TABLE OF CONTENTS

USER WARNINGS...................................................................................................................1

RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING INSTRUMENTS.1

MAIN CHARACTERISTICS OF THE INSTRUMENTS............................................................2

BUFFER BATTERY....................................................................................................................2

TECHNICAL SPECIFICATIONS..............................................................................................3

W100, W200...............................................................................................................................3

WDESK-LIGHT...........................................................................................................................3

WDESK-L/R, WINOX-L/R/2L, WTAB-L/R .................................................................................3

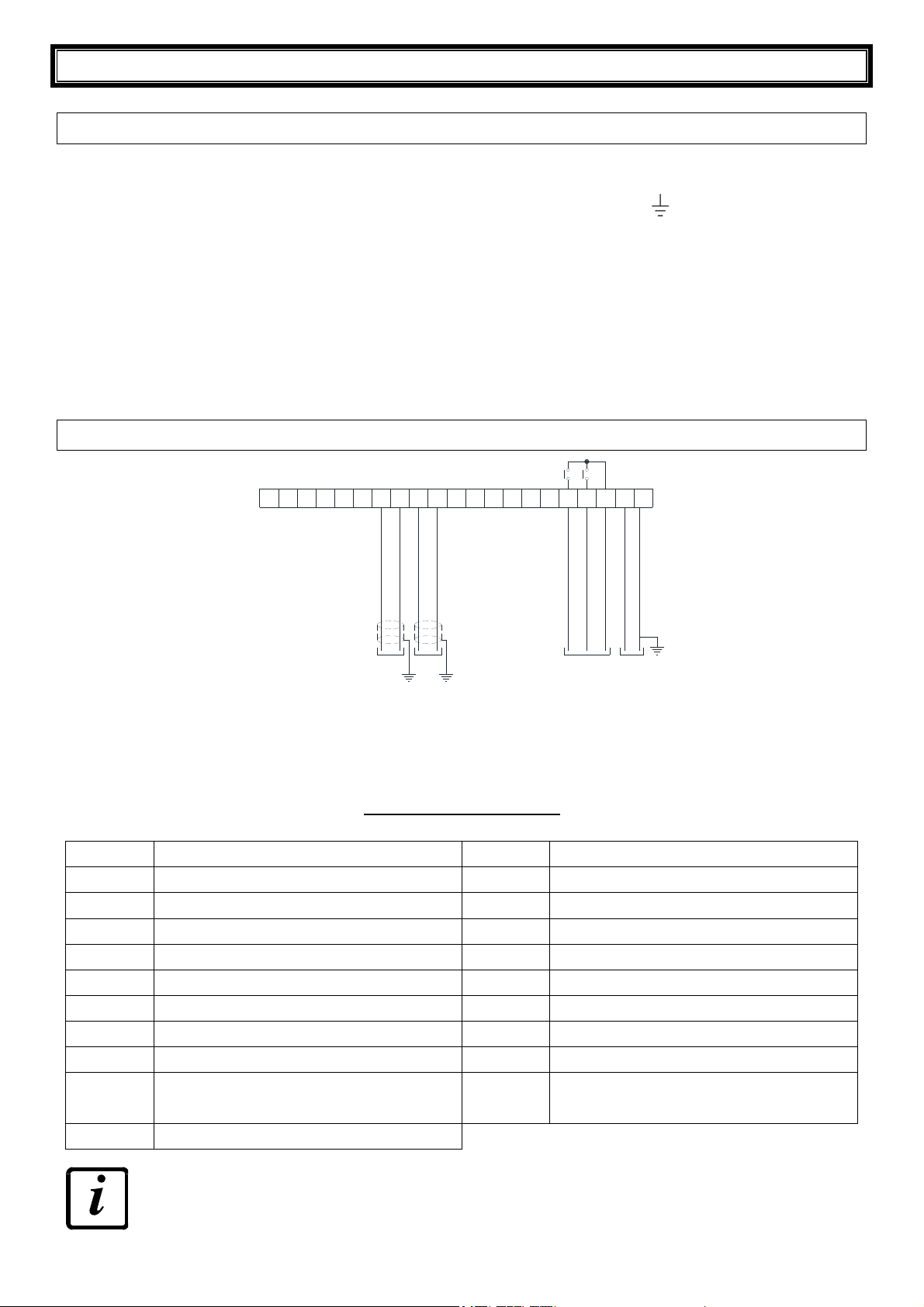

ELECTRICAL CONNECTIONS................................................................................................4

BASIC INFORMATION...............................................................................................................4

WDESK-LIGHT...........................................................................................................................4

TERMINALS LEGEND........................................................................................................................4

W100 – W200.............................................................................................................................5

CHANGING VOLTAGE 115 VAC/230 VAC (W200)...........................................................................6

TERMINALS LEGEND........................................................................................................................6

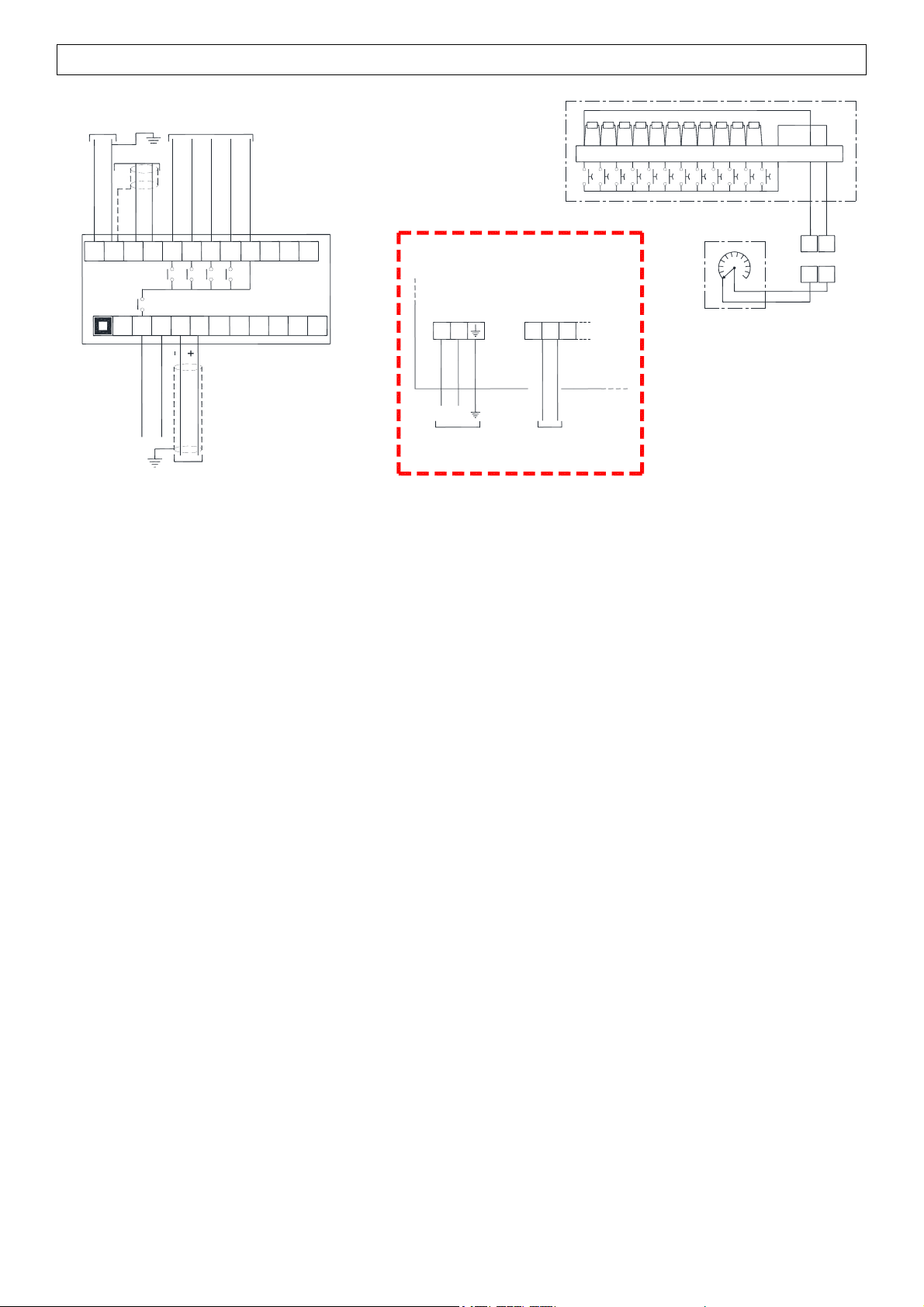

WDESK-L/R – WINOX-L/R/2L – WTAB-L/R .............................................................................7

CHANGING VOLTAGE 115 VAC/230 VAC (WDESK-L/R) ...............................................................7

INSTRUMENTS BACK TYPES...........................................................................................................8

KEY TO P, Q, X TYPE CONNECTORS..............................................................................................8

KEY TO D TYPE CONNECTORS.......................................................................................................9

RS485 SERIAL COMMUNICATION ........................................................................................10

RS232 SERIAL COMMUNICATION ........................................................................................10

LED, SYMBOLS AND KEY FUNCTIONS..............................................................................11

MENU MAP ............................................................................................................................12

SETPOINT................................................................................................................................12

SYSTEM PARAMETERS.........................................................................................................12

PROGRAMMING OF SYSTEM PARAMETERS....................................................................13

SERIAL COMMUNICATION SETTINGS .................................................................................13

SETTING THE NUMBER OF DECIMALS................................................................................13

SETTING UNIT OF MEASURE................................................................................................13

SELECTION OF THE WEIGHT TYPE TO DISPLAY...............................................................14

OUTPUTS AND INPUTS CONFIGURATION ..........................................................................14

TEST.........................................................................................................................................14

DATE AND TIME SETTING.....................................................................................................14

SETPOINT PROGRAMMING.................................................................................................15

ALARMS.................................................................................................................................15

RECEIVING PROTOCOL.......................................................................................................16

RESERVED FOR THE INSTALLER......................................................................................17

MENU LOCKING......................................................................................................................17

MENU UNLOCKING.................................................................................................................17