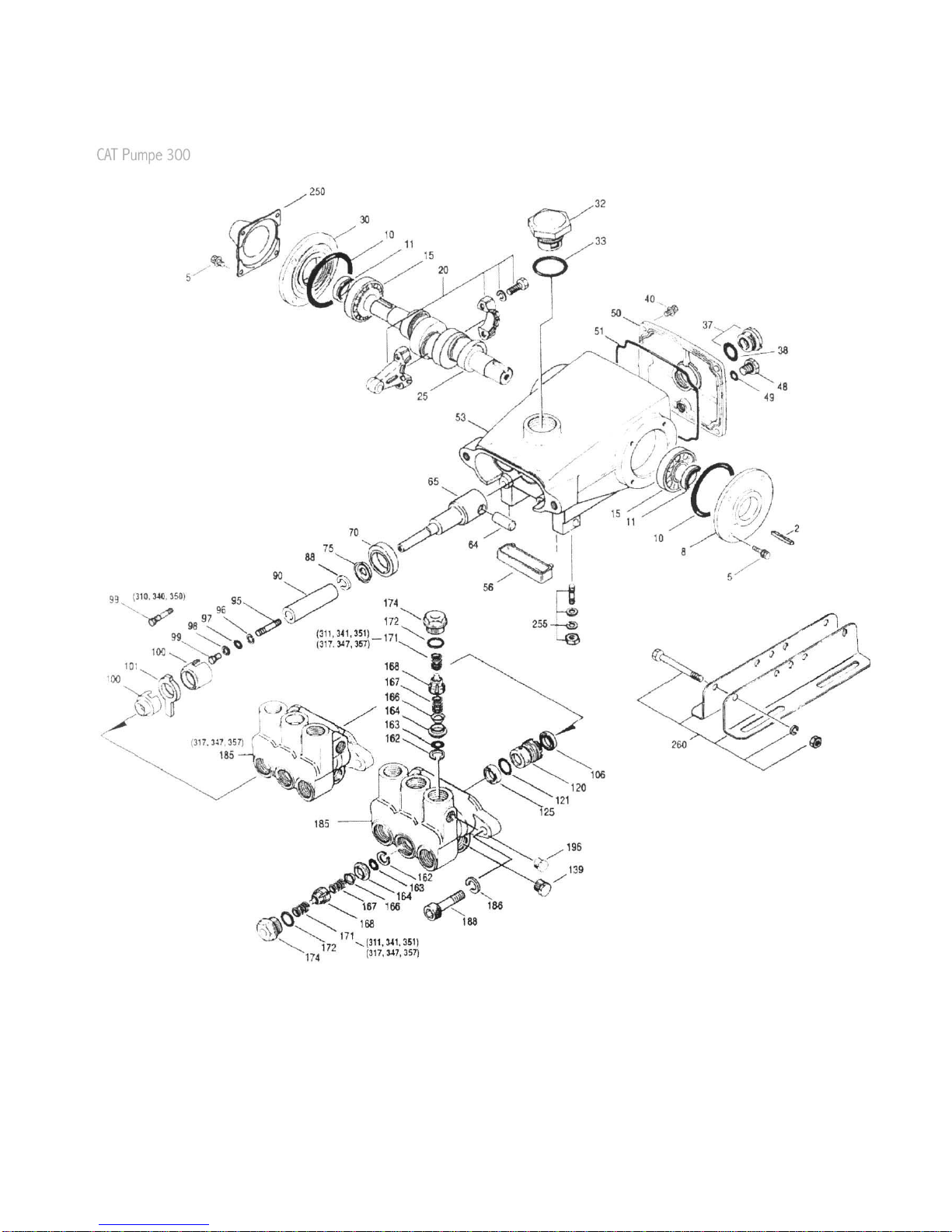

Pos. No. Bezeichnung Description

2 3851502700 1 Passfeder parallel key

5 3851502745 8 Schraube screw

8 EPACA43344 halb Lagerdeckel quill

10 EPACA43343 2 O-Ring Lagerdeckel o-ring quill

11 EPACA43222 halb Simmering simmering

15 EPACA014480 2 Lager camp

20 EPACA043345 3 Pleuel, kompl. piston rod

25 EPACA044923 1 Kurbelwelle crankshaft

30 EPACA044949 1 Hauptschalter für Bodenbefestigunng main switch for soil attachment

32 EPACA043211 1 Verschluß (Öleinfüllstutzen)catch

33 EPACA014177 1 O-Ring Verschluß o-ring catch

37 EPACA043987 1 Ölschauglas

38 EPACA044428 1 Flachdichtung gasket

40 EPACA092520 4 Schraube screw

48 EPACA025625 1 Ölablaßschraube oil drain plug

49 EPACA023170 1 O-Ring, Ablaßschraube o-ring,

50 EPACA043339 1 Gehäusedeckel discharge screw

51 EPACA043340 1 O-Ring, Gehäusedeckel o-ring, fram cover

53 EPACA043338 1 Kurbelgehäuse crank case

56 EPACA043355 1 Ölwanne oil pan

64 EPACA043351 3 Bolzen pin

65 EPACA43365 3 Plungerstange plunger seaweeds

70 EPACA043228 3 Simmerring Buna-N simmering

75 3851502778 3 Stauscheibe pilot disk

88 EPACA045697 3 Scheibe disk

90 EPACA043367 3 Keramikplunger creamics plunger

96 EPACA043235 3 Stützring, Plungerhalter back-up ring

97 EPACA017399 3 O-Ring, Plungerhalter o-ring, plunger owner

98 EPACA045891 3 Scheibe disk

99 EPACA104360 3 Plungerhalter plunger owner

100 EPACA0456812 3 Dichtungshalter kmpl. seal owner

101 EPACA043302 3 Ölfilz oil felt

106 EPACA043305 3 ND-Dichtung ND-seal

120 EPACA045679 3 Dichtungsgehäuse seal housing

121 EPACA014200 3 O-Ring, Dichtungsgehäuse.Buna-N o-ring, seal housing

121A EPACA011719 3 O-Ring, Dichtungsgehäuse, Viton o-ring, seal housing

125 EPACA046667 3 HD-Dichtung, Buna-N HD-seal

125A 3851502811 3 HD-Dichtung, Viton HD-seal

139 EPACA022179 1 Stopfen, Einlaß 1/2" plug inlet

162 EPACA043357 6 Stützring back up ring

163 EPACA043358 6 O-Ring, Ventilsitz Buna-N o-ring, valve seat

163A EPACA044938 6 O-Ring, Ventilsitz Viton o-ring, valve seat

164 EPACA030821 6 Ventilsitz valve seat

166 EPACA030821 6 Ventil valve

167 3851502832 6 Ventilfeder vale spring

168 EPACA044565 6 Federhalter Ventil penholder valve

172 EPACA017615 6 O-Ring Ventilst. Buna-N o-ring valve Buna-N

172A EPACA015855 6 O-Ring Viton o-ring Viton

174 EPACA043849 6 Ventilstopfen valve pot

185 EPACA044837 1 Pumpenkopf pumping head

186 EPACA012503 2 Federring lock washer

188 EPACA087931 2 Schraube M10x35 screw M10x35

250 803118672 1 Wellenschutzkappe waving protective cap

299 EPACA810027 1 Pumpenkopf komplett pump head cmpl.

350 EPACA030696 1 Werkzeug (Ventilsitz) tool (valve seat)

351 EPACA035104 1 Werkzeug (Dichtungsgehäuse) tool (seal housing)

300* EPACA033623 1 Dichtungssatz STG, enthält Nr.97; 101; 106; 121; 125 gasket kit