Version 1.1.4 dated 2022-09-23Page 2 Translation of the original instructions

GH 10T | GH 15TEN

Table of contents

1 Safety

1.1 Representation Conventions ...................................................................................................................4

1.2 Safety instructions (warning notes) ..........................................................................................................4

1.2.1 Classification of hazards ..............................................................................................................4

1.2.2 Other pictograms ..........................................................................................................................5

1.3 Intended use ............................................................................................................................................5

1.4 Possible dangers caused by the drill bit grinder ......................................................................................6

1.5 Qualification of the staff ...........................................................................................................................6

1.5.1 Target group .................................................................................................................................6

1.5.2 Authorized personnel ...................................................................................................................7

1.6 Operator positions ...................................................................................................................................8

1.7 Safety measures during operation ...........................................................................................................8

1.8 Safety devices .........................................................................................................................................8

1.9 Safety check ............................................................................................................................................8

1.10 Safety during operation ............................................................................................................................9

1.11 Accident report .........................................................................................................................................9

2 Technical data

2.1 Electrical connection ..............................................................................................................................10

2.2 Speed ....................................................................................................................................................10

2.3 Grinding disc ..........................................................................................................................................10

2.4 Collect chuck seat ..................................................................................................................................10

2.5 Point angle .............................................................................................................................................10

2.6 Grinding capacity ...................................................................................................................................10

2.7 Dimensions ............................................................................................................................................10

2.8 Environmental conditions .......................................................................................................................10

2.9 Emissions ..............................................................................................................................................10

2.10 Dimension grinding discs .......................................................................................................................11

3 Assembly

3.1 Scope of delivery ...................................................................................................................................12

3.2 Storage ..................................................................................................................................................12

3.3 Installation ..............................................................................................................................................12

3.3.1 Requirements regarding the installation site ..............................................................................13

3.4 Suction ...................................................................................................................................................13

4Operation

4.1 Safety .....................................................................................................................................................14

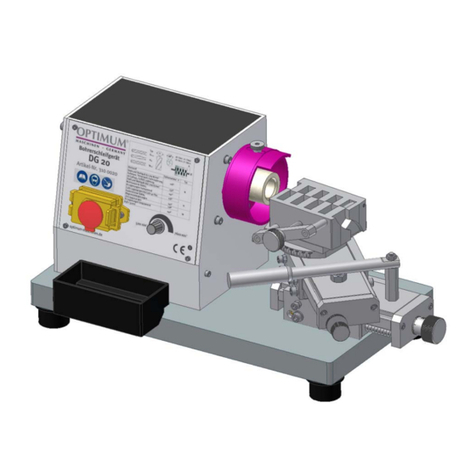

4.2 Overview ................................................................................................................................................14

4.3 Application range of coated grinding wheels .........................................................................................14

4.4 Regrinding spiral drill .............................................................................................................................15

4.4.1 Mounting clamping chuck groups ...............................................................................................15

4.4.2 Setting the spiral drill ..................................................................................................................17

4.5 Additional types of grinding on the twist drill ..........................................................................................20

4.5.1 Creating Form A .........................................................................................................................21

4.6 Drill geometry .........................................................................................................................................22

5 Malfunctions

6 Maintenance

6.1 Safety .....................................................................................................................................................25

6.1.1 Preparation .................................................................................................................................25

6.1.2 Restarting ...................................................................................................................................25

6.2 Inspection and maintenance ..................................................................................................................25

6.3 Repairs ..................................................................................................................................................25

6.4 Replacing of the grinding disc ................................................................................................................26

6.5 Fuse exchange ......................................................................................................................................27

7 Annex

7.1 Copyright ...............................................................................................................................................28

7.2 Terminology/Glossary ............................................................................................................................28

7.3 Change information manual ...................................................................................................................28

7.4 Liability claims for defects / warranty .....................................................................................................29

7.5 Advice for disposal / Options of re-use ..................................................................................................29

7.5.1 Decommissioning .......................................................................................................................30

7.5.2 Disposal of the packaging of the new machine ..........................................................................30

7.5.3 Disposal of the used machine ....................................................................................................30

7.5.4 Disposal of electrical and electronic components ......................................................................30

7.6 Disposal via municipal collecting points .................................................................................................31

7.7 RoHS, 2011/65/EU ................................................................................................................................31

7.8 Product follow-up ...................................................................................................................................31

7.9 Ersatzteilzeichnungen - Spare part drawings ........................................................................................33

7.9.1 GH15T - Ersatzteilliste - Spare part list ......................................................................................34

7.9.2 GH10T - Ersatzteilliste - Spare part list ......................................................................................37

7.10 Schaltplan - Wiring diagram - GH10T , GH15T .....................................................................................38

7.10.1 Ersatzteilliste Schaltplan - Wiring diagram parts list ...................................................................38