Operation

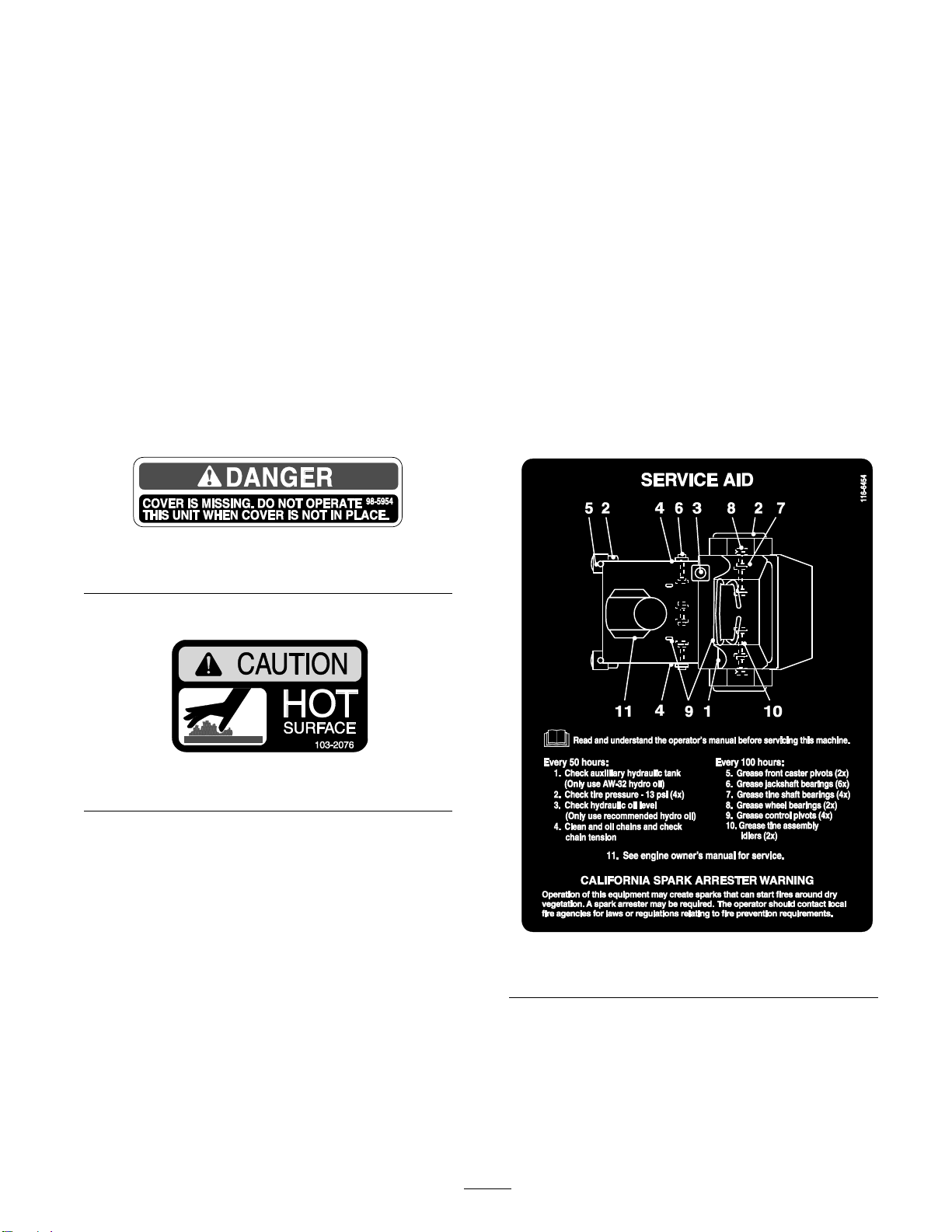

Operating engine parts, especially the muffler,

become extremely hot. Severe burns can occur

on contact and debris, such as leaves, grass,

brush, etc. can catch fire.

Allow engine parts, especially the muffler,

to cool before touching.

Remove accumulated debris from muffler

and engine area.

Install and maintain in working order a

spark arrester before using equipment on

forest-covered, grass-covered, or brush-

covered unimproved land.

Engine exhaust contains carbon monoxide,

which is an odorless deadly poison that can

kill you.

Do Not run engine indoors or in a small

confined area where dangerous carbon

monoxide fumes can collect.

Operate only in daylight or good artificial

light, keeping away from holes and hidden

hazards.

Be sure all drives are in neutral and parking

brake is engage before starting engine.

Never operate the machine with damaged

guards, shields, or covers. Always have safety

shields, guards, switches and other devices in

place and in proper working condition.

Do Not change the engine governor setting or

overspeed the engine.

Park machine on level ground. Stop engine,

wait for all moving parts to stop, remove key

and engage parking brake:

-Before checking, cleaning or working on

the machine.

-After striking a foreign object or abnormal

vibration occurs (inspect the machine for

damage and make repairs before restarting

and operating the machine).

-Before clearing blockages.

-Whenever you leave the machine.

Stop engine, wait for all moving parts to stop,

and engage parking brake:

-Before refueling.

Hands, feet, hair, clothing, or accessories

can become entangled in rotating parts.

Contact with the rotating parts can cause

traumatic amputation or severe lacerations.

Do Not operate the machine without

guards, shields, and safety devices in

place and working properly.

Keep hands, feet, hair, jewelry, or

clothing away from rotating parts.

NEVER carry passengers. DO NOT operate

the machine when people, especially children,

or pets are in the area.

Be alert, slow down and use caution when

making turns. Look behind and to the side

before changing directions.

Raise the tines, slow down, and use caution

when crossing surfaces other than grass and

when transporting the machine to and from the

work area.

Do Not operate the machine under the

influence of alcohol or drugs.

Use extreme care when loading or unloading

the machine into a trailer or truck.

Use care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

Slope Operation

Use Extreme caution when aerating and/or

turning on slopes as loss of traction and/or tip-

over could occur. The operator is responsible for

safe operation on slopes.