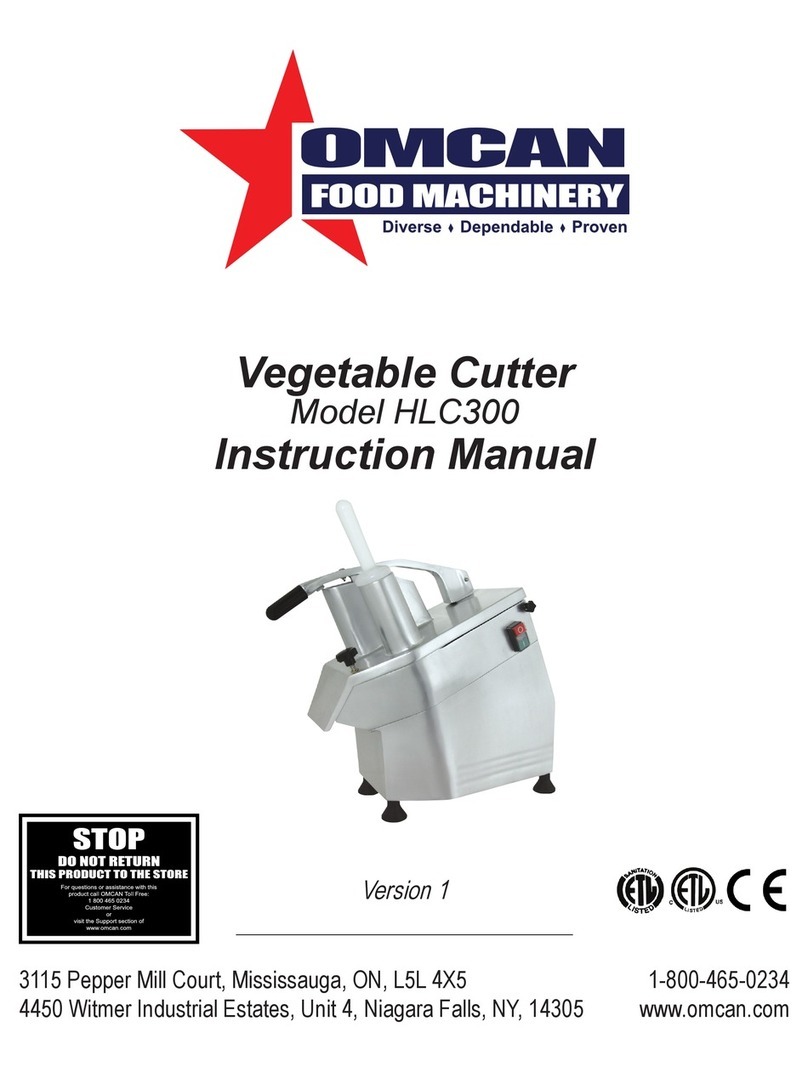

THERMACUT EX-TRACK User manual

PORTABLE CNC CUTTING SYSTEM

Operator Manual

EX-0-902-001

N-22063

Revision Date: December 01, 2019

Revision Number: 01.3

Language: English

EX-TRACK®

Operator Manual, Revision T-12

Foreword

Thank you for purchasing the Thermacut®EX-TRACK®CNC Cutting System, the system is available

with a oxy fuel cutting torch. The system has been designed and manufactured to deliver: reliability,

dimensional accuracy and reproducible profile part cutting. The system is easy to operate and

maintain, read this instruction manual before proceeding, be aware, there is a potential for danger

upon installation, operating or maintaining the system.

It is the responsibility of the operator/user to ensure the safe use/handling of the system, refer to

Thermacut’s terms and conditions of sale for specific responsibilities and limitations on liability.

Information in this document is subject to change without notice. The manual is for the convenience

and use of the Thermacut®EX-TRACK®CNC Cutting System purchaser, it is not a contract or

obligation on the part of Thermacut®“The Cutting Company”.

Safety precautions

This instruction manual describes the correct, effective and safe use of the system. All personnel

involved in the use or maintenance of the system should read this instruction manual thoroughly

and familiarize themselves in the correct and safe method of operation. A copy of this instruction

manual should be kept with the system at all times for easy reference.

EX-TRACK®

Operator Manual, Revision T-1 3

Foreword........................................................................................................................ 2

Safety precautions ........................................................................................................ 2

1. SAFETY INSTRUCTIONS ............................................................................9

1.1. General system safety precautions .................................................................. 12

1.1.1. System safety .................................................................................................... 12

1.1.2. Personal protective equipment ...................................................................... 12

1.1.3. Safety precautions prior to handling and operation ................................... 13

1.2. Plasma/oxy fuel gas cutting safety awareness................................................. 14

1.2.1. Prevention of fire and explosion..................................................................... 14

1.2.2. Safe use of gas pressure regulators .............................................................. 14

1.2.3. Gas cylinder handling and storage ............................................................... 14

1.2.4. Oxy fuel gas hose safety precautions ........................................................... 14

1.2.5. Risk of fire ......................................................................................................... 15

1.2.6. Risk of burn injury ........................................................................................... 15

1.2.7. Safety in the workplace ................................................................................... 16

2. LOCATION OF WARNING AND SAFETY LABELS .....................................18

3. SPECIFICATION .......................................................................................22

3.1. System overview.................................................................................................. 23

3.1.1. Main features .................................................................................................... 23

3.1.2. Range of application........................................................................................ 23

3.2. System parts description .................................................................................... 23

3.3. Technical parameters.......................................................................................... 24

3.4. Torch height controller........................................................................................ 24

3.5. Gas supply............................................................................................................ 25

4. UNPACKING AND ASSEMBLY..................................................................26

4.1. Packing list............................................................................................................ 27

4.2. System assembly ................................................................................................. 28

4.2.1. Parts check ........................................................................................................ 28

4.2.2. Fitting the main unit on to the longitudinal guide rail................................. 28

4.2.3. Fitting the transverse guide rail...................................................................... 29

4.2.4. Fitting the torch height controller .................................................................. 29

4.2.5. Gas supply connection.................................................................................... 30

4.2.6. Electrical connection ....................................................................................... 30

5. CUTTING PROCESS .................................................................................32

5.1. Prior to operating the system............................................................................. 33

INDEX

EX-TRACK®

Operator Manual, Revision T-14

5.1.1. Input voltage settings ...................................................................................... 33

5.1.2. EX-TRACK®placement ..................................................................................... 33

5.1.3. Oxy fuel nozzle choice..................................................................................... 33

5.1.4. Regulated gas supply ...................................................................................... 33

5.1.5. Oxy fuel cut charts............................................................................................ 33

5.1.6. Pre-ignition check............................................................................................. 34

5.2. Ignition and flame adjustment - oxy propane cutting .................................... 34

5.3. Cut quality ............................................................................................................ 35

5.4. Preheat time ......................................................................................................... 35

5.5. Torch operation.................................................................................................... 35

5.6. Flashback and backfire prevention................................................................... 36

5.6.1. Flashback prevention ..................................................................................... 36

5.6.2. Backfire prevention ......................................................................................... 36

6. SYSTEM OPERATION...............................................................................38

6.1. Oxy fuel cutting (prior to operation) ................................................................. 39

6.2. Plasma arc cutting (prior to operation)............................................................. 40

7. MAINTENANCE .......................................................................................41

7.1. Cleaning the system............................................................................................ 42

7.2. System lubrication............................................................................................... 42

7.3. Drive motor adjustment...................................................................................... 42

7.4. Oxy fuel nozzle maintenance............................................................................. 42

8. CIRCUIT DIAGRAM ..................................................................................43

8.1. Plasma interface................................................................................................... 44

9. OPERATION.............................................................................................45

9.1. Control panel functions ...................................................................................... 48

9.2. CNC system functions......................................................................................... 48

9.3. System main menu .............................................................................................. 49

9.3.1. Menu features................................................................................................... 49

9.3.2. Main function F-key menu............................................................................... 50

9.4. Automatic function.............................................................................................. 50

9.4.1. Interfaces and inputs ....................................................................................... 51

9.4.1.1. Speed ............................................................................................................. 51

9.4.1.2. Prog, pierce, kerf .......................................................................................... 51

9.4.1.3. Work mode - running status ....................................................................... 51

9.4.1.4. Input and output signals ............................................................................. 51

9.4.1.5. System parameters display ......................................................................... 51

9.4.1.6. System coordinates display ......................................................................... 52

9.4.1.7. Zoom function [key 1]................................................................................... 52

9.4.1.8. Return [key 2]................................................................................................. 52

EX-TRACK®

Operator Manual, Revision T-1 5

9.4.1.9. Dry run [X]...................................................................................................... 52

9.4.1.10. Speed [Y] ..................................................................................................... 53

9.4.2. Auto processing menu [MAIN MENU → F1 (AUTO)] .................................. 53

9.4.2.1. Pierce point [F1 (SECTION)] ........................................................................ 53

9.4.2.2. Manual mode [F2 (MANUAL)] ..................................................................... 53

9.4.2.3. Break point [F3 (BRK)]................................................................................... 53

9.4.2.4. Graphics display [F4].................................................................................... 54

9.4.2.5. Kerf [F5].......................................................................................................... 54

9.4.2.6. More [F6]........................................................................................................ 54

9.4.2.6.1. [F1 OUTLINE] PERIMETER FUNCTION ................................................... 55

9.4.2.6.2. Rotate (re-orientation) [F3] ....................................................................... 55

9.4.2.6.2.1. Re-orientation angle processing .......................................................... 55

9.4.2.6.3. Mirror [F4]................................................................................................... 56

9.4.2.6.4. Scale [F5]..................................................................................................... 56

9.4.2.6.5. Nest [F6]...................................................................................................... 56

9.4.2.6.6. Tabbing - bridge function [F7 BREAK] .................................................... 57

9.4.2.7. Return [F7]...................................................................................................... 57

9.5. Automatic program mode.................................................................................. 57

9.5.1. Cutting speed................................................................................................... 58

9.5.2. Process start point ............................................................................................ 58

9.5.3. Active key functions when running a program............................................. 58

9.5.4. Active key functions in pause mode .............................................................. 59

9.5.5. Select program................................................................................................. 61

9.5.6. Edge start cutting............................................................................................. 61

9. 6. Manual mode...................................................................................................... 62

9.6.1. Manually controlled functions ........................................................................ 62

9.6.1.1. [↑] [↓] [←] [→] [UP] [DOWN] [LEFT] [RIGHT] directional control keys [G]63

9.6.1.2. Mode switching [F1] ..................................................................................... 63

9.6.1.3. Step [F2] ......................................................................................................... 63

9.6.1.4. More [F3]........................................................................................................ 63

9.6.1.4.1. P-START [F3] a P-END [F4] ........................................................................ 64

9.6.1.4.2. Coordinates settings [F5].......................................................................... 64

9.6.1.4.3. Origin [F7]................................................................................................... 64

9.6.1.5. Mach-0 [F4].................................................................................................... 64

9.6.1.6. Rapid [F5]....................................................................................................... 64

9.6.1.7. Prog-0 [F6] ..................................................................................................... 64

9.6.1.8. Return [F7] ..................................................................................................... 64

9.7. Editing function ................................................................................................... 65

9.7.1 Edit function ...................................................................................................... 65

9.7.1.1. New [F1] ......................................................................................................... 65

9.7.1.2. Load [F2] ........................................................................................................ 65

9.7.1.3. Save [F3] ........................................................................................................ 66

9.7.1.4. Delete files [F4] ............................................................................................. 66

EX-TRACK®

Operator Manual, Revision T-16

9.7.1.5. Delete line [F5] .............................................................................................. 66

9.7.1.6. USB [F6].......................................................................................................... 66

9.7.1.7. View [F7]......................................................................................................... 66

9.8. Setup [F4 PARAMER] .......................................................................................... 66

9.8.1. Process definition - speed............................................................................... 66

9.8.2. Speed parameters [F1].................................................................................... 67

9.8.3. System parameters .......................................................................................... 68

9.8.4. OXY parameters ............................................................................................... 69

9.9. Plasma parameters.............................................................................................. 70

9.9.1. Control parameters ......................................................................................... 71

9.9.2. THC .................................................................................................................... 73

9.9.3. Save [F7]............................................................................................................ 74

9.9.4. Gallery function ................................................................................................ 74

9.9.5. Graphics library ................................................................................................ 74

9.9.6. Graphics library (shape development).......................................................... 75

9.9.7. Shape check...................................................................................................... 75

9.9.7.1. Inside diameter cut [F1] and [F2] Outside diameter cut.......................... 75

9.9.8. Graphics library (nest function) ...................................................................... 76

9.10. Program function............................................................................................... 76

9.10.1. CNC program symbols (G - codes).............................................................. 76

9.10.2. File types ......................................................................................................... 77

9.10.3. File names....................................................................................................... 77

9.10.4. Units of measurement ................................................................................... 77

9.10.5. Programming ................................................................................................. 77

9.10.6. System axes .................................................................................................... 77

9.10.7. G-codes .......................................................................................................... 78

9.10.8. G92 – program zero point............................................................................. 78

9.10.9. G90 – absolute commands ........................................................................... 78

9.10.10. G91 – incremental commands .................................................................. 78

9.10.11. G20 – imperial mode .................................................................................. 78

9.10.12. G21 – metric mode ...................................................................................... 78

9.10.13. G00 – rapid travel......................................................................................... 79

9.10.14. G01 – linear interpolation (motion in a straight line) .............................. 79

9.10.15. G02- G03 – circular interpolation (motion along a circular arc)............. 79

9.10.16. G04 – pause/dwell ....................................................................................... 79

9.10.17. G40 – kerf off (compensation factor)......................................................... 79

9.10.18. G41 – kerf left ............................................................................................... 80

9.10.19. G42 – kerf right............................................................................................. 80

9.10.20. G28 – return to reference point (zero position)........................................ 80

9.10.21. G22 / G80 – cycle command (loop function) ........................................... 80

9.11. M - codes............................................................................................................ 80

9.11.1. M00 - stop....................................................................................................... 80

9.11.2. M02 – program end ...................................................................................... 80

EX-TRACK®

Operator Manual, Revision T-1 7

9.11.3. M07 – cutting sequence start ....................................................................... 80

9.11.4. M08 – cutting sequence stop ....................................................................... 81

9.11.5. Additional M-codes ....................................................................................... 81

10. FAQ’s Operating the system .................................................................82

10.1. FAQ’s Operating the system............................................................................ 83

10.2. Basic trouble shooting...................................................................................... 85

10.3. Software service instructions - Boot menu..................................................... 92

10.4. Backup and restore parameters...................................................................... 93

10.5. Changing System name text............................................................................ 95

10.6. Hardware service instructions.......................................................................... 95

10.6.1. Replacing main fuse ...................................................................................... 95

11. Warranty terms and conditions.............................................................97

S Mark; ......................................................................................................................... 98

CE Mark;....................................................................................................................... 98

C-Tick Mark;................................................................................................................. 98

12. Certification and compliance symbols..................................................98

Appendix: Graphics library .........................................................................99

Shape 1 ......................................................................................................................101

Shape 2 ......................................................................................................................101

Shape 3 ......................................................................................................................101

Shape 4 ......................................................................................................................102

Shape 5 ......................................................................................................................102

Shape 6 ......................................................................................................................102

Shape 7 ......................................................................................................................103

Shape 8 ......................................................................................................................103

Shape 9 ......................................................................................................................103

Shape 10....................................................................................................................104

Shape 11....................................................................................................................104

Shape 12....................................................................................................................104

Shape 13....................................................................................................................105

Shape 14....................................................................................................................105

Shape 15....................................................................................................................105

Shape 16....................................................................................................................106

Shape 17....................................................................................................................106

Shape 18....................................................................................................................106

Shape 19....................................................................................................................107

Shape 20....................................................................................................................107

Shape 21....................................................................................................................107

Shape 22....................................................................................................................108

EX-TRACK®

Operator Manual, Revision T-18

Shape 23....................................................................................................................108

Shape 24....................................................................................................................108

Shape 25....................................................................................................................109

Shape 26....................................................................................................................109

Shape 27....................................................................................................................109

Shape 28....................................................................................................................110

Shape 29....................................................................................................................110

Shape 30....................................................................................................................110

Shape 31....................................................................................................................111

Shape 32....................................................................................................................111

Shape 33....................................................................................................................111

Shape 34....................................................................................................................112

Shape 35....................................................................................................................112

Shape 36....................................................................................................................112

Shape 37....................................................................................................................113

Shape 38....................................................................................................................113

Shape 39....................................................................................................................113

Shape 40....................................................................................................................114

Shape 41....................................................................................................................114

Shape 42....................................................................................................................114

Shape 43....................................................................................................................115

Shape 44....................................................................................................................115

Shape 45....................................................................................................................115

Shape 46....................................................................................................................116

Shape 47....................................................................................................................116

Shape 48....................................................................................................................116

Shape 49....................................................................................................................117

Shape 50....................................................................................................................117

Notes:.........................................................................................................................118

Revision history: ........................................................................................................119

EX-TRACK®

Operator Manual, Revision T-1 9

SECTION 1.

SAFETY INSTRUCTIONS:

1.1. General system safety precautions ............................................................................... 12

1.1.1. System safety ................................................................................................................. 12

1.1.2. Personal protective equipment ................................................................................... 12

1.1.3. Safety precautions prior to handling and operation ................................................ 13

1.2. Plasma/oxy fuel gas cutting safety awareness.............................................................. 14

1.2.1. Prevention of fire and explosion.................................................................................. 14

1.2.2. Safe use of gas pressure regulators ........................................................................... 14

1.2.3. Gas cylinder handling and storage ............................................................................ 14

1.2.4. Oxy fuel gas hose safety precautions ........................................................................ 14

1.2.5. Risk of fire ...................................................................................................................... 15

1.2.6. Risk of burn injury ........................................................................................................ 15

1.2.7. Safety in the workplace ................................................................................................ 16

1. SAFETY INSTRUCTIONS

EX-TRACK®

Operator Manual, Revision T-110

Safety Instructions

Many accidents are caused by disregard for basic safety rules in the operation, inspection and

maintenance of devices. So carefully read, fully understand, and comply with the safety measures

and precautions described in this instruction manual and on the system before operating,

inspecting, and maintaining the system.

The system safety label categories are as follows:

WARNING

CAUTION

NOTICE SIGNS

This symbol is used as a warning message or a warning label. It is positioned at

places that could cause injury or serious accident.

This symbol is used as a caution message or a caution label. It is positioned at places

that could cause slight injury or system damage. This is also used as a caution for

highly dangerous actions.

This symbol shows system operators and maintenance engineers items that relate

directly to damage of systems and surrounding facilities and equipment.

EX-TRACK®

Operator Manual, Revision T-1 11

Warning symbols

Symbol Title Meaning

General General caution, warning and danger.

Be careful not to get your

fingers caught!

Possible injury to fingers if caught in the insertion

part.

Caution: Electric shock! Possible electric shock under special conditions.

Ground this equipment. Operators must ground the equipment using the

safety grounding terminal on power plug.

Pull out the power plug from

the outlet.

Operators must unplug the power plug from the

outlet when a failure occurs or when there is a

danger of lightning and when performing all

maintenance tasks.

Caution against bursting. Possible bursting of gas system under certain

conditions.

General General warning.

Caution: Hot! Possible injury due to high temperature under

certain conditions.

Caution: Ignition! Possible ignition under certain conditions.

EX-TRACK®

Operator Manual, Revision T-112

1.1. General system safety precautions

1.1.1. System safety

The EX-TRACK®CNC System is fitted with an Emergency Stop or E-Stop Button. This button is used

to isolate the system from the input (120V/220V) power source. It is intended for use in the case

of an accident or emergency. The E-Stop Button is clearly located on the top of the Main Unit, to

operate, press in to isolate the power to the CNC and drive mechanisms, none of the systems

functions can operate. To restore power to the system, lift the E-Stop Button upwards, the screen will

illuminate and all of the systems functions are restored.

1. The system casing is made from cast Aluminium and sheet metal, exercise care when

handling, do not let the system drop from any height, and protect the system from falling

objects.

2. Oxygen and fuel gas fittings and connections should be tightened using a suitable wrench,

perform a leak test and retighten as required.

3. When fixing a nozzle to the oxy fuel torch, tighten the nut with two wrenches. In addition,

avoid; damaging the seat of the nozzle since this may cause flashback.

4. Never disassemble the system other than during maintenance and inspection. Otherwise,

a system malfunction may occur.

5. Never modify the system. Modification can be very dangerous and voids the warranty.

6. Switch the power off when the system is not in use.

7. Never use the system outside in the rain, the system may malfunction, this could result

in serious injury or death.

8. This system is not intended for use with plasma cutting power supplies that utilize high-

frequency (H/F) arc ignition.

1.1.2. Personal protective equipment

1. During operation, ensure that suitable personal protective equipment is used: gloves,

gauntlets, goggles, face shields, safety shoes, and additional equipment as required.

2. Prohibit operation of the system if clothes or hands are wet, in order to prevent electric shock,

electric shock can cause serious injury or death.

EX-TRACK®

Operator Manual, Revision T-1 13

1.1.3. Safety precautions prior to handling and operation

1. Read and understand the content of this instruction manual before operating the system.

2. Before connecting the external power supply to the system, ensure that the system ON/OFF

switch is set to OFF.

3. Before operating, check to confirm correct installation, ensure that the movement of the

mechanism is unrestricted.

4. Prior to operating the system, check the work area for hazards in order to avoid accidents

5. Never move or reposition the system when in use, there is a serious risk of injury from Oxy

fuel flame and plasma arc stream.

6. Keep the rail clean and free from debris, failure to do so can result in damage to the system,

and the machine-guiding track, thus affecting the cut quality.

7. Care should be taken to prevent objects impacting/colliding with the track.

8. Prior to powering up the system, ensure that the OFF Line button is depressed (OFF position).

When the system ON/OFF switch is in the ON position, the OFF Line button should NOT be

illuminated. Failure to do so can result in injury.

9. To reduce the risk of an accident, prohibit the touching of moving parts while the system is

running.

10.DO NOT use the EX-TRACK®for welding purposes the circuit boards will suffer catastrophic

damage!

11.Do not operate the system during an earthquake.

12.Ensure correct connection of the oxygen and fuel gas hoses. Gas fittings/connections are

screw threaded; ensure they are correctly tightened to prevent them becoming loose during

operation.

13.If running the system in oxy fuel mode: when checking the running of system (dry run), ensure

that the preheat oxygen valve and the fuel gas valve are in the OFF position.

14.After cutting, the cutting nozzle, torch and mountings may be hot, wear gloves if handling

these parts.

15.Prevent the power cable and hoses from being trapped or crushed, ensure their free

movement.

16.The EX-TRACK®system is not designed for use where it is mounted on soft ground or

unstable surfaces.

17.Do not leave the system unattended when in use.

18.Hoses should be supported to reduce the risk of accidents/injury.

19.When a fuse frequently blows, to prevent damage to the system or injury to the operator, stop

all use, the cause for the fuse failure requires investigation/repair before commencing work

with the system.

EX-TRACK®

Operator Manual, Revision T-114

1.2. Plasma/oxy fuel gas cutting safety awareness

It is essential that ALL operators of the system are aware of the potential danger/risk associated with

Plasma/Oxy fuel Gas cutting operations. Keep “SAFETY” in mind!

1.2.1. Prevention of fire and explosion

1. Never cut in to pressurized cylinders or hermetically sealed containers. Check for flammable

liquids, gases, vapors and other combustible materials.

2. Ensure there is sufficient ventilation to safely use Oxy fuel gas or plasma cutting processes,

use fume extraction/forced air systems as required.

1.2.2. Safe use of gas pressure regulators

1. Prior to use, perform a visual check on the regulators, look for physical damage to the body/

gauges, check for a sticking pressure indicator, ensure the gauges are clean and dry.

Do not allow pressure regulators to come in to contact with oil or grease, this can lead

to spontaneous combustion.

2. Gradually open the cylinder/manifold valve (manifolds are used on multi-gas delivery

systems) allowing the regulator to be pressurized without causing a sudden violent shock that

can cause damage.

3. Check the pressure gauge dial to ensure the pressure indicator is not sticking, listen for gas

leaks. Do not use damaged or leaking pressure regulators.

4. Do not attempt the repair of pressure regulators. Specialist training and equipment is

required. Serious injury or death can result from tampering with the device.

1.2.3. Gas cylinder handling and storage

1. Never use cylinders that are damaged, have been used as rollers/supports or are leaking gas.

2. Cylinders should be stored/installed away from sources of heat, sparks, molten metal, and

open flame. Kept in an upright position, take measures to prevent them from falling, secure

using chains or other approved methods.

3. Cylinders are to be used for the specified purpose only.

4. Contact the cylinder supplier if there is difficulty in opening/closing the valve. Do not use

force.

1.2.4. Oxy fuel gas hose safety precautions

1. The hoses are color coded, RED for fuel gas and Blue for oxygen, the hose fittings have

dissimilar threads, the fittings on the fuel gas (RED) hose are “Left hand or Anti-clockwise”

threads, the fittings have a small groove machined in to the external surface as an

identification mark. The fittings on the oxygen (BLUE) hose are “Right hand or Clockwise”

threads.

EX-TRACK®

Operator Manual, Revision T-1 15

2. Replace hoses that are showing signs of cracking, leaking, and damage caused by sparks,

heat, open flame, crushed etc.

3. When installing hoses, do not over tighten the fitting.

4. Exercise care when using/transporting hoses.

5. Do not drag the hoses when moving the system.

6. Perform Periodic safety checks to confirm the condition of the hoses, as a minimum the hoses

should be free from signs of damage, age related wear/cracking with no gas leaks from the

hoses or fittings.

7. Where possible use the minimum length of hose between the gas supply point and the

EX-TRACK®, this reduces the risk of excess hose being damaged or causing a trip hazard. A

shorter hose may improve gas flow.

1.2.5. Risk of fire

Prior to cutting, survey the work area and assess the risk of fire. The cutting processes

generate as a minimum hot molten metal and sparks. You are responsible for your own safety

as well as others.

1. The work area should be free from flammable liquids, gases, vapors and other combustible/

flammable materials, ensure that suitable fire extinguishers for use on: Gas/Electrical/Hot

metal fires are suitably located, locate fire buckets with sand/water as necessary.

2. Allow the parent material, profile cut parts and scrap time to cool down before moving them.

3. Never cut in to sealed or open canisters/containers that have been used for gases or

flammable products.

1.2.6. Risk of burn injury

Observe the safety precautions to avoid the risk of a burn injury. The oxy fuel and plasma

cutting processes generate as a minimum hot molten metal, sparks and radiation, the effects

can occur both during and after the cutting process.

1. Do not cut near flammable liquids, gases, vapors or other combustible/flammable materials.

Remove flammable materials from the work area, flying sparks are a source of ignition

2. Never cut into sealed or open canisters/containers that have been used for gases or

flammable products.

3. Do not keep lighters or matches on your person.

4. When operating the EX-TRACK®system, maintain a safe distance from the torch.

5. To minimize the risk of injury, the appropriate Personal Protective Equipment must be worn.

EX-TRACK®

Operator Manual, Revision T-116

6. Oxy fuel cutting, ensure that the nozzle is correctly seated and tightened so as not to damage

the seat/sealing area and prevent “Flashbacks” to the system.

• Whenxinganozzletothetorch,usetwowrenchestoavoiddamagetothetorch.

Over tightening the nozzle will result in the nozzle overheating during the cutting

process, making the nozzle more difficult to remove.

• Damagetothetaperofthenozzlecancause“Flashbacks”.

7. An appropriate method of gas leak detection should be used to check the torch, hoses,

connectors, vales and regulators, a suitable “Flashback Arrestor” should be fitted to reduce

the risk of fire or explosion.

DANGER! DO NOT use oil or grease products on the Oxygen hose/torch/valve/regulator or

connections, spontaneous combustion can cause a fire and lead to an explosion. To prevent

any risk of cross contamination, it is advisable NOT to permit the use of oil or grease on any

of the Oxy fuel supply or delivery components.

8. Check the following prior to igniting the Oxy fuel torch: Ensure that the torch is correctly

seated and fixed in to the torch mount. The appropriate Personal Protective Equipment is to

be worn/used. Check the work area for obstacles, hazardous/flammable materials. Check that

the input and output gas pressures are correct and suitable for the job in hand

9. Appropriate Personal Protective Equipment is to be worn/used when handling the torch,

nozzle, idler wheel locking device, allow adequate time for the system to cool down after

cutting.

1.2.7. Safety in the workplace

1. Use of the cutting processes will produce but not be limited to the following: Sparks, molten

metal, high temperatures, thermal radiation, combustible gases, dust, noise, electric arc light,

electromagnetic radiation. Serious injury can arise from failure to wear/use the appropriate

Personal Protective Equipment during the cutting process. Flammable/highly combustible

gasses are used in the Oxy fuel cutting process, exercise caution, gas leaks or misuse of the

system could result in a fire, explosion and serious injury. Misuse of the cutting system may

cause catastrophic failure of the equipment, resulting in explosive gas leaks/electric shock/

burn injury.

2. The work area should be equipped with the most suitable fire extinguishing equipment,

ensure that the correct extinguishing process is used for fire caused by but not limited

to: gas leaks, electrical fault or hot metal, not all fire extinguishing equipment is suited to

extinguishing all fire types.

3. Implement strict adherence to the relative gas use regulations, cylinder storage, equipment

pressure/condition checks, flashback arrestor checks etc.

4. Keep the work area free from flammable/combustible material. Use of the cutting processes

will produce but not be limited to the following: Sparks, molten metal, high temperatures,

combustible gases, dust, fume extraction should be used in the work area, and this is in

addition to the operator wearing/using Personal Protective Equipment.

5. Prior to starting the cutting process, the operator is to ensure that only authorized personnel

are in the work area.

EX-TRACK®

Operator Manual, Revision T-1 17

ATTENTION: Prior to starting the cutting process, perform a system/equipment check to ensure

there are no gas leaks or visible damage to component parts. If during the cutting process there is

the odor from a gas leak, immediately press the E-Stop button to isolate the electrical power supply,

turn off the gas supply at the torch and then at the point of supply - Cylinder/Manifold. Do not use

the system until it has been checked and deemed safe to use by a suitably qualified person. You are

responsible for your own safety as well as others.

EX-TRACK®

Operator Manual, Revision T-118

2. LOCATION OF WARNING AND SAFETY

LABELS

SECTION 2.

LOCATION OF WARNING AND SAFETY LABELS:

Warning and Safety labels have been affixed to the system for the purpose of hazard awareness

and correct use of the system. Prior to operating the system carefully read the labels and follow the

instructions. Do not remove labels. Always keep the labels legible.

! Caution!

Plasma arc rays can burn eyes and skin

Noise can damage hearing

Flying sparks (arc spray) can cause injury, fire or explosion

Caution! Read operator´s manual

Cutting can cause fire or explosion

Electric shock can kill

Plasma arc can injure

Flying sparks (arc spray) can cause injury, fire or explosion

Hot parts can cause severe burns

Smoke and gases can be hazardous

Caution when cutting around gas cylinders

Do not exceed the recommended duty cycle, this can lead to overheating and cause damage to the system

Magnetic field can affect pacemakers

Plasma cutting can cause interference

Safety sticker

EX-TRACK®

Operator manual, Revision T-1 19

SAFETY

The symbol shown in this section means: !Caution! !Beware!

¡There are possible hazards with this procedure!

When you find this symbol in the manual or on the system,

be cautious, and follow the related instructions to avoid the

hazard.

Follow the safety instructions to avoid danger.

Only qualified persons should install, operate, maintain and

repair the system.

Keep out of reach of children.

Prolonged exposure to noise from plasma cutting/gouging

can cause hearing damage.

• Use approved ear protection when operating the

plasma system.

• Warn others about the dangers of noise.

NOISE CAN DAMAGE HEARING

!Caution!

Arc rays from the cutting/gouging processes produce intense

visible and invisible rays that can burn eyes and skin.

Use protective clothing made from durable, flame-resistant

material, appropriate footwear and hand protection.

• Use face protection (welding helmet or shield) with

the correct shade of filter lens fitted to protect your

eyes and face (see Table 1.1).

• Warn people of the dangers of looking at the arc, use

signs to warn/inform.

PLASMA ARC RAYS CAN BURN EYES AND SKIN

Flying sparks are created during the metal cutting/gouging

processes; the area around the cutting process should be kept

free from flammables.

• Use face shield/safety glasses with side protection.

• Wear flame resistant clothing, footwear and hand

protection.

• Use earplugs/defenders that are flame resistant to

prevent sparks entering the ear and to reduce the

noise level.

FLYING SPARKS (ARC SPRAY) CAN CAUSE INJURY, FIRE OR

EXPLOSION

1

2

Caution!

Readoperator’smanual

EX-TRACK®

Operator Manual, Revision T-120

Touching electrical parts could cause a fatal shock or severe

burns.

• Do not touch live electrical components.

• Wear dry insulated gloves, shoes and protective clothing.

• Insulate yourself from the work and ground using dry

insulating material large enough for the work area.

• The working area should be clean and dry.

• Switch OFF the system for cleaning and maintenance

operations.

• Do not wrap cables around your body.

• Turn OFF the machine when not in use.

ELECTRIC SHOCK CAN KILL

• Periodically check the power supply cable, to insure

that the outer insulation is intact. Replace the power

supply cable immediately if damaged. DO NOT use

the system with bare or exposed wires, this is highly

dangerous.

• Before removing the cover or handling any of the

internal components of the system, wait 5 (FIVE)

minutes to ensure complete discharge of the

capacitors.

• Keep the system in good condition; repair or replace

damaged parts immediately. Maintain the system in

accordance with the manual.

FIRE PREVENTION

• Keep flammable items away from the work area.

• Ensure that there is a fully charged fire extinguisher in the

work area

• Ventilate the work area, check for flammable/combustible

gases, liquids and materials, remove prior to cutting as

they present a fire risk.

EXPLOSION PREVENTION

• Do not cut in areas containing explosives, flammable

gases or vapors.

• Do not place the system on, over, or near combustible

surfaces.

Caution! After cutting, the work piece will be HOT!

• Do not touch hot parts bare handed, wear suitable

hand protection.

• Allow cooling time before handling.

CUTTING CAN CAUSE FIRE OR

EXPLOSION

Flying sparks are created during the metal cutting/gouging

processes; the area should be kept free from flammables.

• Use face shield/safety glasses with side protection.

• Wear flame resistant clothing, footwear and hand

protection.

• Use earplugs/defenders that are flame resistant to

prevent sparks entering the ear and to reduce the

noise level.

FLYING SPARKS (ARC SPRAY)

CAN CAUSE INJURY, FIRE OR

EXPLOSION

The plasma arc is activated immediately after the torch trigger

is depressed.

• Turn off the power before changing the torch

consumables, the plasma arc can burn through skin and

gloves.

• Do not place your hand or hold the work piece near the

cutting path.

• Do not point the torch toward yourself or other persons.

PLASMA ARC CAN INJURE

3

4

5HOT PARTS CAN CAUSE

SEVERE BURNS

• Do not operate the system in areas with an

atmosphere containing high concentrations of dust,

flammable gases or vapors.

• Do not use the system to cut pressurized containers

that have not been de-pressurized, vented and

cleaned.

Table of contents

Other THERMACUT Cutter manuals