Superabrasive UserManual OriginalLanguageLavina®20N‐X 6/2017

4

Contents

WARRANTYANDRETURNS.........................................................3

1.GENERALINFORMATION........................................................5

Machinecharacteristics..............................................................5

Maindesign................................................................................5

VacuumConnection...................................................................6

TECHNICALDATA........................................................................6

VIBRATIONS................................................................................6

2.SAFETYINSTRUCTIONS...........................................................6

RecommendedUse....................................................................6

ProhibitedUse............................................................................6

Preparationforwork..................................................................6

ProtectionDevices......................................................................7

ArrestFunctions.........................................................................7

SafeUse......................................................................................7

ResidualRisks.............................................................................7

BeforeYouBegin........................................................................7

OPERATINGMACHINE................................................................7

AFTERWORKISCOMPLETED.....................................................7

THEWORKAREA.........................................................................7

PERSONALPROTECTIVE..............................................................7

EQUIPMENT(PPE)......................................................................7

OPERATOR..................................................................................7

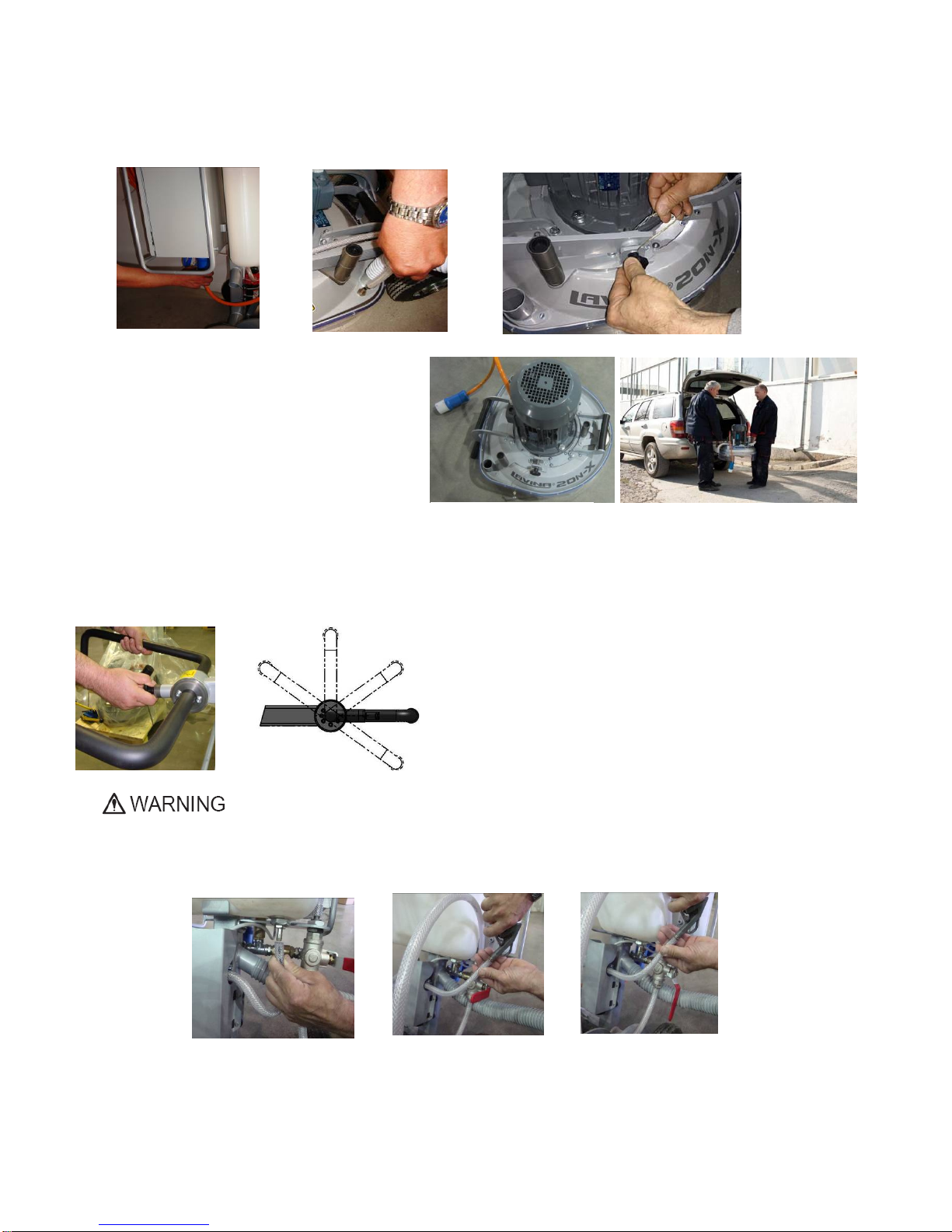

3.HANDLINGANDTRANSPORTATION........................................8

SEPERATINGTHECARRIAGEFROMTHEMAINHEAD.................8

Adjustingthehandle...................................................................8

STORAGE....................................................................................8

4.OPERATION.............................................................................9

PreliminaryControls...................................................................9

WaterFlowControlUnit.............................................................9

ADJUSTINGANDMOUNTINGTOOLS..........................................9

TheControlBoard......................................................................9

StartingtheMachine................................................................12

OperatingtheMachine.............................................................12

StoppingtheMachine..............................................................12

ALARM......................................................................................12

5.TOOLSANDACCESSORIES.....................................................13

Weights....................................................................................13

Toolholderkey.........................................................................13

FoamPlate................................................................................13

SecurityplateforQuickchangepads........................................13

6.POPULARTOOLS...................................................................14

7.MAINTENANCEANDINSPECTION.........................................15

CLEANING.................................................................................15

CHECKDAILY.............................................................................15

CHECKANDREPLACEAFTERTHEFIRST15WORKINGHOURS..15

CHECKEVERY200WORKINGHOURS........................................15

CHECKEVERY400WORKINGHOURS........................................15

VACUUM...................................................................................15

WATERLEAKS...........................................................................15

MECHANICALPARTS.................................................................15

ElectricalSystem.......................................................................16

SINGLEphaseorthreephaseconnection.................................16

Lavina®20N‐XElectrical............................................................17

schemeswithYaskawaInverter200‐240Volt..........................17

8.TROUBLESHOOTING...............................................................18

IndexofProblemsandSolutions..............................................18

8.1ReplacingPowerCordandPlugs.........................................18

8.2DISMOUNTINGTOOLHOLDERTOCHANGINGV‐RINGSANDFELT‐RINGS

..................................................................................................18

8.3DISASSEMBLINGANDMOUNTINGTOOLHOLDERTOCHANGEBUFFERSAND

ELASTICELEMENT.....................................................................18

8.4ACCESSINGTHEPLANETARYBELT.......................................20

8.5Mountingandtensioninganewplanetarybelt..................20

8.6TensioningusedplanetaryBelt...........................................21

8.7ReplacingPulleyUnits.........................................................21

8.8Mountingthebelt...............................................................23

8.9Checkingthetensionofthebelt.........................................24

8.10MotorConnection.............................................................24

8.11FaultdiagnosisInverterYASKAWAV1000.........................25

9.DISPOSAL..............................................................................27

10.MANUFACTURER’SCONTACTS............................................27

11.SPAREPARTS.......................................................................28

1.LAVINA®20N‐XGeneralParts...............................................28

2.LAVINA®20n‐XTopcoverparts1.........................................28

3.LAVINA®20n‐xGuardparts..................................................29

4.LAVINA®20N‐XtopcoverParts3.........................................29

5.LAVINA®20N‐XbottomcoverParts1...................................29

7.LAVINA®20N‐XbottomcoverParts2...................................30

6.LAVINA®20N‐XPlanetarydriveParts...................................30

8.LAVINA®20N‐XPULLEYUNITPARTS2..................................30

9.LAVINA®20N‐XToolHolderParts.........................................31

10.LAVINA®20N‐XWaterTANKParts......................................31

11.LAVINA®20N‐XCARRIAGEPARTS.......................................32

12.LAVINA®20N‐XCONTROLBOXPARTS200‐240VOLT.......33