LavorPro TEKNA Series User manual

TEKNA MAXIMA HYPER T

IT

EN

FR

DE

ES

FI

NL

RU

EL

HR

(IT) ATTENZIONE: LEGGERE LE ISTRUZIONI PRIMA DELL’ UTILIZZO.

(EN) WARNING: READ THE INSTRUCTIONS CAREFULLY BEFORE USE.

(FR) ATTENTION: LIRE ATTENTIVEMENT LES ISTRUCTIONS AVANT L’USAGE.

(DE) ACHTUNG: DIE ANWEISUNGEN BITTE VOR GEBRAUCH SORGFÄLTIG LESEN.

(ES) ADVERTENCIA: LEER ATENTAMENTE LAS ADVERTENCIAS ANTES EL USO DE APARADO.

(NL) LET OP: VÓÓR GEBRUIK DE GEBRUIKSAANWIJZING AANDACHTIG LEZEN.

(EL) ΠΡΟΣΟΧΗ: ΔΙΑΒΑΣΤΕ ΤΙΣ ΟΔΗΓΙΕΣ ΠΡΙΝ ΤΗ ΧΡΗΣΗ.

(PT) ATENÇÃO: LER ATENTAMENTE AS INTRUÇÕES ANTES DA UTILIZAÇÃO.

(FI) HUOMIO: LUE OHJEET ENNEN KÄYTTÖÄ.

(RU) ВНИМАНИЕ: ПЕРЕД ИСПОЛЬЗОВАНИЕМ ПРОЧИТАЙТЕ ИНСТРУКЦИЮ ПО ЭКСПЛУАТАЦИИ.

(HR) PAŽNJA: PRIJE UPOTREBE PROČITAJTE UPUTE.

(SL) POZOR: PRED UPORABO PREBERITE NAVODILA.

PT

SL

TARGHETTA DATI TECNICI

Controllare che i dati tecnici riportati sulla targhetta siano corrispondenti con quelli della rete

elettrica e idrica a cui si vuole collegare la macchina.

TECHNICAL DATA PLATE

Check if the technical data on the plate correspond to those of the electricity-and waternet,

to which the machine has to be connected.

PLAQUE DONNÉES TECHNIQUES

Contrôler que les données techniques reportées sur la plaque correspondent à celles des

réseaux électriques et hydriques auxquels la machine sera branchée.

FABRIKSCHILD MIT TECHNISCHEN DATEN

Die auf dem Fabrikschild angegebenen Daten müssen mit der anliegenden Netzspannung

und Wasserleitung übereinstimmen.

PLACA DATOS TECNICOS

Controlar que los datos técnicos indicados en la placa correspondan con los de la red

eléctrica e hidraulica a las cuales se desea conectar la màquina.

TECHNISCHE GEGEVENS PLAATJE

Controleer of the technische gegevens op de plaatje corresponderen met die van het

electriciteits-en waterleidingnet waaraan de machine wordt gekoppeld.

ΠΛΑΚΕΤΑ ΤΕΧΝΙΚΩΝ ∆Ε∆ΟΜΕΝΩΝ

Ελέγχετε ότι τα τεχνικά δεδομένα που αναφέρονται στη πλακέτα αντιστοιχούν με εκείναι του

ηλεκτρικού και υδατικού δικτύου στο οποίο θέλετε να συνδέσετε τη μηχανή.

PLAQUETA DADOS TÉCNICOS

Controle que os dados técnicos indicados ne plaqueta correspondam com aqueles da rede

eléctrica e hídrica onde se dereja ligar a máquina.

TEKNISET TIEDOT SISÄLTÄVÄ KILPI

Tarkasta, että kilvessä olevat tekniset tiedot vastaavat verkkojännitettä ja vesijohtoverkostoa,

johon laite halutaan kytkeä.

ТАБЛИЧКА С ТЕХНИЧЕСКИМИ ДАННЫМИ

Проверить, чтобы технические данные, приведенные на табличке соответствовали

электрической и гидравлической сети, к которой будет подсоединяться машина.

TABLICA SA TEHNIČKIM PODACIMA

Kontrolirajte da li se tehnički podaci navedeni na tabli sa podacima podudaraju s onima

električne i vodovodne mreže na koju se želi obaviti povezivanje mašine.

TABLICA S TEHNIČNIMI PODATKI

Preverite, da so na tablici navedeni tehnični podatki skladni s podatki električnega in

vodovodnega omrežja, na kateri nameravate stroj priključiti.

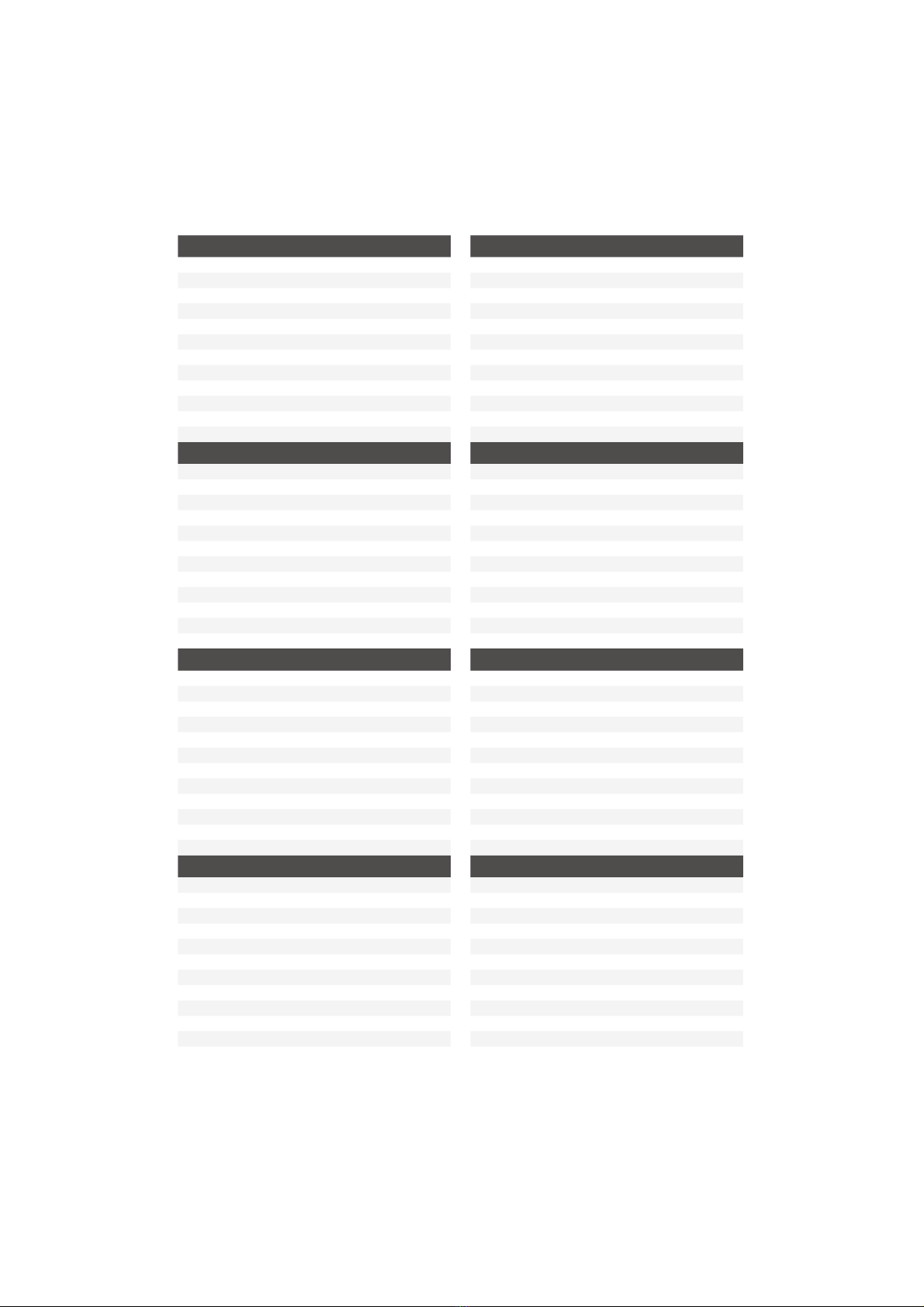

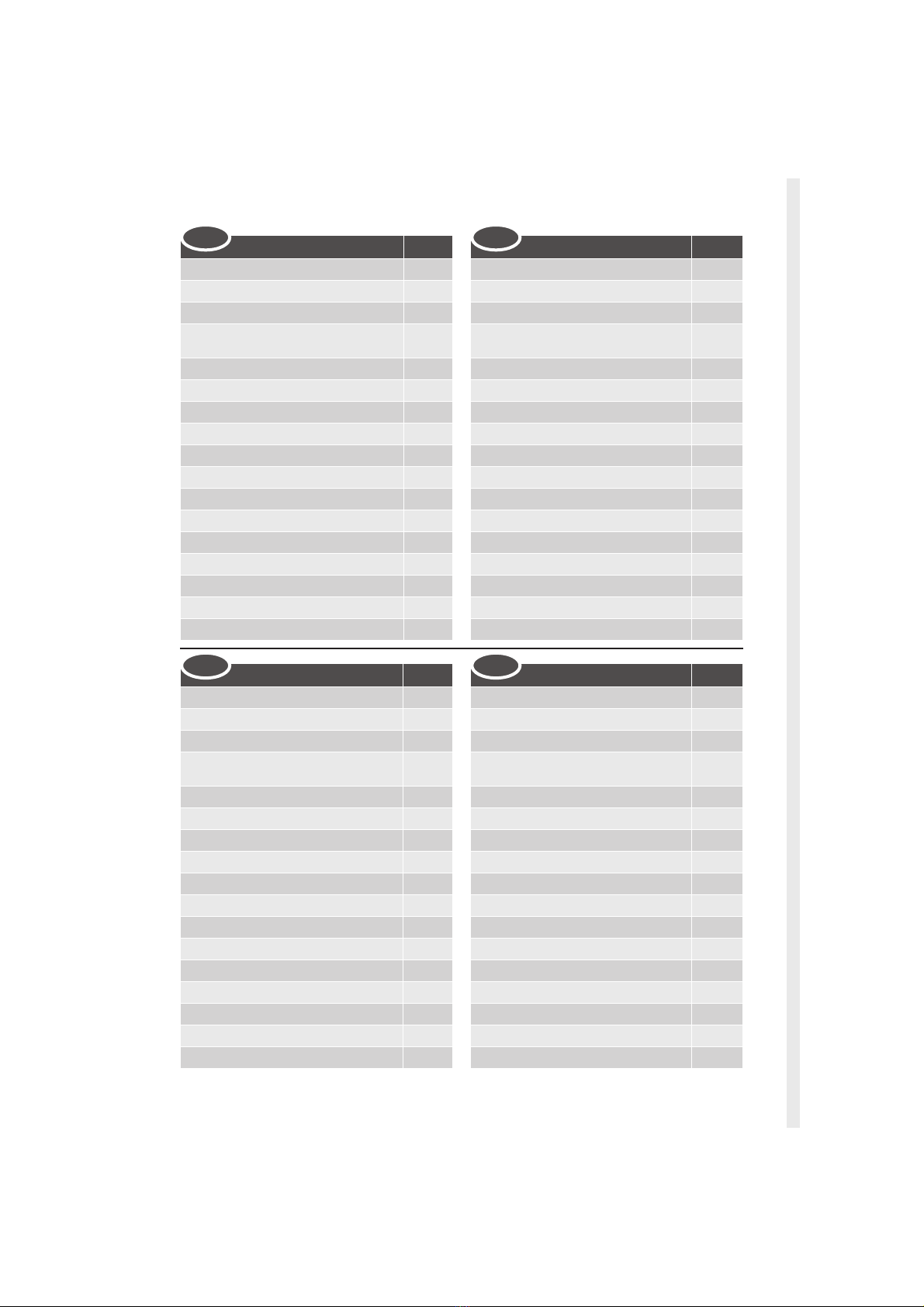

6

7

12

9

8

10

11

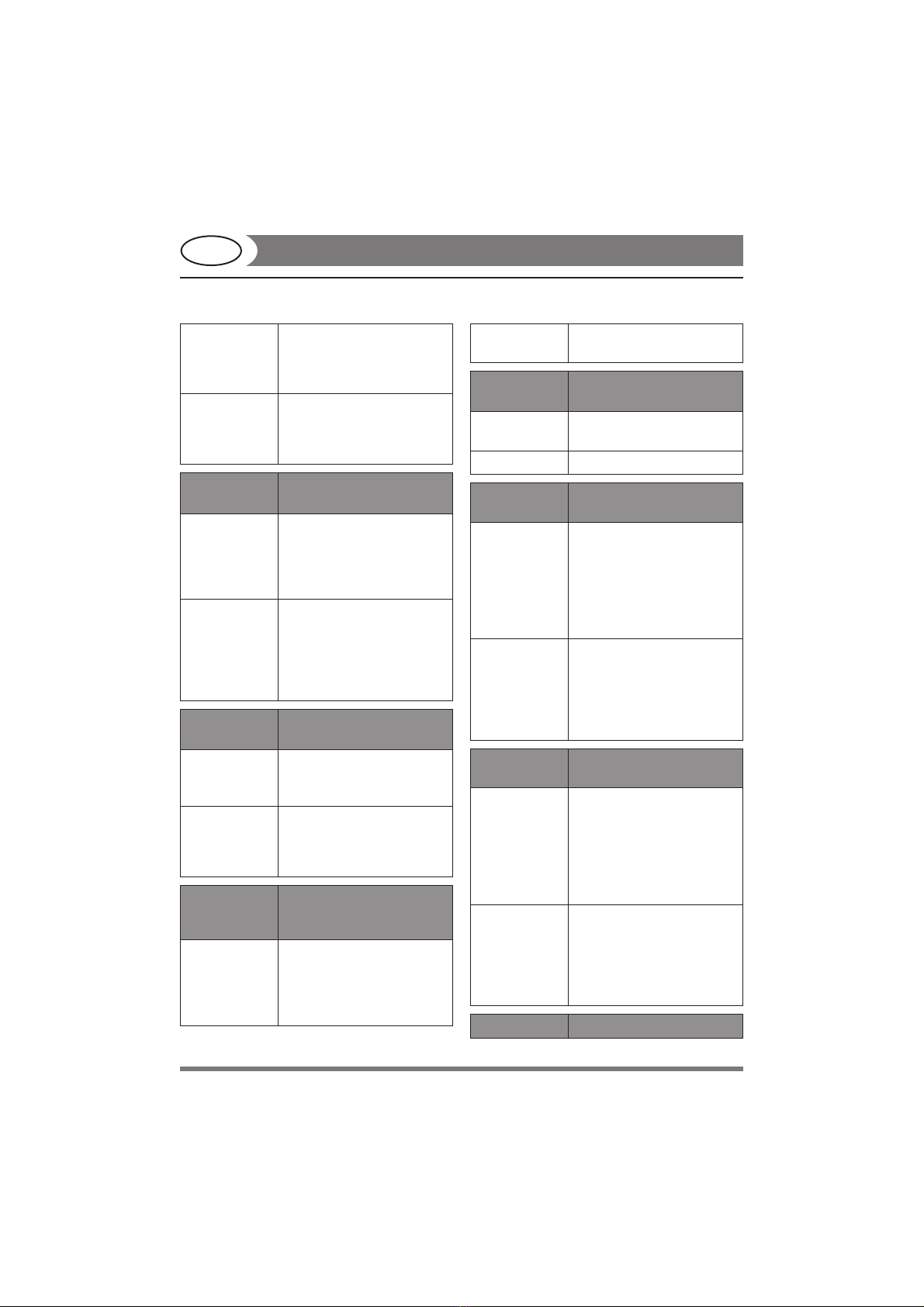

Fig. 1

> PRINCIPALI ORGANI DI COMANDOtMAIN CONTROLStPRINCIPAUX ORGANES

DE COMMANDEtHAUPTSCHALTERtPRINCIPALES ÓRGANOS DE CONTROLtHOOFDSCHAKELAARtΚΥΡΙΑ ΟΡΓΑΝΑ ΕΛΕΓΧΟΥtPRINCIPAIS ÓRGÃOS DE COMANDO

tPÄÄOHJAUSLAITTEET tОСНОВНЫЕ ОРГАНЫ УПРАВЛЕНИЯtGLAVNI KOMANDNI

DIJELOVI tGLAVNI DELI ZA UPRAVLJANJE

34

2

1

5

(IT)

1Interruttore elettropompa

2Interruttore bruciatore con regolatore

3Regolatore detergente

4Manometro

5Spie

6Uscita acqua alta pressione

7Entrata acqua + filtro

8Pistola

9Lancia

10 Tubo alta pressione

11 Raccordo portagomma

12 Ugello

(EN)

1Electropump switch

2Burner switch with regulator

3Detergent regulator

4Pressure gauge

5Pilot lights

6High pressure water outlet

7Water inlet + filter

8Gun

9Lance

10 High pressure hose

11 Rubber hose fitting

12 Nozzle

(FR)

1Interrupteur électropompe

2Interrupteur brûleur avec régulateur

3Régulateur détérgent

4Manomètre

5Voyants

6Sortie eau haute pression

7Entrée d’eau avec filtre

8Pistolet

9Lance

10 Flexible H.P.

11 Raccord porte-joint

12 Buse

(DE)

1Schalter Elektropumpe

2Schalter Brenner mit Einstellung

3Reinigungsmittel-Dosierknopf

4Manometer

5Kontrolllampen

6Wasseraustritt Hochdruck

7Einlauf + filter

8Pistole

9Lanze

10 Hochdruckschlauch

11 Anschluß Gummischlauch

12 Düse

(ES)

1Interruptor eléctrobomba

2Interruptor quemador con regulador

3Regulador detergente

4Manómetro

5Testigos

6Salida agua alta presión

7Entrada + filtro

8Pistola

9Lanza

10 Tubo alta presión

11 Racor del porta manguera

12 Boquilla

(NL)

1Schakelaar van de elektro pomp

2

Schakelaar van de verwarmer met regelaar

3Schoonmaakmiddelregelaar

4Manometer

5Controlelichtjes

6Hogedruk water uitlaat

7Wateringang met filter

8Pistool

9Lans

10 Hogedrukslang

11 Rubberslang verbindingsstuk

12 Spuitdop

(EL)

1∆ιακόπτης ηλεκτρικής αντλίας

2∆ιακόπτης καυστήρα με ρυθμιστή

3Ρυθμιστής απορρυπαντικού

4Μανόμετρο

5Προειδοποιητικές λυχνίες

6Έξοδος νερού υψηλής πίεσης

7Είσοδος νερού + φίλτρο

8Πιστόλι

9Σωλήνας εκτόξευσης

10 Σωλήνας υψηλής πίεσης

11 Συνδετικό εύκαμπτου σωλήνα

12 Ακροφύσιο

(PT)

1Interruptor bomba eléctrica

2

Interruptor do queimador com regulação

3Regulador detergente

4Manómetro

5Indicadores luminosos

6Saída água alta pressão

7Entrada água + filtro

8Pistola

9Lança

10 Tubo alta pressão

11 Junção porta borracha

12 Bico injector

(FI)

1Sähköpumpun katkaisin

2Polttimen katkaisin säätimellä

3Pesunesteen säädin

4Painemittari

5Merkkivalot

6Korkeapaineveden ulostulo

7Veden sisäänmeno + suodatin

8Pistooli

9Suihkuputki

10 Korkeapaineputki

11 Letkuliitos

12 Suutin

(RU)

1Выключатель электронасоса

2выключатель горелки с регулятором

3Регулятор моющего средства

4Манометр

5Индикаторы

6Выход воды под высоким давлением

7Вход воды + фильтр

8Пистолет

9Трубка опрыскивателя

10 Шланг высокого давления

11 Патрубок держателя шланга

12 Горелка

(HR)

1Prekidač električne pumpe

2Prekidač gorionika s regulatorom

3Regulator deterdženta

4Manometro

5Kontrolna svjetla

6Izlaz vode pod visokim pritiskom

7Ulaz za vodu + filtar

8Pištolj

9Usmjerivač

10 Cijev pod visokim pritiskom

11 Spojnica nosač gumice

12 Prskalica

(SL)

1Stikalo električne črpalke

2Stikalo gorilnika z regulatorjem

3Regulator čistila

4Manometer

5Signalne lučke

6Izstop vode z visokim tlakom

7Vstop vode + filter

8Brizgalka

9Brizgalna cev

10 Visokotlačna cev

11 Priključek gumijaste cevi

12 Šoba

INDICE pag.

Simboli - Installazione 5

Avviamento - Fuori servizio 6

Indicazioni generali - Avvertenze generali 7

Alimentazione idrica - Tubo ad alta pressio-

ne - Alimentazione elettrica 8-9

A.S.S. - Automatic Stop System 9

Uso previsto della macchina 9

Disimballo 10

Installazione ed avviamento 10

Aspirazione del detergente 10

Elementi di comando 11

Manutenzione 11

Inconvenienti e rimedi 12

Riparazioni - Ricambi 14

Pulizia caldaia 14

Condizioni di garanzia - Smaltimento 15

Caratteristiche tecniche 118-120

Certificato CE di Conformità 121

IT INDEX page

Symbols - Installation 5

Starting up - Switching off 6

General information - Safety precautions 16

Water supply - High pressure hose - Electric-

ity supply 17

A.S.S. - Automatic Stop System 18

Suitable use of the machine 18

Unpacking 18

Installation and start-up 18

Detergent suction 19

Control components 19

Maintenance 20

Troubleshooting 20

Repairs - Spare parts 23

Boiler cleaning 23

Warranty conditions - Disposal 24

Technical data 118-120

CE Certificate of Conformity 121

EN

SOMMAIRE page

Symboles - Mise en place 5

Demarrage - Extinction de l’appareil 6

Indications générales - Avertissements 25

Alimentation en eau - Tuyau haute pression

- Alimentation électrique 26-27

A.S.S. - Automatic Stop System 27

Utilisation prevue de la machine 27

Deballage 27

Installation et mise en marche 28

Aspiration du detergent 28

Éléments de commande 29

Entretien 29

Inconvenients et remèdies 30

Reparations - Pièces de rechange 32

Nettoyage chaudière 32

Conditions de garantie - Èlimination 33

Caracteristiques tecniques 118-120

Certificat CE de Conformité 121

FR INHALTSVERZEICHNIS Seite

Symbole - Installation 5

Inbetriebnahme - Betrieb beenden 6

Allgemeine Hinweise - Warnhinweise 34

Wasserversorgung - Hochdruckschlauch -

Stromversorgung 35

A.S.S. - Automatic Stop System 36

Einsatzbereiche der Maschine 36

Auspacken der MAschine 36

Installation und Anlassen 36

Ansaugen des Reinigungsmittels 37

Betätigungselemente 37

Wartung 38

Störungen und Abhilfen 39

Reparaturen - Ersatzeile 41

Kesselreinigung 41

Garantiebedingungen - Entsorgung 42

Tecnische Angaben 118-120

CE-Konformitätsbescheinigung 121

DE

SISÄLTÖ sivu

Symbolit - Asennus 5

Käyttöönotto - Käytön lopetus 6

Yleiset ohjeet - Varoitusohjeet 80

Vedensyöttö - Korkeapaineletku - Sähkön-

syöttö 81-82

A.S.S. - Automatic Stop System 82

Koneen käyttötarkoitus 82

Pakkauksesta purkaminen 82

Asennus ja käyttöönotto 83

Pesuaineen imu 83

Ohjauslaitteet 84

Huolto 84

Viat ja niiden korjaus 85

Korjaukset - Varaosat 87

Kuumavesisäiliön puhdistaminen 87

Takuuehdot - Romutus 88

Tekniset tiedot 118-120

EU-Vaatimustenmukaisuusvakuutus 122

FI ОГЛАВЛЕНИЕ стр.

Символы - Монтаж 5

Пуск - Хранение 6

Общие Указания - Общие Предупреждения 89

Подача воды - Шланг высокого давления

- Система Электропитания 90-91

A.S.S. - Система автоматического останова 91

Предусмотренное пользование машиной 91

Распаковка 92

Установка и запуск 92

Всасывание моющего средства 92

Элементы управления 93

Техобслуживание 94

Неисправности и способы их устранения 94

Ремонт - Запасные части 96

Чистка котла 96

Условия гарантии - Утилизация 96-97

Технические характеристики 118-120

Сертификат Соответствия ЕС 122

RU

SADRŽAJ str.

imboli - Instalacija 5

Pokretanje – Van uporabe 6

Opće indikacije – Opća upozorenja 100

Napajanje vodom – Cijev pod visokim

pritiskom -Električno napajanje 101-102

A.S.S. - Automatic Stop System 102

Predviđena uporaba stroje 102

Uklanjanje ambalaže 103

Instalacija i pokretanje 103

Usisavanje deterdženta 103

Elementi komande 104

Održavanje 104

Problemi i rješenja 105

Popravljanje – Rezervni dijelovi 107

Čišćenje grijalice(kotla) 107

Garantni uvjeti - Odbacivanje 108

Tehničke karakteristike 118-120

Izjava CE o Prikladnosti 123

HR KAZALO str.

Simboli - montaža 5

Zagon – mirovanje 6

Splošna navodila – splošna opozorila 109

Dovod vode – visokotlačna cev -električno

napajanje 110-111

A.S.S. - Automatic Stop System 111

Predvidena uporaba stroja 111

Odpakiranje 112

Namestitev in zagon 112

Sesanje čistila 112

Elementi za upravljanje 113

Vzdrževanje 113

Težave in rešitve 114

Popravila - nadomestni deli 116

Čiščenje kotla 116

Garancijski pogoji - odstranjevanje 117

Tehnične lastnosti 118-120

CE izjava o ustreznosti 80

SL

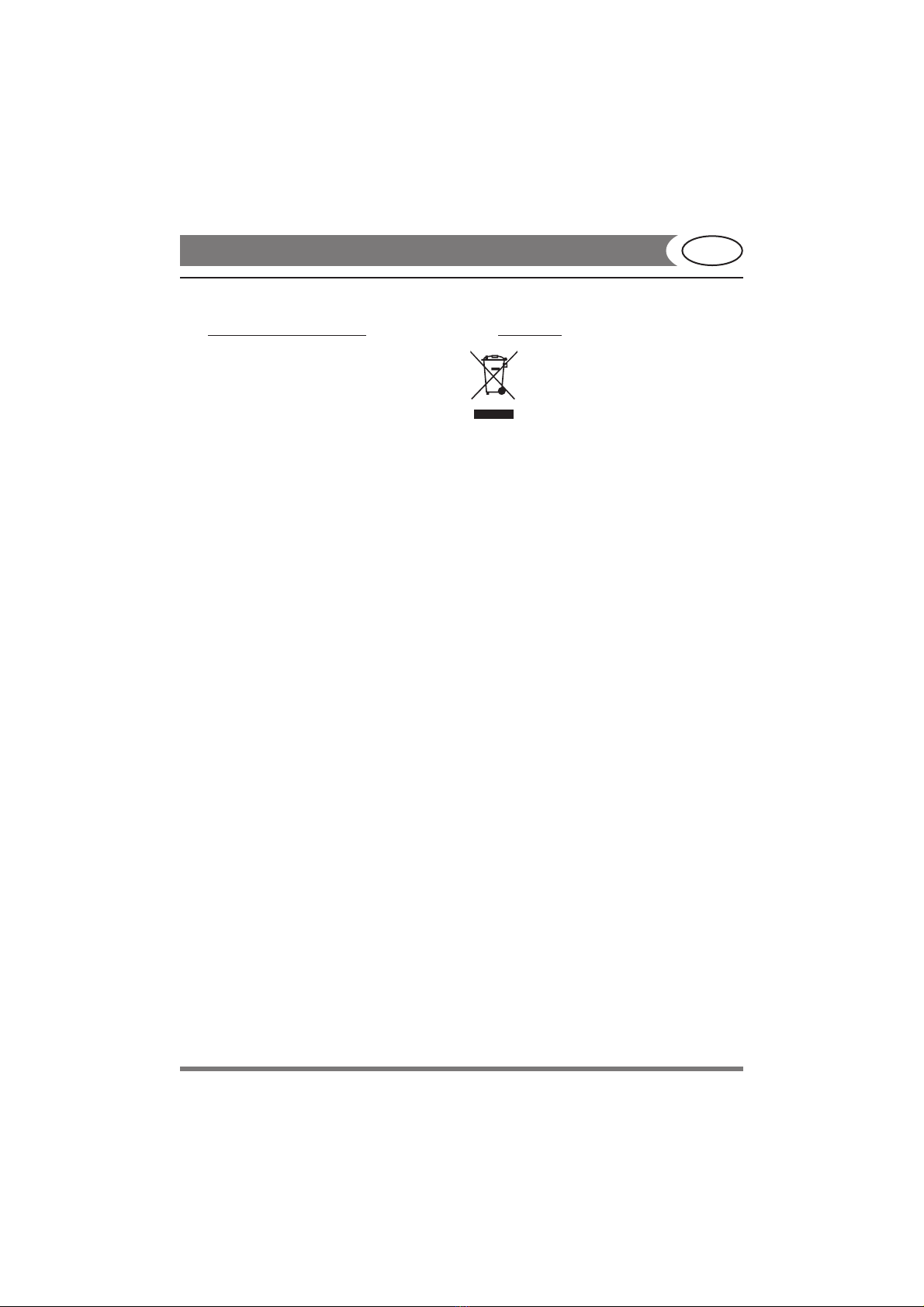

5

OFF

optional

1. 2. 3. 4.

JODItNN

5. 5B. 6. 7.

CLICK!

5÷40°C

NJOMNJOtNBY.1B

NJO

8. 9.

ATTENZIONE! Prestare attenzione per motivi di sicurezza.

CAUTION! It is important to be careful on safety grounds.

ATTENTION! Redoublez d’attention pour des motifs de sécurité.

ACHTUNG! Wichtiger Hinweis, der aus Sicherheitsgründen zu beachten ist.

¡ATENCIÓN! Prestar atención por motivos de seguridad.

ATTENTIE! Uit veiligheidsoverwegingen goed opletten.

ΠΡΟΣΟΧΗ! Σημαντική υπόδειξη που πρέπει να τηρηθεί για λόγους ασφαλείας.

ATENÇÃO! Informação importante a ser tida em consideração por motivos de segurança.

HUOMIO! Tärkeä ohje joka on turvallisuussyistä otettava huomioon.

ВНИМАНИЕ! Для обеспечения безопасности будьте внимательны.

UPOZORENJE! Pripazite iz sigurnosnih motiva.

POZOR! Bodite pozorni iz varnostnih razlogov

*.1035"/5&t*.1035"/5t*.1035"/5t8*$)5*(t*.1035"/5&t#&-"/(3*+,tƨƝƢƗƣƩƟƠƥt*.1035"/5&t53,&tǭǟǯǞDZǧDZǤВНИМАНИЕ t7"Ç/0t10.&.#/0> SIMBOLItSYMBOLStSYMBOLEStSYMBOLEtSÍMBOLOStSYMBOLENtΣΥΜΒΟΛΑtEXPLICAÇÃO DOS SÍMBOLOS tSYMBOLITtСИМВОЛЫtSIMBOLI tSIMBOLI

> INSTALLAZIONEtINSTALLATIONtMISE EN PLACEtINSTALLATIONtINSTALACIÓNtINSTALATIEtΕΓΚΑΤΑΣΤΑΣΗtINSTALAÇÃO tASENNUS tМОНТАЖ tINSTALACIJA t.0/5"Ç"

OK

6

OFF

1. 2. 3. 4.

5. 6. 7.

0°C

> AVVIAMENTOtSTARTING UPtDEMARRAGEtINBETRIEBNAHMEtPUESTA EN MARCHA

tINGEBRUIKNAMEtΘΕΣΗ ΣΕ ΛΕΙΤΟΥΡΓΙΑtCOLOCAÇÃO EM FUNCIONAMENTO tKÄYTTÖÖNOTTO tПУСК tPOKRETANJE tZAGON

> FUORI SERVIZIOt48*5$)*/(0''tEXTINCTION DE L’APPAREILtBETRIEB BEENDEN

tPARA DEL APARATOtAPPARAAT UITSCHAKELENtΤΕΡΜΑΤΙΣΜΟΣ ΛΕΙΤΟΥΡΓΙΑΣ tTERMINAR A OPERAÇÃO tKÄYTÖN LOPETUS tХРАНЕНИЕ tVAN UPORABE tMIROVANJE

EN

16

> GENERAL INFORMATION

t5IJTBQQMJBODFTQFSGPSNBODFBOEVTFSG-

riendliness make it suitable for PROFES-

SIONAL use.

t5IFBQQMJBODFDBOCFVTFEGPSXBTIJOHsurfaces outdoors, whenever pressurised

water is required to remove dirt.

t8JUITQFDJBMPQUJPOBMBDDFTTPSJFTJUDBObe used for foaming and sandingblasting,

and for washing with a rotary brush for ap-

plication to the gun.

> SAFETY PRECAUTIONS

E$"65*0/*UJTJNQPSUBOUUPCFDBSFGVMPOTBGFUZHSPVOETE8"3/*/(This appliance is for outdoor

use only.

E8"3/*/(Always disconnect the elec-

tricity and water supplies on completion

of every job.

E8"3/*/(Never use the appliance if the

electrical cable or important parts of the

appliance are damaged, e.g. safety devic-

es, high pressure hose, gun, etc.

E8"3/*/(This appliance has been de-

signed for use with the detergent provided

or the detergent specified by the manu-

facturer, such as a neutral shampoo based

on biodegradable anionic surface active

detergents. The use of other detergents or

chemicals may put the appliance’s safety

at risk.

E8"3/*/(Never use the appliance with

people in the vicinity, unless they are

wearing protective clothing.

E8"3/*/(Do not direct the nozzle to-

ward mechanical parts containing lubri-

cant grease, as the grease will dissolve and

spread over the surrounding ground. Vehi-

cle tyres/tyre valves may only be cleaned

from a minimum distance of 30 cm, oth-

erwise the vehicle tyre/tyre valve could

be damaged by the high-pressure jet. The

first indication of this is a discoloration

of the tyre. Damaged vehicle tyres/tyre

valves can be deadly dangerous.

E8"3/*/(High pressure jets may be dan-

gerous if improperly used. Jets must never

be pointed at people, animals, life electri-

cal equipment or the appliance itself.

E8"3/*/(The hoses, accessories and

high pressure couplings are important for

the appliance’s safety. Use only hoses, ac-

cessories and couplings recommended by

the manufacturer (it is extremely impor-

tant to protect these components against

damage by avoiding their improper use

and protecting them against bending,

knocks and scratches).

E8"3/*/(the gun is fitted with a safety

catch. Whenever use of the machine is

interrupted it is important to operate the

safety catch to prevent accidental activa-

tion of the jet.

- Never point the jet at yourself or others to

clean clothing or footwear.

- Never allow children or untrained people

to use the appliance.

- Safety features: gun equipped with safety

locking device, appliance equipped with

(Class I) overload cutout, pump equipped

with by-pass valve or shutdown device.

- The safety button on the gun is not there

to lock the lever during operation, but to

prevent its accidental operation.

E8"3/*/(Appliances not equipped with

A.S.S. – Automatic Stop System: must not

be left in operation for more than 2 min-

utes with the gun released. The recycled

water heats up considerably, seriously

damaging the pump.

E8"3/*/(Appliances equipped with

A.S.S – Automatic Stop System: these ap-

pliances should not be left in standby for

more than 5 minutes.

E8"3/*/(Switch the appliance off com-

pletely (master switch on OFF) whenever it

is left unattended.

E8"3/*/(Every machine is tested in its

operating conditions, so it is normal for a

few drops of water to be left inside it.

E8"3/*/(Take care not damage the elec-

17

EN

tric cable. Have a damaged power cord

replaced immediately by an authorized

service point or an electrical specialist.

E8"3/*/(Appliance with fluid under

pressure. Keep a firm hold on the gun and

be prepared to take the kickback pressure.

Only use the high pressure nozzle provid-

ed with the appliance.

E8"3/*/(The high pressure hose is de-

signed and produced to withstand high

pressures. To avoid damage, it must be

handled with special care. Misuse may

lead to premature breakages or damage

and cause the loss of warranty cover.

E8"3/*/(The appliance is not to be used

by children or persons with reduced physi-

cal, sensory or mental capabilities, or lack

of experience and knowledge, unless they

have been given supervision or instruc-

tion.

E8"3/*/(Children being supervised not

to play with the appliance.

E8"3/*/(Never start the high-pressure

cleaner without first completely unwind-

ing the high-pressure hose.

E8"3/*/(When winding and unwinding

the pipe take care not to cause the high-

pressure cleaner to overturn.

E8"3/*/(Before unwinding or wind-

ing the hose, switch the machine off and

release the pressure in the hose itself

(switching off).

> 8"5&34611-:8BUFSTVQQMZDPOOFDUJPO$BVUJPO%BOHFSOnly clean or filtered water should be used

for intake. The delivery of the water intake tap

should be equal to the double of the maximum

pump range.

Minimum delivery rate: 30 l/ min.-

Maximum intake water temperature: 40°C-

Max inlet water pressure: 1Mpa-

Place the cleaner as close to the water supply

system as possible.

Water supply from the water main

t$POOFDUBTVQQMZIPTFOPUJODMVEFEUPthe water inlet of the unit (ref. 6, pos. 1)

and to the water supply (max. pressure 10

bar).

tConnect high pressure hose to the ma-

chine connection (ref. 6, pos. 2) and turn

on the water tap.

The cleaner can be connected directly to the

mains drinking water supply hose is fitted with

a backflow preventer valve as per current regu-

lations in force.

Make sure that the hose is at least Ø 13 mm and

that it is reinforced.

Failure to comply with the above conditions

causes serious mechanical damage to the

pump and the loss of warranty cover.

> HIGH PRESSURE HOSE

E8"3/*/(The high pressure hose is de-

signed and produced to withstand high

pressures. To avoid damage, it must be

handled with special care.

Misuse may lead to premature breakages or

damage and cause the loss of warranty cover.

(See illustrations).

> ELECTRICITY SUPPLY

- The appliance’s electrical connection must

comply with the IEC 364 standard.

Before connecting the appliance, make

sure that the nameplate data are the same

as those of the electrical mains and that

the socket is protected by a differential

security breaker with tripping sensitivity

below 0.03 A - 30 ms.

- If the appliance’s plug is not compatible

with the socket, have the socket replaced

with another of suitable type by profes-

sionally qualified staff.

- Never use the appliance in ambient tem-

peratures below 0° C if it is equipped with

a PVC (H VV-F) cable.

E8"3/*/(Inadequate extension cords

can be dangerous.

EN

18

- If an extension lead is used, the plug and

socket must be watertight and the cable

must have the dimensions shown in the

table below. JGmUUFE

PLEASE NOTE: This water cleaner is equipped

with the A.S.S. (Automatic Stop System), which

stops the machine during the bypass phase. To

start the water cleaner, it is therefore necessary

to set the switch on position “ON”; after that

press the pistol trigger: the Automatic Stop

System will start the machine and will stop it

automatically when the trigger is released. It is

advisable to put on the safety of the pistol trig-

ger whenever the machine is stopped, in order

to avoid unintentional starting.

t"OZBVUPNBUJDTUBSUPGUIFNBDIJOFXJUI-

PVUQSFTTJOHUIFHVOUSJHHFSJTBUUSJCVUBCMFUPBJSCVCCMFTJOUIFXBUFSPSPUIFSTJNJMBSQIFOPNFOBXIJDIEPOPUJNQMZUIFFYJTU-

FODFPGBOZEFGFDUTJOUIFNBDIJOFt%POPUMFBWFUIFBQQMJBODFVOBUUFOEFEEVSJOHUIFTUBOECZGPSNPSFUIBONJOVUFT$POUSBSJMZGPSUIFTBGFUZPGUIFBQQMJBODFJUJTOFDFTTBSZUPSFUVSOUIFTXJUDIJOUPUIFOFF position.

t1MFBTFDIFDLUIBUUIFDPVQMJOHPGUIFIJHIQSFTTVSFIPTFXJUIUIFBQQMJBODFBOEUIFHVOTVQQMJFEBTTUBOEBSEFRVJQNFOUTNBEFDPS-

SFDUMZUIBUJTUPTBZXJUIPVUBOZXBUFSMFBL*GUIFBQQMJBODFJTFRVJQQFEXJUIBQSFTTVSFSFHVMBUPStXIFOUIFQSFTTVSFJTTFUUPNJOJNVNUIF"44NBZOPUUSJHHFS5IFSFGPSFEPOPUBM-

MPXUIFBQQMJBODFUPGVODUJPOJOCZQBTTGPSNPSFUIBONJOVUFtEPOPUBDUPOUIFHVOMFWFSUPPGSFRVFOUMZUIJTNBZDBVTFBNBMGVODUJPO> SUITABLE USE OF THE MACHINE

The performances of the machine are suitable

for a professional use. Structural technologies

have been studied to assure high reliability and

safety levels, and long life. It is absolutely for-

bidden to use the machine in potentially explo-

sive environments or areas.

The working temperature must range between

+ 5° and + 50°C. It is forbidden to carry out any

modification to the structure and to any ele-

ments of the machine.

CORRECT USE OF THE MACHINE

t5IFDMFBOFSNVTUCFQMBDFEPOBmSNTUBCMFsurface and must be horizontal.

t*ODBTFPGPQFSBUJPOJOEPPSTBEFRVBUFWFOUJ-

lation and gas venting must be assured.

t8IFOFWFSVTJOHUIFIJHIQSFTTVSFDMFBOFSusers are urged to hold the gun in the correct

position, with one hand on the grip and the

other on the spray rod.

t5IFXBUFSKFUNVTUOFWFSCFQPJOUFEBUUIFelectrical cables or at the machine.

> UNPACKING

Take out the upper and the lower hooks, which

fix the cardboard box to the pallet, take the card-

board box off, put two wheels of the machine

on ground and take the pallet off (see ref. 2).

> INSTALLATION AND START-UP

1ST START-UP

When starting up for the first time or after a

long period out of use, connect the intake line

only for a few minutes so that any dirt is vented

from the delivery outlet.

ELECTRICAL CONNECTION (Ref. 3)

Check that the mains voltage is the same as

that of your machine, indicated on the techni-

cal data plate. Your electrical system must be

constructed by qualified technicians capable of

working in accordance with the requirements

of the regulations in force (earth connection,

230-240V 400-415V

3G 2,5 mm24G 2,5 mm2

max 20 m max 30 m

19

EN

fuses, differential security breaker, etc).

*ODBTFPGGBJMVSFUPDPNQMZXJUIPOFPGUIFSFHVMBUJPOTTUBUFEBCPWFUIFNBOVGBDUVSFSEFDMJOFTBMMSFTQPOTJCJMJUZGPSUIFTUBõBOEQSPWJEFTOPXBSSBOUZ'*--*/(618*5)'6&-Fill the tank with the fuel indicated on the tech-

nical data plate (Diesel, ref. 4).

Avoid that thetankisemptywhen themachine is

running in order not to damage the fuel pump.

E*ODPSSFDUGVFMTIBMMOPUVTFEBTUIFZBTQSPWJEFIB[BSEFill up the detergent tank with the suggested

products, suitable for the kind of washing to be

carried out (ref. 4).

ECAUTION:.BLFVTFPOMZPGMJRVJEEFUFS-

HFOUEPOPUBCTPMVUFMZVTFBDJEPSUPPNVDIBMLBMJOFQSPEVDUTWesuggest you to

make use of our products, which have been

studied for the use with washer machines.

START-UP

Switch on the machine by pressing the switch

(ref. 1, pos.1) and leave it to run for a few min-

utes to eliminate any dirt and air bubbles from

the water circuit, then switch it off, connect the

high pressure line to the spray gun (ref. 7) and

fit the spray rod (ref. 8). Make sure that the de-

tergent regulator is in the closed position.

When the machine is running again, check that

the jet is even; otherwise, clean the nozzle to

remove any dirt. Wait a few seconds for the op-

erating pressure to be reached, then operate

the gun for two or three short bursts.

To wash with hot water, turn the burner switch

and select the desired temperature setting (ref.

1, pos. 2). To add detergent or disinfectant to

the water jet, open the regulator (ref. 1, pos. 3)

to the setting for the quantity required as de-

scribed in the “DETERGENT SUCTION” section.

> LANCE ASSEMBLY

To fit the lance to the gun, it is sufficient to in-

sert the threaded end of the lance (ref. 8, pos.

1) into the hole on the gun (ref. 8, pos. 2); then

screw the lance as shown by the arrow (A) until

the connection is tight.

> DETERGENT SUCTION

Automatic Detergent suction at tap opening

(ref. 9, pos. 1).

When you start the machine, the mixing of the

detergent with the water is automatic at the

water passage. The quantity of sucked deter-

gent depends on the quantity set with the de-

tergent adjusting knob (ref. 9, pos. 1).

ECAUTION:.BLFVTFPOMZPGMJRVJEEFUFS-

HFOUEPOPUBCTPMVUFMZVTFBDJEPSUPPNVDIBMLBMJOFQSPEVDUTWe suggest you to

make use of our products, which have been

studied for the use with washer machines.

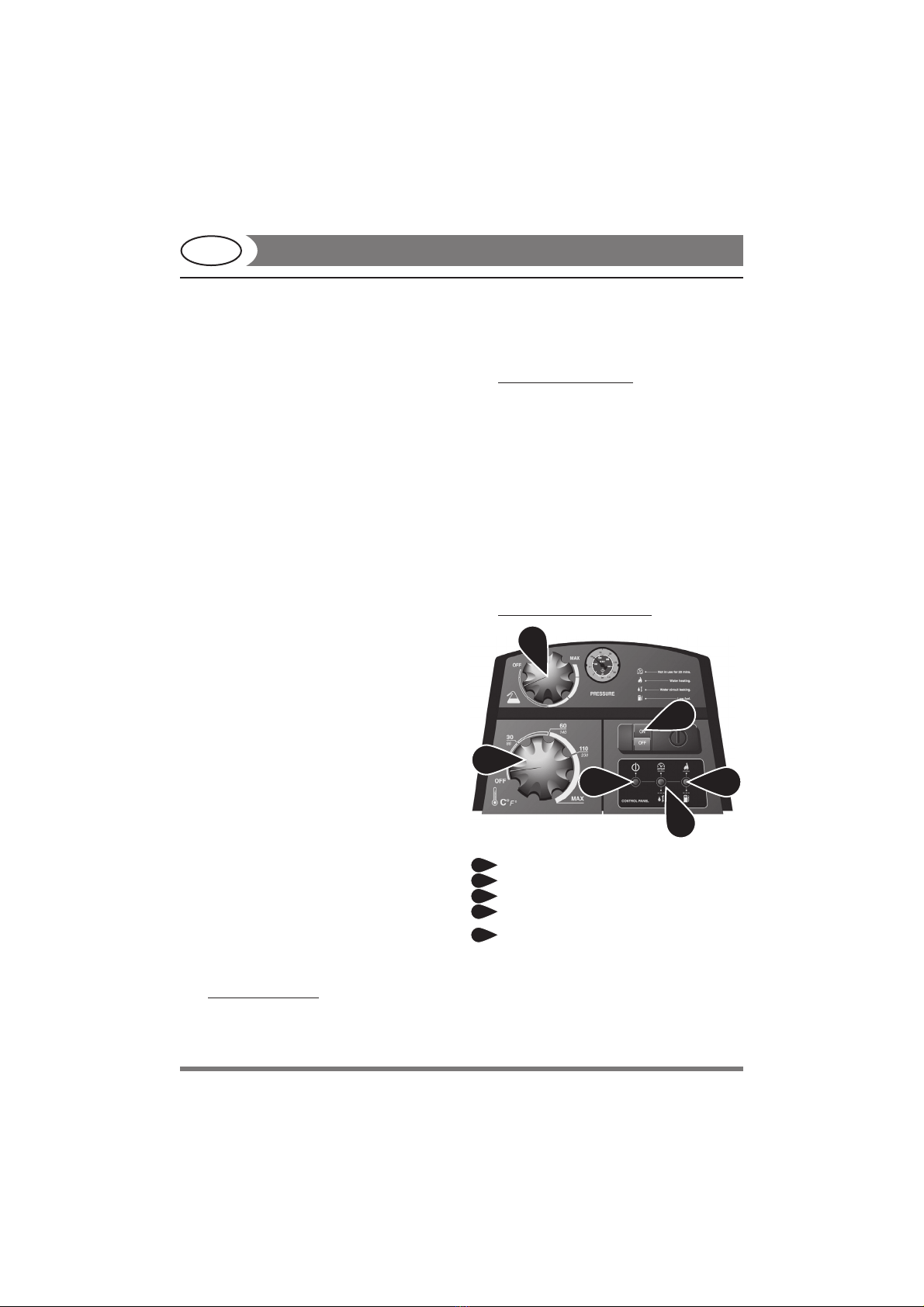

> CONTROL COMPONENTS

$0/530-48*5$)&41Motor pump switch

2Burner switch with regulator

3Detergent regulator

4Pilot lights

4A:Motor pump ON green pilot light

B: Leak pilot light

- flashes when the pistol lever is repeat-

edly operated in a short time or when a

leak occurs in the high pressure circuit.

Remove the leak, referring to an au-

thorized service centre.

- remains ON when the machine is left

1

2

3

4B

4A 4C

EN

20

in stand-by for over 20 minutes.

Switch on and off the motor pump

switch.

C: Burner switch

- flashes when the gasoil tank is emp-

ty; the burner is stopped.

Refuel.

- remains ON when the burner switch-

es on.

> GUN SAFETY DEVICE

Whenever the machine has to be stopped, it is

important to engage the safety catch (S, ref. 10)

on the gun so that it cannot be operated acci-

dentally.

> DESCALING (REF. 5)

The descaling procedure must be carried out pe-

riodically with specific products. The interval de-

pends on the hardness of the water. This opera-

tion should be carried out by our after-sales serv-

ice, since the descaling product may cause wear

of components. Comply with the regulations in

force when disposing of the descaling agent.

tLiquid softener tank (ref. 5, pos. 1)

Fill the softener tank with our products (in all

cases, with non corrosive products). The dis-

pensing rate is set at a medium value; the After

Sales Services will be able to adapt the setting

to local conditions.

> MAINTENANCE

IMPORTANT: #FGPSFEPJOHBOZXPSLPOUIFDMFBOFSEJTDIBSHFUIFQSFTTVSFBOEEJTDPOOFDUUIFFMFDUSJDJUZBOEXBUFSTVQQMJFT.

CHECKING THE PUMP OIL LEVEL

Check the oil level periodically. The oil must

be changed for the first time after 50 working

hours, with subsequent changes every 500

hours. SAE 20/30 oil is recommended - Oil ca-

pacity 0,7 Kg

$)&$,*/(5)&8"5&3*/5",&'*-5&3Inspect and clean the water intake filter (ref. 11)

on the intake union periodically. This is impor-

tant to prevent fouling which may impair op-

eration of the pump.

REPLACING THE SPRAY ROD NOZZLE

Replace the nozzle when the pressure drops

below the normal values.

ELECTRIC MOTOR

If the motor malfunctions, it cuts out. Wait 5-10

minutes before restarting. If the problem per-

sists, refer to the“TROUBLESHOOTING” section.

If you are still unable to eliminate the problem,

stop using the machine and contact an Author-

ized Service Centre.

ELECTRICAL CORD

E8"3/*/(Take care not damage the elec-

tric cable. Have a damaged power cord re-

placed immediately by an authorized serv-

ice point or an electrical specialist.

CLEANING THE FUEL FILTER

Check the fuel filter (ref. 12) periodically and

replace if it has deteriorated or is excessively

dirty.

> ELECTRIC DIAGRAM

See illustrations, page 82.

> 8"5&3%*"(3".See illustrations, page 82.

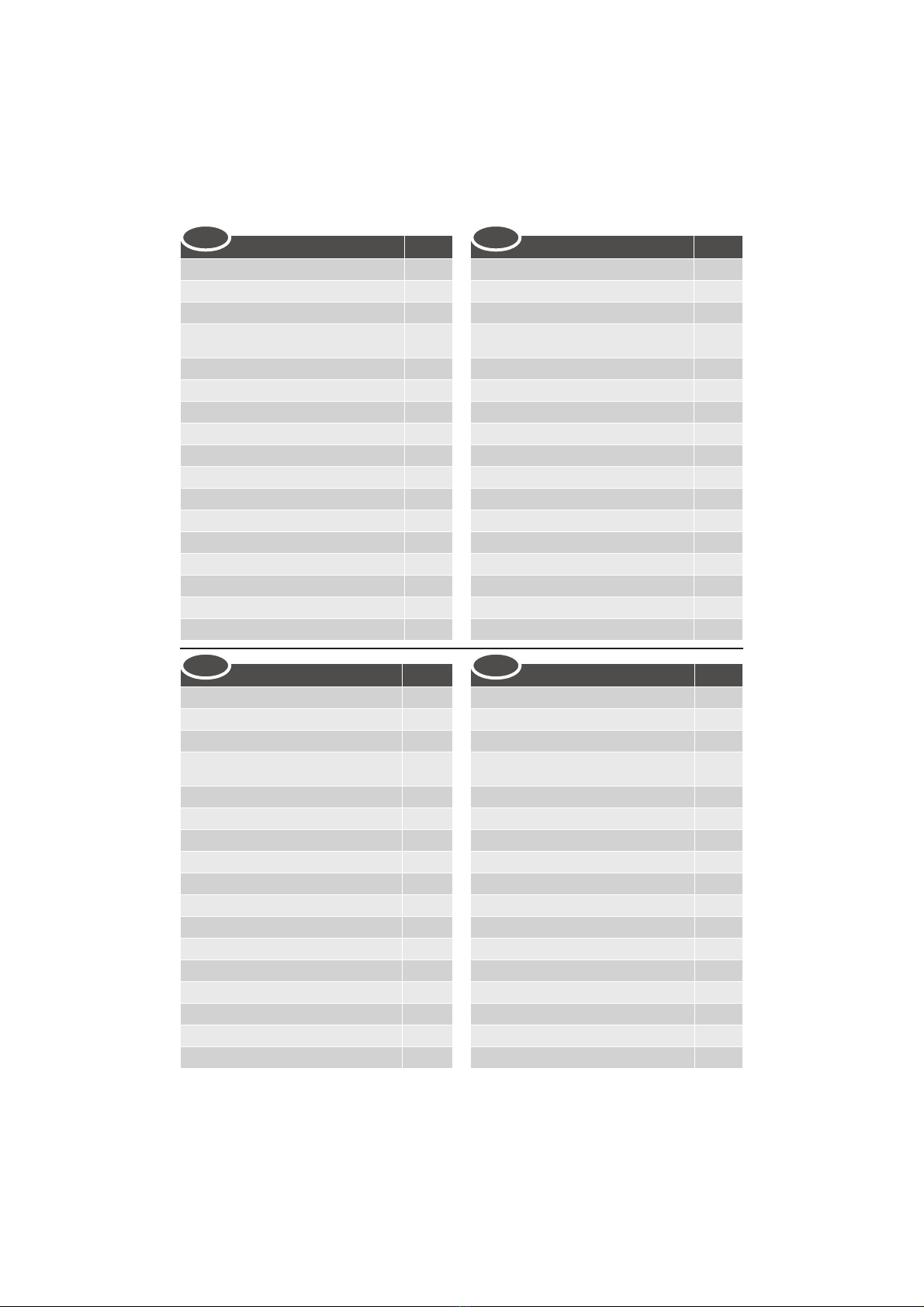

> TROUBLESHOOTING

Before doing any work on the machine, discon-

nect the electricity and water supplies and dis-

charge the pressure. Proceed systematically to

identify faults following the chart below; if you

are still unable to eliminate the problem, call in

the "VUIPSJ[FE"GUFS4BMFT4FSWJDF.

'BVMU

8IFOUIFNBJOTXJUDIJTUVSOFEPOUIFNBDIJOFEPFTOPUTUBSU

21

EN

$BVTF

tPlug not properly connect-

ed.

tConnection panel fuses

are burnt out.

Repair tCarefully check the plug

and the electric cable.

tCheck them and replace

them.

'BVMU

5IFNPUPSIVNTCVUEPFTnot start

$BVTF

tA phase is missing (in

three phase models).

tLows voltage.

tHigh pressure pump is

blocked.

Repair tContact an authorised

service centre.

tContact an authorised

service centre.

tContact an authorised

service centre.

'BVMU

5IFNPUPSTUPQTTVEEFOMZPSBGUFSBXIJMF

$BVTF

tThe motor-protecting

switch is on because of in-

sufficient mains voltage.

Repair tCheck the value of the

mains voltage.

tContact an authorised

service centre.

'BVMU

8IFOUIFMBODFJTUVSOFEPOQSFTTVSFWBMVFTEF-

DSFBTFBOEJODSFBTF

$BVTF

tThe nozzle is either

clogged or deformed.

tEither boiler coil or lance

are clogged with lime-

stone.

Repair tEither clean it or replace it.

tDescaling.

'BVMU

5PNVDIWJCSBUJPOTBUUIFEFMJWFSZ

$BVTF

tThe valve are worn out or

dirty.

Repair tCheck and/or replace.

'BVMU

5IFQVNQEPFTOPUSFBDIUIFmYFEQSFTTVSFT

$BVTF

tThe pump sucks air.

tThe valves are worn out.

tThe setting valve area is

worn out.

tThe nozzle is unsuitable or

worn out.

tThe seals are worn out.

Repair tCheck the suction pipes.

tCheck and/or replace.

tContact an authorised

service centre.

tContact an authorised

service centre.

'BVMU

*SSFHVMBSQSFTTVSFnVDUVB-

tions

$BVTF

tThe suction and/or deliv-

ery valves are worn out.

tPresence of foreign mat-

ters in the valves, which

generate bad functioning.

tAir suction.

tThe seals are worn out.

Repair tCheck and/or replace.

tCheck and clean the re-

place.

tCheck the suction pipe.

tCheck and/or replace the

seals.

'BVMU

1SFTTVSFMFBLBHF

EN

22 $BVTF

tThe nozzle is worn out.

tThe suction and/or deliv-

ery valves are broken or

down.

tPresence of foreign mat-

ters in the valves, which

generate the valves bad

functioning.

tThe setting valve area is

worn out.

tThe seals are worn out.

Repair tReplace the nozzle.

tCheck and/or replace the

valves.

tCheck and clean the valves.

tCheck and/or replace the

setting valve area.

tReplace the seals.

'BVMU

Noisiness

$BVTF

tAir suction.

tThe suction and/or deliv-

ery valve springs are bro-

ken or down.

tForeign matters in the suc-

tion and delivery valves.

tThe bearings are worn out.

tExtreme liquid tempera-

ture.

Repair tCheck the suction pipes.

tReplace the valve springs.

tCheck and clean the suc-

tion and delivery valves.

tReplace the bearings.

tReduce the liquid temper-

ature.

'BVMU

8BUFSJTJOUIFPJM

$BVTF

tThe O-ring casing is worn

out.

tHigh moisture in the air.

tThe seals are completely

worn out.

Repair tCheck and/or replace the

O-ring.

tReplace the oil with dou-

ble frequency in respect

of the one suggested.

tReplace the seals.

'BVMU

'JMUSBUJPOTPGXBUFSGSPNUIFESBJOTCFUXFFODBTJOHBOEIFBE

$BVTF

tThe seals are worn out.

tThe piston is worn out.

tThe O-ring of the piston

cap is worn out.

Repair tReplace the seals.

tReplace the piston.

tReplace the seal.

'BVMU

'JMUSBUJPOTPGPJMGSPNUIFESBJOTCFUXFFOIFBEBOEcasing

$BVTF

tO-ring seals of casing are

worn out.

Repair tReplace the seals.

'BVMU

5VSOJOHPOUIFCVSOFSTXJUDIUIFCPJMFSEPFTOPUstart

$BVTF

tNo fuel.

tFuel filter is clogged.

tFuel pump is either

blocked or burnt out.

tDamaged thermostat.

tIgnition spark insufficient

or totally lacking.

tThe space among the

electrodes is not correct.

tBurn out fuse.

23

EN

Repair tCheck the level in the tank

and check whether the

rigid suction pipe is clean.

tReplace the line filter.

tReplace it.

tReplace it.

tContact an authorised

service centre.

tCheck the positioning.

tReplace it.

'BVMU

8BUFSJTOPUIPUFOPVHI

$BVTF

tPoor boiler performance.

tBoiler coil clogged with

limestone.

Repair tClean burner nozzle filter.

tClean fuel filter.

tCheck diesel pump pres-

sure.

tDescaling.

'BVMU

5PPNVDITNPLFGSPNUIFDIJNOFZ

$BVTF

tCombustion is not cor-

rect.

tImpurities or water in the

fuel.

Repair tClean fuel filter.

tClean the boiler.

tEmpty the tank and clean

it carefully.

tClean fuel filter as well.

'BVMU

*OTVöDJFOUEFUFSHFOUTVD-

tion

$BVTF

tNo detergent in the tank.

tIncrusted injector.

tEither coil or tube or lance

are clogged.

Repair tFill the detergent tank.

tClean it.

tEither cleaning or descal-

ing.

> REPAIRS - SPARE PARTS

For any problems not mentioned in this manu-

al, or if the machine breaks down, you are urged

to contact an "VUIPSJ[FE"GUFS4BMFT4FSWJDF

for the relative repair or for any replacement of

components with original spare parts. Use ex-

clusively original replacement parts.

> BOILER CLEANING

EATTENTION: 'PSBMMNBJOUFOBODFPGUIFCPJMFSPGUIFIJHIQSFTTVSFQVNQBOEPGUIFNBDIJOFJUJTOFDFTTBSZUPBEESFTTUPRVBMJmFEQFSTPOOFMPSUPBOBVUIPS-

J[FEBTTJTUBODFDFOUFS.

The boiler cleaning must be periodically ex-

ecuted every 180 ÷ 200 hours of working pro-

ceeding as follows:

Carefully remove the nozzle holder flange and

the electrodes holder (boiler head, ref. 13).

Clean with compressed air the nozzle filter and

check the electrodes position. (ref. 14).

Remove the boiler cap unscrewing the 3 nuts,

clean the deflector (ref. 15).

Manually take away the interior cap (ref. 16).

Unscrewing the locking nuts (ref. 17) and take

the boiler coil out.

Clean the coil by an iron brush (ref. 18).

Suck the residuums from the boiler (ref. 19).

Replace every parts doing the operations in the

inverse way.

1MFBTFOPUF5IFHFOFSBMDIFDLJOHBOEDPN-

CVTUJPOSFHVMBUJPONVTUCFQFSJPEJDBMMZFYFDVUFECZTQFDJBMJ[FEQFSTPOOFMBTQSF-

TDSJCFECZUIFMBX

EN

24

> 8"33"/5:$0/%*5*0/4All our machines are subjected to strict tests

and are covered against manufacturing de-

fects in accordance with applicable regulations

(minimum 12 months).The warranty is effective

from the date of purchase. If your high pressure

washer or accessories are handed in for repair, a

copy of the receipt must be enclosed.

(VBSBOUFFSFQBJSTBSFCFJOHNBEFPOUIFGPMMPXJOHDPOEJUJPOT- That defects are attrib-

utable to flaws or defects in materials or work-

manship. -That the directions of this instruction

manual have been thoroughly observed. - That

repair has not been carried out or attempted by

other than authorized service staff. - That only

original accessories have been applied. - That

the product has not been exposed to abuse

such as knocks, bumps or frost. - That only wa-

ter without any impurities has been used. -That

the high pressure washer has not been used for

rental nor used commercially in any other way.

5IFGPMMPXJOHBSFOPUJODMVEFEJOUIFXBS-

SBOUZ- Parts subject to normal wear. - The

high-pressure tube and optional accessories.

- Accidental damage, caused by transport, ne-

glect or inadequate treatment, incorrect or

improper use and installation failing to comply

with the indications in the instruction manual.

- The warranty shall not cover any cleaning op-

erations to which the operative components

may be subjected.

Repairs under this guarantee include replace-

ment of defective parts, exclusive of packing

and postage/carriage. The warranty shall not

cover replacement of the machine or extension

of the guarantee resulting from a breakdown.

The manufacturer declines all responsibility for

damage to persons or property caused by bad

installation or incorrect use of the machine.

8"3/*/(Failures, such as clogged nozzles,

valves and mechanism blocked due to lime-

stones, damaged pressure cleaner accessories

(like kinked high pressure hose) and/or appli-

ances normally working without any defects

ARE NOT COVERED BY THE WARRANTY.

> DISPOSAL

As the owner of electrical or electron-

ic equipment, the law (in accordance

with the EU Directive 2002/96/EC of

27 January 2003 on waste from elec-

trical and electronic equipment and

the national laws of the EU Member

States that have implemented this Directive)

prohibits you from disposing of this product or

its electrical / electronic accessories as munici-

pal solid waste and obliges you to make use of

the appropriate waste collection facilities.

The product can be disposed of by returning it

to the distributor when a new product is pur-

chased. The new product must be equivalent to

that being disposed of.

Disposing of the product in the environment

can cause great harm to the environment itself

and human health.

The symbol in the figure indicates the urban

waste containers and it is strictly prohibited to

dispose of the equipment in these containers.

Non-compliance with the regulations stipulat-

ed in the Directive 2002/96/EC and the decrees

implemented in the various EU Member States

is administratively punishable.

80

FI

> YLEISET OHJEET

t-BJUUFFOPNJOBJTVVEFUKBTFOIFMQQPLÊZU-

tö tekevät sen sopivaksi EI-AMMATTIMAI-

SEEN KÄYTTÖÖN.

t-BJUFUUBWPJEBBOLÊZUUÊÊVMLPUJMPKFOQJOUP-

jen pesemiseen, kun paineen alaista vettä

tarvitaan lian poistoon.

t-BJUUFFTFFOPOTBBUBWJTTBMJTÊWBSVTUFJUBvaahdon levitykseen, hiekkapuhalluksen

tai pesu voidaan suorittaa pesukahvavar-

ren päähän kiinnitettävällä pyörivällä har-

jalla.

> VAROITUSOHJEET

E)60.*05ÊSLFÊPIKFKPLBPOUVSWBMMJ-

TVVTTZJTUÊPUFUUBWBIVPNJPPOEHUOMIO: Laitetta saadaan käyttää aino-

astaan ulkona.

EHUOMIO: Jokaisen käytön jälkeen on säh-

kön- ja vedensyöttö kytkettävä aina pois

päältä.

EHUOMIO: Älä käytä laitetta, jos virtajohto

tai laitteen tärkeät osat ovat vaurioituneet,

esim. turvalaitteet, pesukahvan korkeapai-

neletku jne.

EHUOMIO: Tämä laite on kehitetty valmis-

tajan toimittamien ja määräämien puhdis-

tusaineiden (tyyppi: neutraali biologisesti

hajoaviin anionisiin tensiideihin pohjau-

tuva puhdistusshampoo) käyttöä varten.

Muiden puhdistusaineiden tai kemiallis-

ten aineiden käyttö voi vaikuttaa laitteen

turvallisuuteen.

EHUOMIO: Laitetta ei saa käyttää henkilöi-

den läheisyydessä, jos heillä ei ole suoja-

vaatetusta.

EHUOMIO: Ruiskuputken suihkua ei saa

suunnata voitelurasvaa sisältäviin mekaa-

nisiin osiin: päinvastaisessa tapauksessa

rasva liukenee ja hajoaa maaperään. Au-

ton renkaita/venttiileitä saa pestä vain

vähintään 30 cm etäisyydeltä. Ohjeiden

vastaisesti käytettynä korkeapainesuihku

voi vahingoittaa renkaita/venttiilejä. En-

simmäinen merkki tästä on renkaan vär-

jäytyminen. Vaurioituneet auton renkaat/

venttiilit saattavat olla hengenvaarallisia.

EHUOMIO: Korkeapaineella tuleva vesisuih-

ku voi olla vaarallinen, jos sitä käytetään

epäasianmukaisesti. Älä koskaan kohdista

suihkua henkilöitä, eläimiä, päällekytket-

tyjä sähkölaitteita tai laitetta itseään koh-

den.

EHUOMIO: Korkeapaineletkut, lisätar-

vikkeet ja liitännät ovat tärkeitä laitteen

turvallisuutta varten. Käytä ainoastaan

valmistajan hyväksymiä letkuja, lisätarvik-

keita ja liitäntöjä (on erittäin tärkeää, että

nämä osat pysyvät ehjinä, vältä tämän

vuoksi epäasianmukaista käyttöä ja suojaa

ne taitteilta, iskuilta ja naarmuuntumisel-

ta).

EHUOMIO: Pesukahva on varustettu turva-

lukolla. On tärkeää, että tätä turvalukkoa

käytetään joka kerta, kun laitteen käyttö

keskeytetään, jotta sattumanvarainen

avautuminen estettäisiin.

- Älä kohdista suihkua itseäsi tai muita hen-

kilöitä kohden, puhdistaaksesi kenkiä tai

vaatteita.

- Lapset tai kouluttamattomat henkilöt ei-

vät saa käyttää laitetta.

- Turvalaitteet: Pesukahva turvalukon kans-

sa, kone on varustettu ylikuormitussuojal-

la (luokka 1), pumppu on varustettu ohi-

tusventtiilillä tai pysäytyslaitteella.

- Pesukahvan turvapainikkeella ei lukita vi-

pua käytön aikana, vaan ettei se avaudu

sattumanvaraisesti.

EHUOMIO: Laitteet ilman A.S.S.-järjestel-

mää – Automatic Stop System (automaat-

tinen pysäytysjärjestelmä): ne eivät pesu-

kahvan ollessa vapautettuna saa toimia yli

2 minuuttia. Kiertopiiriin syötetyn veden

lämpötila kohoaa huomattavasti ja aiheut-

taa pumpulle vakavia vaurioita.

EHUOMIO: Laitteet A.S.S.-järjestelmän

kanssa – Automatic Stop System (auto-

maattinen pysäytysjärjestelmä): laitetta ei

tulisi jättää valmiustilaan (stand-by) yli 5

minuutiksi.

EHUOMIO: Kytke ilman valvontaa jäävä lai

81

FI

pumpun maksimaaliseen virtaamaan nähden

kaksinkertainen vedenanto.

Minimivirtaama: 30 l/ min.-

Maksimaalinen vedenlämpötila sisään--

menossa: 40°C

Maksimaalinen vedenpaine sisäänmenos--

sa: 1Mpa

Aseta korkeapainepesuri mahdollisimman lä-

helle vedenjakeluverkkoa.

Vedenotto vesijohdosta

t-JJUÊWFEFOTZÚUUÚMFULVFJLVVMVVWBSVTUVL-

siin) laitteessa olevaan vesiliittimeen (kuva

6, kohta 1) ja vesijohtoon (paine max. 10

baaria).

t-JJUÊQBJOFQVULJVMPTUVMPMFULVVOLVWBkohta 2) ja avaa vesihana.

Korkeapainepesuri voidaan liittää suoraan julki-

seen vesijohtoverkostoon jos syöttöputkistoon

on asennettu virtauksenestolaite tyhjennyk-

sellä voimassa olevien määräysten mukaisesti.

Varmista, että putki on halkaisijaltaan vähin-

tään 13mm ja vahvistettu.

Kyseisten ehtojen noudattamatta jättäminen

saa aikaan vakavia mekaanisia vahinkoja pum-

pulle takuun raukeamisen ohella.

> KORKEAPAINEPUTKI

EHUOMIO: Korkeapaineputki on suunnitel-

tu ja valmistettu kestämään korkeata pai-

netta. Jotta se ei vahingoittuisi, sitä tulee

käsitellä varovaisesti.

Väärä käyttö voi aiheuttaa vahinkoa tai ennen-

aikaista rikkoutumista ja aiheuttaa takuun voi-

massaolon lakkaamisen (ks. kuvat).

> SÄHKÖNSYÖTTÖ

- Laitteen sähköliitännän täytyy olla normin

IEC 364 mukainen.

Varmista ennen laitteen liittämistä, että

tyyppikilven tiedot vastaavat sähköverkon

arvoja ja että pistorasia on suojattu vika-

virtasuojakytkimellä, jonka kytkeytymis-

herkkyys on alle 0,03 A - 30ms.

- Mikäli pistoke ei sovi pistorasiaan, anna

te joka kerta täysin pois päältä (pääkytkin asen-

toon OFF).

EHUOMIO: Jokaiselle koneelle suoritetaan

lopputarkastus käyttöolosuhteissa, joten

on normaalia, että laitteen sisällä on vielä

muutamia vesipisaroita.

EHUOMIO: Huomioi, että virtajohto ei vau-

rioidu. Anna valtuutetun asiakaspalvelun/

sähköalan ammattiliikkeen vaihtaa välittö-

mästi vaurioitunut liitäntäjohto.

EHUOMIO: Laite sisältää paineenalaisia

nesteitä. Pidä lujasti kiinni pesukahvasta,

jotta reaktiovoima estettäisiin. Käytä lai-

tetta vain mukana tulevan korkeapai- ne-

suuttimen kanssa.

EHUOMIO: Korkeapaineletku on kehitetty

ja valmistettu siten, että se kestää korkeita

paineita. Vaurioiden välttämiseksi täytyy

sitä käyttää erityisen varovasti. Epäasian-

mukainen käyttö voi aiheuttaa ennenai-

kaisia vaurioita tai murtumia sekä takuun

raukeamisen.

EHUOMIO: Lapset tai fyysisesti tai henki-

sesti rajoittuneet henkilöt tai henkilöt, joil-

la ei ole laitteen käyttöön vaadittavaa ko-

kemusta tai tuntemusta eivät saa käyttää

laitetta, kunnes he eivät ole saaneet siihen

vaadittavaa koulutusta tai opastusta.

EHUOMIO: Lapset eivät saa leikkiä laitteel-

la, vaikka heitä valvotaan.

EHUOMIO: Käynnistä painepesuri vasta sen

jälkeen, kun olet kelannut korkeapainelet-

kun auki.

EHUOMIO: Varmista, ettei painepesuri pää-

se kaatumaan kumoon letkun kiinni/ auki-

kelaamisen yhteydessä.

EHUOMIO: Varmista ennen letkun kiinni/

aukikelaamisen aloittamista, että painepe-

suri on sammutettuna ja ettei letkussa ole

painetta (ei käytössä).

> VEDENSYÖTTÖ

7FTJMJJUÊOUÊ)VPNJP7BBSBIme pelkästään suodatettua tai puhdasta vet-

tä. Vedenottoon tarkoitetun hanan on taattava

This manual suits for next models

17

Table of contents

Languages:

Other LavorPro Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Kärcher

Kärcher G 3050 OH Operator's manual

Weidner

Weidner Waschbar SE 112 Operating manual / spare parts list

Kärcher

Kärcher HDS 12/14-4 ST Gas instructions

Power

Power APW3200KH Owner's Manual and Operating Instructions

Alto

Alto Speed 4050 X-TRA Repair manual

Kärcher

Kärcher HDS 7/9-4 M Original instructions