Ldsolar TRACER DREAM Series User manual

Tracer Dream series

User’s manual

of MPPT solar charge controller

MAX PV Input voltage 150V

12V/24V/48V 50A 60A

Dear Users:

Thank you for selecting our product. Please read this manual carefully

before you use this product.

Safety Tips

The input voltage of this controller is high, non-standard operation will

cause great damage to user. Please read this manual carefully and finish

the safety operation regulation before using this controller.

Please read all product safety caution and operation instruction carefully in this manual.

There are no components inside the controller that require maintenance or repair, users

are not allowed to disassemble and repair the controller by themselves.

It is better to install controller in the room, if install the controller outside, please keep

the environment dry, avoid direct sunlight and waterproof well.

Please install the controller in a well ventilated place, the heat sink temperature is very

high in process of working.

It is recommended to install suitable fuse or circuit breaker in front of controller.

Before installing and adjusting the wiring of the controller, be sure to disconnect the

wiring of the photovoltaic array and the fuse or circuit breaker near the battery terminal.

After installation, please check that all wiring connection are tight to avoid heat

accumulation due to loose connection.

Features:

This series of product adopt synchronous rectification technology and common negative design, and

equipped with LCD. The advanced MPPT control algorithm can quickly and accurately track the maximum

power point of photovoltaic array in any environment, obtain the maximum energy of solar panel in real time,

and improve the energy utilization of solar energy system. It can be used in communication base station,

household system, street light system and monitoring system and so on. Perfect electronic protection function

and patent terminal structure can avoid the damage of components and due to system fault and installation

error.

Advanced MPPT technology, fast and stable track the Maximum Power Point, tracking accuracy 99.5%.

Adopt Synchronous Rectification Technology, significantly improve the transfer efficiency of circuit,

maximum 98%.

With double peak or multi peak power tracking technology, when the solar panels is shaded or part of

solar panels is damaged, multiple peaks will appear in the I-V curve, and the controller can still accurately

track to the maximum power point.

PV array limited input power function, to ensure that the controller dose not overload operation under

any condition. When the power of solar panels is too high and the charging current is more than rated

current, the controller automatically reduces the charging power to make it work under the rated power.

Wide range of Maximum Power Point of PV array, Max PV input voltage 150V

12/24V/48VDC System voltage automatic recognition.

Humanized LCD displaying, multi button combination operation, dynamic display operation data and

working state

Built-in operation log, account system working state

Multi load control mode: Normal Mode, Sensor Mode, Timer and Sensor Mode

3 stages charging mode, Sealed, Gel, Flooded, Lithium several types battery charging procedure selection

(After the lithium battery is selected, the system voltage will not be recognized automatically)

Temperature Compensation Function(After the lithium battery is selected, there is no temperature

compensation function).

Accumulation function of charging and discharging, actual time display power generation function.

Fullest digital protection functions: Reverse connection, Overcharging, Over-discharging, Over voltage,

Overload, Short circuit, Overtemperature.

25mm2connectors, red and black connector distinguish plus and minus.

Using standard Modbus communication protocol based on RS-485 communication bus, maximize

satisfaction different occasions communication need.

Optional Blue-tooth or WiFi communication module, through the mobile phone APP can view and set the

parameters of the controller in real time.

Product Feature

No.

Name

No.

Name

1

Charging Status Indicator

7

Battery negative

2

with backlight LCD

8

Battery positive

3

Button Operation area

9

RS485 interface①

4

Mounting hole

10

External temperature interface②

5

PV positive

11

Dry contact③

6

PV negative

12

radiator

1Connect PC or expand Bluetooth WIFI module

2Connect external temperature sensor to sample battery temperature data.

3Switch for controlling battery electrical equipment according to the voltage value of battery. (Main for Inverter, Later, it

may be changed to normally open or normally closed)

Description of accessories

1

External

Temperature

Sensor

(Standard

Configuration)

The battery temperature data is collected to accurately adjust the

charging and discharging parameters as temperature compensation. The

standard line length is 1.5 meters (it can also be customized according

to the user's needs), and it is connected through the interface 10. Note:

when the remote temperature sensor is not connected or the

temperature sensor is damaged, the controller will default to 25 ℃ to

charge or discharge the battery without temperature compensation.

2

USB to RS485

Communication

line(Optional)

Special cable for connecting controller communication interface (RJ45

interface) and USB interface of PC, the standard line length is 1.5 meters

(it can also be customized according to the user's needs). The controller

can be real-time monitored and parameters set by the special upper

computer software

3

Bluetooth

module

(Optional)

The controller and Bluetooth module are connected by standard

network cable (parallel line). The mobile app software can monitor and

set parameters of the controller in real time through Bluetooth signal.

4

WIFI module

(Optional)

The controller and WiFi module are connected by standard network

cable (parallel line). The mobile app software can monitor and set

parameters of the controller in real time through WiFi signal.

Installation of Instructions

1.

Safety Considerations

This controller is base on solar panel feature researching, if use other power supply instead of solar panel,

the controller may cause fault.

It is better to install controller in the room, if install the controller outside, please keep the environment dry,

avoid direct sunlight and waterproof well.

The controller will be hot in process of working, please keep the environment ventilation,

away from flammable.

Solar panels will produce high voltage when there is light. Do not touch or short circuit wires and

terminals. When operation is required, pay attention to dry hands, use insulating tools and stand on

dry ground.

Only lead acid or Lithium batteries that meet the control range of this controller can be charged. For special

batteries, please consult with technical personnel.

The battery contains acid electrolyte. Please wear goggles when installing. If you contact the electrolyte

carelessly, please wash it with clean water

The battery has huge power, forbid any conductor short circuit the positive and negative poles of battery.

Suggest to adding a fuse between battery and controller. (Slow motion type, the action current of the fuse

should be 1.5 times rated current of the controller)

Please install the controller in a place where children can not touch.

2.

Precautions for use

The controller could detect the temperature of environment to adjust the voltage of charging,

so that the controller should be closed to battery as near as possible.

Recommend system current density of cables less than 4A/mm2, Unreasonable cable selection will increase

the system consumption, even burning.

Try to use multi strand copper wire in order to connecting with the terminal firmly. Loose power connection

and/or corroded wires may result in resistive connections that melt wire insulation, burn surrounding

materials or even cause fire.

Please keep the battery full charged (one time each month at least), or the battery will be destroyed.

This product have limited solar panel input power function, in theory, no matter how much power of solar

panel input, the controller will limited the input power under rated power, but must pay attention to the

following two points:

1) The short circuit of solar panel less than rated current of controller.

2) The Open Circuit Voltage of solar panel increased with decreasing temperature, please ensure in any

case, the Open Circuit Voltage of solar panel array will not exceed 150V, otherwise it will trigger

protection or damage to the controller.

3.

PV module connection requirements

1) Number of PV module in series

Due to the different types of photovoltaic modules in the market, the controller, as the core component of

the photovoltaic system, can adapt to various types of photovoltaic modules and can maximize the

conversion of solar energy into electric energy. According to the open circuit voltage (VOC) and maximum

power point voltage (vmpp) of MPPT controller, the series number of photovoltaic modules suitable for

different types can be calculated. The following table is the number table of photovoltaic modules in series,

for reference only:

System

Voltage

36cell

Voc<23V

48cell

Voc<31V

54cell

Voc<34V

60cell

Voc<38V

72cell

Voc<46V

96cell

Voc<62V

Thin film

moduleV

oc>80V

Max

Best

Max

Best

Max

Best

Max

Best

Max

Best

Max

Best

12V

4

2

2

1

2

1

2

1

2

1

1

1

1

24V

6

3

4

2

4

2

3

2

3

2

2

1

1

48V

6

5

4

3

4

3

3

3

3

2

2

2

1

2) Maximum power of PV array

The MPPT controller has the function of limiting the input power, that is, the controller can limit the power or

charging current within the rated range of the controller, and the maximum power of the controller can not be

greater than the rated charging power of the controller If the input power exceeds the rated charging power of the

controller, the controller will charge the battery according to the rated charging power of the controller. The actual

operation power of PV array meets the following conditions:

When the actual operating power of the PV array is less than the rated charging power of the controller,

the controller operates at the maximum power point of the PV array.

If the power of the PV array is greater than the rated charging power of the controller, the operation

time at full power of the controller will be extended, so more energy can be obtained to charge the

battery.

Attention:When the input wiring of PV array is correct and the actual power is more than 2

times of the rated power of the controller, the controller may be damaged. When the input

of PV array is reversed and the current actual power is more than 1.5 times of the rated

power of the controller, the controller will be damaged.

4.Fixation of controller

1)

The controller should be installed well-ventilated place, avoid direct sunlight, high temperature and do

not install in location where water can enter the controller. If it is to be sealed installation, please ensure

that the box can be reliably cooled.

2)

Please select correct screw to fix the controller on the wall or other platform. Screw M4 or M5, Screw cap

diameter less than 10mm.

3)

Please reserve enough space between the wall and controller, at least 150 mm up and down to allow for

cooling and cable connection.

4)

The mounting holes distance is 176mm*226mm,diameter of hole is 5mm.

5)

Aluminum fins for natural cooling, we strong suggest hanging installation, this is better for air flow

cooling effect.

5.Controller Connection

Before connecting, make sure that the system voltage matches with the selected products, and

whether the open circuit voltage and maximum power of the PV array are within the reasonable

range of the controller.

The following order of connection please do not free change,The controller has the function of

automatic identification of battery voltage. The battery should be connected first, otherwise it

may cause system voltage identification error.

All terminals are in tight status after factory, in order to well connected, please loose all terminals

at first.

If there is a short circuit at the terminal of the controller, it may cause fire or explosion! Please

operate with caution! It is strongly recommended to add air switches or fuses between the

battery and the controller and between the solar panel and the controller, and disconnect all air

switches or fuses before wiring (the air switch or fuse shall be selected according to 1.5 ~ 2

times of the rated current of the controller)

In order to avoid fault installation, please refer to below procedure

1)

As shown in the figure, connect the positive wire of the battery to battery positive terminal of the

controller(terminal 8), and the negative wire to battery negative terminal of the controller(terminal 7). The

connecting wire between the battery and the controller shall be as short as possible, and the recommended

distance is between 30cm and 100cm.

2)

As shown in the figure, connect the positive wire of photovoltaic array to PV positive of the

controller(terminal 5), and the negative wire to PV negative of the controller(terminal 6).

3)

Insert the standard external temperature sensor of the controller into terminal 10 of the controller. The

controller collects the temperature of the battery through the temperature sensor to compensate the

charging voltage. The temperature sensor should be close to the battery and away from other heat

sources, otherwise, the controller will have wrong action.

Note: the interface of temperature sensor and exposed copper part of wire shall not contact any

other live conductor, otherwise the controller will be damaged

4)

The interface of dry contact is on terminal 11 of controller. If you want to control other equipment,

switch of other equipment can be introduced to dry contact, and the maximum control current of dry

contact shall not be more than 2A.

Note: if the plug of dry contact is connected to the port of temperature sensor, the controller will be

damaged.

5)

If you want to connect the controller with a PC, you need a special RS485 communication

option. One end is RJ45 interface, which is connected to terminal 9 of the controller, and the

other end is USB interface, which is connected to the computer.

6)

If you want to connect the controller with the mobile phone app, you need a special WiFi or

Bluetooth communication option. One end is RJ45 interface, which is connected to terminal 9 of

the controller to communicate with the mobile phone through wireless signal.

For details of software use, please refer to the 《controller monitoring software operation manual》

6.Start Controller

Note: the controller supports starting the controller from the photovoltaic array end. When the

automatic battery identification function is selected, starting the photovoltaic array terminal first

may make the controller identify the system voltage error.

Before connecting the power supply, please confirm whether the wiring of battery terminal and

photovoltaic array terminal is correct.

After confirming that there is no error, first close the air switch or fuse at the battery end, so that the

controller can recognize the system voltage, and observe whether the LCD is on and whether the

interface is correct. If there is display or alarm status, please refer to 《Fault and Handling》 for

troubleshooting, and then carry out the following operation.

After the battery is connected normally, close the air switch or fuse at the photovoltaic array end. If the sunlight

is sufficient, the charging indicator light of the controller will flash, and the LCD interface will display the charging

state and photovoltaic array voltage, and start charging the battery. When disconnecting the system, please

disconnect the photovoltaic array first and then the battery.

7.

Grounding of solar system

Please bear in mind that this type of controller is a common negative design. Therefore, the

negative terminal of battery end and photovoltaic array end in the controller are connected

together. If the solar system needs to be grounded, you can choose any negative grounding!

8.

About LCD backlight

If no key is pressed, the LCD backlight will turn off automatically after 15s. When any key is

pressed, the LCD backlight will turn on again.

Battery Charging Process The controller has a three-stage charging mode, namely bulk charging, boost charging and float charging. Through these fast, efficient and safe battery charging methods, the service life of the battery can be

effectively extended.

Bulk Charging : Fast charging stage, the voltage of

battery is not reach to full charged set point. (Float

point or Boost point), the controller will be work at

MPPT mode. In process of Maximum Power of solar

panel charging.

Boost Charging : Each time the battery voltage less

than 12.6V, the controller will auto boost charging one

time. When the boost voltage reach to set point, the

controller will join into constant voltage charging

mode instead of MPPT mode, and gradually reduce the charging current, the boost charging continued

2H then go to float charging mode. (Due to the load capacity and generated changing, the controller

can't keep constant voltage charging, the constant voltage charging time will be accumulated,

accumulate 2hours cancel boost charging mode.

Float Charging :

After entering the floating charging mode, the controller will reduce the charging current

and charge weakly to maintain the battery at the floating charge voltage value. (if the voltage is not lower

than 12.6V, the boost charging mode will not be started, only floating charging will be carried out)

Main Interface

Name

Symbol

Indicate function

Solar Panel

Correct connect solar panel and in daytime

No connect solar panel or wrong connection

or at night

MPPT mode charging

Float charging mode

Boost charging mode

no charging

Data about charging

Battery capacity indicating

12V24V48V

Present System Voltage Show

Battery

Data about battery

Battery Type

Dry

Contact

Dry contact ON

Dry contact OFF

Dry contact Sensor and Timer mode output

Dry contact Sensor mode output

LOAD

Data about Dry contact

Dry contact working mode

Operation and Indication of controller

Main Interface

If no operation at main interface inner 10s, the main interface will cycle show battery voltage, PV array

voltage, charging current, battery type, temperature of environment, each parameter keep 3s.Long press “▲”

or “▼”button could speed loop display.

At the main interface short press “OK” button could on or off the Dry contact.

At the main interface long press “MENU” and “▲”5S could show work log, short press “▲”or“▼”

could see times of LVD, working days, times of over current protection, time of HVD. Press ”↺” could

return to main interface.

At main interface press “MENU” button could enter into menu interface. Press”↺” to exit from

any interface

At the menu interface press “▲”or“▼” could see the parameter, when reaching any parameter that can

be set, press “OK” button to enter the parameter setting state, press “▲” or“▼” could adjust the

value of the parameter. Long press “OK” button for 5s to save the setting data and exit the setting state

or press “↺” to exit without saving.

1)

PV power:This interface show the solar panels current output power.

2)

Accumulated Charging Power(AH): account current system generation ampere hour, long press “↺”button

could zero clearing.

3)

Float Voltage:

When the voltage of battery reach to this set point, the controller will start constant voltage charging

mode, limited the rising of battery voltage, decrease the charging current to keep the battery in full condition.

4)

Boost Voltage:When the battery voltage less than 12.6V, the HVD auto reach to 14.4V at the same time keep 2hours

then back to float voltage.

5)

Dry contact Low Voltage Reconnection(LVR) Voltage :

When the controller detected and closed the output of

load. If the controller is reconnect the output, the voltage of battery must be higher than LVR voltage or press “OK”

at main interface force to release.

6)

Dry contact Low Voltage Disconnection(LVD) Voltage :

When the voltage of battery is low, the load output

will be cut off. When the controller detected the battery voltage was less than LVD point, the cut off function will be

immediately working. At the same time, the status of controller is in lock. Users have to charge the battery, when the

battery voltage is higher than LVD voltage or press “ OK ” at main interface force to release, the dry contact will

resume power supply again.

7)

Dry contact Load mode:The control default load working 24hours. When the Load Working Time set to 24hours, the

load will keep working 24hours in no fault status. When the load working time set to ≤23H, it means the load start timer

or sensor function. If the battery capacity is enough, the load will be started at sunset. The load will work under timer

setting hours or stop working till sunrise.

8)

Temperature Detection inside controller : When the inside temperature of controller more than 75 ℃ , the

charging current will be down, exceed 85℃ closed charging.

9)

Battery Type Selection : Program Built-in 5 types battery data. Different battery will use different parameter.

(Default SEL battery parameter)

Note: for the control parameters related to the battery, we have fully considered the user's actual use.

If you want to modify, please refer to the battery supplier's suggestions, otherwise setting

unreasonable parameters will damage the battery. For lithium battery control parameters, please

adjust according to the battery supplier's recommendations.

Battery Type

SEL

GEL

FLD

Lithium iron phosphate battery

12V4 series LF4/24V8

seriesLF8/48V16 seriesLF16

Ternary lithium battery 12V3

seriesLI3/24V6

seriesLI6/48V12 seriesLI12

Over voltage protection

voltage

16.0V

16.0V

16.0V

16.0V

17.0V

Charging limit voltage

15.0V

15.0V

15.0V

14.8V

17.0V

Over voltage

reconnection voltage

15.0V

15.0V

15.0V

14.8V

17.0V

Boost voltage

14.4V

14.2V

14.6V

14.6V

12.6V

Float voltage

13.8V

13.8V

13.8V

14.2V

12.3V

Boost recovery voltage

12.6V

12.6V

12.6V

13.0V

11.5V

LVD recovery voltage

12.6V

12.6V

12.6V

12.6V

11.0V

LVD voltage

11.0V

11.0V

11.0V

10.5V

8.5V

Note: when the system is set to lithium battery type, the temperature compensation is zero and the

system will not be able to complete the automatic identification of battery voltage. After setting the type

of lithium battery, the system should be powered off completely and then powered on again to initialize the

system voltage.

Protection Function

Fault Symbol Indication

State

Symbol

Condition

LVD Protection

Battery empty and Warning Flash together

Battery Over Voltage Protection

Battery full and Warning Flash together

Controller Over Temperature

Protection

Temperature symbol and Warning Flash together

Solar Panel Over Voltage

Protection

Solar Panel symbol and Warning Flash together

The indicator lights flash

Normal charging

The indicator gradually on and off

PV voltage low can not start charging

The indicator off

Stop charging

Short Circuit and Reverse Connected Protection (Solar Panel)

When the solar panels have short circuit or reverse connection, the controller will be off the charging immediately, after

clearing of the short circuit, the charging will be automatically feedback.

Solar Panel Over Voltage Protection

When the input voltage from solar panel more than 150V, the controller will be off immediately, after input voltage

less than 145V the controller will be auto restart charging.

Reverse Connection of battery Protection

If the battery reverse connection, the controller will not destroy, corrected the connection the controller

will be normally working.

Note: since the controller can be started from the photovoltaic array end, the controller will be

damaged when the photovoltaic array is connected right and the battery end is reversed.

Battery Over Voltage Protection

When the battery voltage reaches the over-voltage cut-off point, the controller will automatically stop

charging and discharging the battery to prevent the battery and load from being damaged by the high

voltage of the battery.

Battery Low Voltage Protection (LVD)

When the voltage of battery was reach to LVD (Low Voltage Disconnection) point, the controller will be

auto closed the output in order to avoid over-discharge the battery.

Photovoltaic array over power protection

If the power of photovoltaic array exceeds the rated value of the controller, the controller can limit the

power or charging current to be within the rated range of the controller, so as to ensure that the controller

will not operate excessively.

Over Temperature Protection

When the internal temperature of the controller exceeds 75 ℃, the controller starts to alarm and reduce the charging

current. The temperature and warning flash. When the temperature exceeds 85 ℃, the charging is stopped. When the

temperature drops to 65 ℃, it will resume normal operation.

Lightning Protection

This product could only protect small lightning induction, we suggest users to use lightning rod at frequency area.

Fault and Handling

Fault Phenomenon

Possible reason

Solution

LCD no display after connected with

battery

Battery Low

Battery Reverse Connection

The connection cut off

Please confirm the voltage of battery reconnect

the controller with battery firmly and correctly.

Full of sunshine vertical on solar panel,

no solar symbol and no charging symbol

on LCD.

The solar panel connection open

circuit, short circuit, or reverse

connected

Please check the cable of solar panels if they are

correct connection and firmly.

The controller displaying LVD

The battery is over discharging

Please check the system design is reasonable or

not. Please full charge the battery

The controller displaying Over Voltage

Protection of battery

The voltage of battery is too high

Please first cut off the solar panel and see if the

voltage get down normal level. If the fault do

not finish, please cut off the battery with

controller and reconnect again

Technical Data

Mode

TD4515TU

TD4615TU

System Voltage

12V/24V/48V Auto

PV Max input voltage

At minimum ambient temperature 150V(+25℃ ambient temperature

138V)

PV Max input power

12V 660W;24V 1320W;48V 2640W

12V 800W;24V 1600W;48V 3200W

MPPT Voltage range

(VBAT+2V)---120V

MPPT tracking accuracy

≥99.5%

Controller conversion efficiency

Max 98%

MPPT limited Power Output

Yes

Self-consumption

≤2W

Max Charging current

50A

60A

LVD

11.0V ADJ 9V….12V;×2/24V;×4/48V

LVR

12.6V ADJ 11V….13.5V;×2/24V;×4/48V

Float voltage

13.8V ADJ 13V….15V;×2/24V;;×4/48V

Boost voltage

14.4V ; ×2/24;×4/48V Battery Voltage less than 12.6V Start Boost2hours(Li-battery no)

Battery Over Voltage Protection

16.5V ;×2/24V;×4/48V

Reverse Connection Protection

YES

Controller Over Temperature

Protection

Yes,75℃ Start decrease charging current,85℃stop charging,65℃return to work

Charging Type

MPPT (It can support solar panel end start-up system)

Charge Control mode

3 stage:Bulk(MPPT),Boost,Float

Optional battery types

Lead Acid, Flood, Gel, Lithium iron phosphate, Ternary lithium battery

Temperature Compensation

-24 mV /℃ for 12V ;×2/24V;×2/24V;×4/48V(Li-battery no compensation)

Cooling mode

Natural heat dissipation of radiator

Working Temperature

-20℃---+50℃

Terminals scale

25mm2

25mm2

Waterproof grade

IP32

Size

277mm×243.8 mm×110.9mm

277mm×243.8 mm×110.9mm

Net weight

4.2KG

4.5KG

*If the controller operates in high temperature environment, please reduce the rating

Version No.:V202001

Appendix一 Mechanical dimension drawing Uunit(mm)

This manual suits for next models

3

Table of contents

Other Ldsolar Controllers manuals

Popular Controllers manuals by other brands

SMC Networks

SMC Networks LC8-B*H*-M*-Q Series Installation and maintenance manual

Burda

Burda BHC4002-ER Installation & user manual

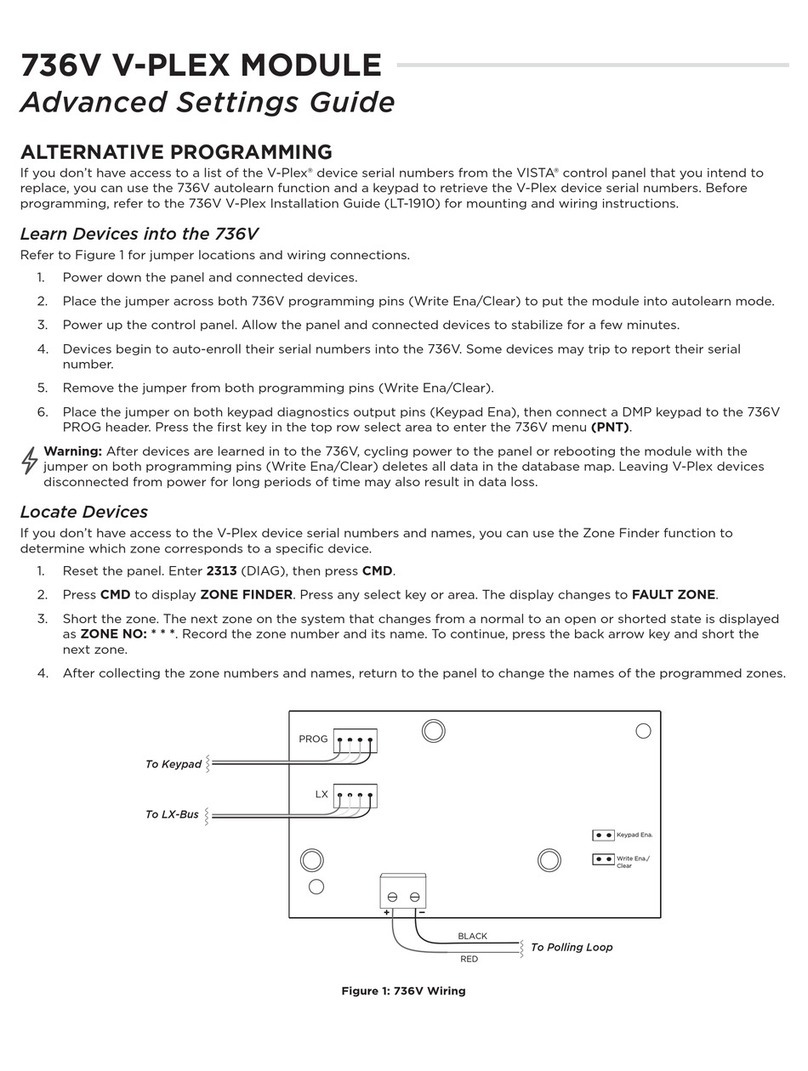

DMP Electronics

DMP Electronics 736V V-PLEX Module Advanced Settings Guide

SmartieParts

SmartieParts 9x installation instructions

Contro l4

Contro l4 C4-EA3-V2 installation guide

Regin

Regin RVAZ4-230 Instruction