Leader Electronics Corp. LT 416 User manual

LT 416

INSTRUCTION MANUAL

NTSC/PAL/SECAM

PATTERN GENERATOR

TABLE OF CONTENTS

GENERAL SAFETY SUMMARY ···························································································· |

1. INTRODUCTION ··············································································································1-1

1.1 Scope of Warranty ······························································································1-2

1.2 Operating Precautions ·······················································································1-2

1.2.1 Line Voltage and Fuse ························································································1-2

1.2.2 Reverse Voltage···································································································1-2

1.2.3 Installation ···········································································································1-2

1.2.4 Mechanical Shock ·······························································································1-3

1.2.5 Calibration ···········································································································1-3

1.2.6 Routine Maintenance··························································································1-3

2. SPECIFICATIONS ············································································································2-1

2.1 GENERAL ············································································································2-1

2.2 FEATURES ···········································································································2-1

2.3 Specifications······································································································2-2

2.3.1 Composite Video Signal Output ········································································2-2

2.3.2 Sync Signal··········································································································2-3

2.3.3 Test Patterns········································································································2-4

2.3.4 Y/ C Separation Output·······················································································2-5

2.3.5 Y, B-Y, R-Y Output ·······························································································2-5

2.3.6 R, G, B Output ·····································································································2-6

2.3.7 RF Output·············································································································2-6

2.3.8 Sound Output ······································································································2-7

2.3.9 General Specifications ·······················································································2-7

3. PANEL DESCRIPTION ····································································································3-1

3.1 Front Panel ··········································································································3-1

3.2 Rear Panel············································································································3-3

4. OPERATING PROCEDURE·····························································································4-1

4.1 Turning Power On ·······························································································4-1

4.1.1 Connecting Power Plug······················································································4-1

4.1.2 Turning Power On ·······························································································4-1

4.1.3 Warm-Up Time·····································································································4-1

4.2 Connection ··········································································································4-1

4.2.1 Cable ····················································································································4-1

4.2.2 Termination··········································································································4-2

4.3 Color System Selection······················································································4-2

4.4 Composite Video Signal·····················································································4-3

4.4.1 Variable VIDEO OUTPUT connector·································································4-3

4.4.2 Fixed VIDEO OUTPUT Connector······································································4-3

4.5 Component Video Signal····················································································4-3

4.5.1 Y, B-Y, R-Y Connectors ⑲··················································································4-3

4.5.2 R, G, B, C.SYNC Connectors ⑳·········································································4-3

4.6 Y/C Separation Signal·························································································4-4

4.6.1 Y/C OUTPUT Connector ·····················································································4-4

4.7 Audio Signal ········································································································4-4

4.7.1 AUDIO OUTPUT Connector················································································4-4

4.8 RF Signal ·············································································································4-4

4.8.1 OUTPUT Connector ⑱························································································4-4

4.8.2 Level knob ···········································································································4-4

4.9 Pattern Settings···································································································4-4

4.10 RF Channel Settings···························································································4-5

4.10.1 Setting Method ····································································································4-5

4.10.2 Setting Procedure ·······························································································4-6

4.10.3 Selecting Channel·······························································································4-7

4.10.4 Restriction by 「SYSTEM ⑨」············································································4-7

4.10.5 RF Modulation ·····································································································4-7

4.10.6 RF Setting Example ····························································································4-8

4.10.7 Sound Subcarrier Level Selection·····································································4-8

4.11 Battery Backup····································································································4-9

4.11.1 Backup Capability ·······························································································4-9

4.11.2 Battery··················································································································4-9

4.11.3 Battery Life ··········································································································4-9

4.12 Fuse Replacement ······························································································4-9

5. RF CHANNEL PLAN········································································································5-1

5.1 Broadcast System·······························································································5-1

5.2 Broadcast System/Channel Plan for Country/ Region ····································5-1

5.3 Channel Plan Table ·····························································································5-7

5.3.1 How to use Channel Plan Table ·········································································5-7

5.3.2 Channel Plan Table ·····························································································5-8

6. MAINTENANCE ···············································································································5-20

— I —

The sections where this symbol is marked in this manual or

instrument, if not correctly performed or practiced, could result in

personal injury or cause serious danger to the instrument. Misuse

could also produce unintentional movement to create an

operational impediment on the instrument or other products that

might be connected to it.

Be sure to refer to the safety precautions in this manual to safely

use the part of the instrument where the symbol is marked.

Warning statements identify warning conditions that if

disregarded

or not correctly performed or adhered to, could result in serious

personal injury or even loss of life.

Caution statements identify caution conditions that if disregarded

or not correctly performed or adhered to, could result in personal

injury or damage to the instrument.

<Symbol>

<Te r m >

<Te r m >

WARNING

CAUTION

GENERAL SAFETY SUMMARY

■To Avoid Personal Injury

It is recommended that only qualified personnel with technical knowledge use this

instrument only after reading and fully understanding all functions of the instrument

described this instruction manual.

This instrument is not designed and manufactured for consumers.

If you do not have enough knowledge on electricity, to avoid personal injury and

prevent damage to this product, please be sure to use this product only under the su-

pervision of an engineer who has sufficient knowledge about electronics.

■Precautions on Contents

Should you find the contents in this manual and any of its technical terms confusing,

please feel free to contact your local LEADER agent.

■Symbols and Terms

Following terms and symbols indicate necessary warnings and cautions used in this

manual and on the product are there for safe operation.

— II —

WARNING

GENERAL SAFETY SUMMARY

Review the following safety precautions to avoid operator's injury and loss of life

and prevent damage and deterioration to this instrument. To avoid potential hazards, use

this product as specified.

■Warnings on the Cases and Panels of the Instrument

Operator should not remove any cases or panel for any reasons. If you touch

inside the instrument it could result personal shock or fire hazard. Refrain

from spilling any liquid on or inserting anything flammables or piece of metal

into the ventilation of the instrument. Such actions could cause fire, shock,

malfunction and be an accident hazard while the power is on.

■Warnings on Power Line

●Make sure to connect only to the rated power line voltage. Excess

voltage may cause fire.

Confirm the voltage of the commercial power line before connecting the AC power

cord. The power frequency of the power line should be 50/60 Hz.

●Warning on the Power Cord

Use only the optional power cord that is attached to this instrument. The use of the

power cord other than that attached could cause fire hazard.

If the attached cord is damaged stop using it and contact your local LEADER

agent. Should you use a damaged cord, it could cause a shock or create a fire

hazard. When you pull out the cord be sure to hold it by plug and pull from the

socket not by holding the cord wire.

■Warning on Fuse

When the fuse is melted the instrument stops operation. If the fuse melted, turn off the

power switch and disconnect the power plug from the socket. If you change the fuse

while the cord is connected to the socket, it could cause a shock hazard. Only use the

specified type and rated current and voltage fuses.

If the cause for melting fuse is unclear or if you suspect there is damage to the instru-

ment or if you have no proper fuse at hand please contact your local LEADER

agent.

— III —

WARNING

GENERAL SAFETY SUMMARY

■Warning on Installation Environments

●About the Operating Temperature Range

Operate the instrument between the temperature range of 0 to 40 °C. Operating the

instrument at higher temperatures could cause a fire hazard.

Rapid changes of temperatures from cold to warm can create internal moisture or

condensation and could damage the instrument. If there is a possibility of moisture

condensation allow the instrument to sit for 30 minutes without the power on.

●About the Operating Humidity Range

Operating humidity range is ≤90 % RH.

Do not operate the instrument with wet hands. This could cause a shock and fire

hazard.

●About the Operation in the Presence of Gasses

Operating the instrument in and near the presence or storage locations of flam-

mable, explosive gasses or fumes could create an explosion and fire hazard. Do not

operate the instrument anywhere near such environments.

●Avoid Insertions

Do not insert metals or flammable objects or drop liquid on or into the instrument.

To do so could cause fire, shock, malfunction and create a dangerous accident haz-

ard.

■Warning while Operating

While operating the instrument if smoke, fire, or a bad smell occurs, turn off the instru-

ment at once for it could cause a fire hazard. When such a case occurs, turn off the

power switch and pull the plug of the cord from the plug socket. Contact your local

LEADER agent after confirming there is no fire.

■Warning about Ground

The instrument has a ground terminal to avoid electric shock hazard and to protect the

instrument from damage. Ensure that the product is properly grounded for safe opera-

tion.

— IV —

CAUTION

■Caution when Not to Use the Instrument for a Long Time

Make sure to disconnect the power cord from the socket when you do not use the

instrument for a long time.

GENERAL SAFETY SUMMARY

■Caution on Input/Output Terminals

Input Terminals are rated with a maximum input. Do not supply an input over the

specified rating in the standard section of the instruction manual. Also, do not supply

external power to Output terminal, this could cause the instrument to malfunction.

Please conform to the above warnings and cautions for safe operation. There are cautions

in each area of this instruction manual, so please conform to each caution. If you have any

questions about this manual, please feel free to contact your local LEADER agent.

1. INTRODUCTION

Thank you for purchasing Leader’s measuring instruments.

Please read this instruction manual carefully to ensure correct and safe operation.

If you have any difficulties or questions on how to use the instrument after you have read this

manual, please feel free to contact your local LEADER agent.

1.1 Scope of Warranty

This LEADER instrument has been manufactured under the strictest quality control

guidelines.

LEADER shall not be obligated to furnish free service during the warranty period under the

following conditions.

1. Repair of malfunction or damages resulting from fire, natural calamity, or improper

voltage applied by the user.

2. Repair of an instrument that has been improperly repaired, adjusted, or modified by

personnel other than a factory-trained LEADER representative.

3. Repair of malfunctions or damages resulting from improper use.

4. Repair of malfunctions caused by devices other than this instrument.

5. Repair of malfunctions or damages without the presentation of a proof of purchase or

receipt bill for the instrument.

1-1

CAUTION

1.2 Operating Precautions

WARNING

1.2.1 Line Voltage and Fuse

Confirm that the power line voltage is correct before connecting the power cord.

The voltage range and fuse rating are indicated on the rear panel.

When replacing the fuse, turn the power switch off and disconnect the power cord

from the mains.

Voltage Range Fuse

Rating LEADER Parts Number

90 to 250 V T0.63AL, time-lag 436 3555 005

1.2.2 Reverse Voltage

•Shorting the output connectors

Do not short any output connectors to prevent damage to the instrument.

•Do not apply external voltage to the output connectors. It can cause trouble.

1.2.3 Installation

Do not use the instrument in the following environments.

•High temperature environments

Do not place the instrument under direct sunlight or near a heater (e.g., stove).

Do not move the instrument from cold to warm environment abruptly, it may cause

condensation.

Operating temperature range: 0 to 40 °C

•High humidity environments

Do not place the instrument in the high humidity environment (e.g., bathroom, near

a humidor).

Operating humidity range: ≤90 % RH

•Dusty environments

1-2

1.2.4 Mechanical Shock

Please be careful not to expose the instrument to other forms of severe mechanical

shock as this product contains shock sensitive precise parts.

1.2.5 Calibration

When calibration or service is required, contact your local LEADER agent.

1.2.6 Routine Maintenance

When cleaning the instrument, do not use such solvents as thinner or benzol which

will remove paint or damage the plastic surface. Use a soft cloth dampened with

neutral detergent.

Do not drop water or detergent, or insert metal object into the instrument while

cleaning. Otherwise, you run the risk of electrical shock or fire.

1-3

2. SPECIFICATIONS

2.1 GENERAL

Model LT 416 is a precision test-signal source which provides four color systems of

NTSC, PAL, SECAM, and NTSC-4.43 for testing and adjusting all kind of video

products such as TV, VTR etc.

In addition of a composite signal output, the generator provides a Y/C output and a

component signal outputs (except SECAM) of Y/B-Y/R-Y and GBR so that it is

suitable to a production line for video products of component system.

RF output is easily selected by setting channel number while the channels are pre-

programmed by each countries.

15 test patterns including color bars, raster, convergence and circle satisfy the most

desired applications.

2.2 FEATURES

•Conforms to four standards (i.e., NTSC, PAL, SACAM, NTSC-4.43)

This generator is ideal for adjusting and testing TVs, VTRs, and AV equipments.

•Sconnector

An S connector is provided to output Y and C signals for adjusting AV equipments

with S connector.

•Component video signal output

This generator outputs the composite video signal and component video signal.

Since Y/ B-Y/ R-Y or G/ B/ R is output, the generator allows test signals for

component AV system adjustment and testing. (The SECAM color signals

(B-Y, R-Y) are not output.)

•RF setting

The channel plan based on the country system is provided for easier RF frequency

setting.

•Various test patterns

The 15 patterns including color bar and circle are provided for various adjustment

and test processes.

2-1

2.3 Specifications

2.3.1 Composite Video Signal Output

(1) Color System: NTSC, PAL, SECAM, NTSC-4.43

(2) Scanning Method

NTSC/ NTSC-4.43: 525-line interlace scanning

PAL/ SECAM: 625-line interlace scanning

(Progressive scanning can be performed for all color systems when the

CIRCLE or CONVERGENCE pattern is selected.)

(3) Field frequency

NTSC: 59.94 Hz ±30 ppm

(60.06 Hz ±30 ppm for progressive

scanning)

PAL/ SECAM: 50 Hz ±30 ppm

(50.08 Hz ±30 ppm for progressive

scanning)

NTSC-4.43: 59.94 Hz ±150 ppm

(60.06 Hz ±150 ppm for progressive

scanning)

(4) Line frequency

NTSC: 15.734 kHz ±30 ppm

PAL/ SECAM: 15.625 kHz ±30 ppm

NTSC-4.43: 15.734 kHz ±150 ppm

(5) Subcarrier Frequency

NTSC: 3.579545 MHz ±30 ppm

PAL: 4.43361875 MHz ±30 ppm

NTSC-4.43: 4.43361875 MHz ±50 ppm

(Progressive scanning can be selected when

CIRCLE or CONVERGENCE patterns is

selected.)

(6) Video Generating System: Digital system using 4 fsc sampling (without

SECAM)

(7) Number of Quantitative Bits: 8 bits

(8) Output Impedance: 75Ω

(9) Output Level: 1 Vp-p ±50 mVp-p (Between sync tip and

100 % white)

0 to 1 Vp-p, continuous variable

2-2

(10) Setup Level: NTSC: 0 % (“7.5 %” model optionally

available)

PAL/SECAM/NTSC 4.43 : 0 %

(11) Output connector

Variable output: BNC

Fixed output: RCA jack ............. 1

(12) Number of Outputs: 1 each ................. 1

2.3.2 Sync Signal

(1) Sync Signal

Amplitude

NTSC/ NTSC-4.43: 286 mVp-p ±14 mVp-p

PAL/ SECAM: 300 mVp-p ±15 mVp-p

Horizontal Sync Width: 4.7 µs ±200 ns (same spec.)

Vertical Sync Width

NTSC/ NTSC-4.43: 3H

PAL/ SECAM: 2.5H

Vertical Blanking Period

NTSC/ NTSC-4.43: 20H

PAL/ SECAM: 25H

(2) Color Burst

Amplitude

NTSC/ NTSC-4.43: 286 mVp-p ±23 mVp-p

PAL: 300 mVp-p ±24 mVp-p

Number of Cycles

NTSC: 9 cycles

PAL: 10 cycles

NTSC-4.43: 11 cycles

(3) SECAM Color Identification Signal

Amplitude

D’R Line: 540 mVp-p +40 mVp-p, -50 mVp-p

D’B Line: 500 mVp-p ±50 mVp-p

(4) SECAM Color (Back porch on the horizontal blanking period)

Amplitude

D’R Line: 215 mVp-p ±25 mVp-p

D’B Line: 167 mVp-p ±20 mVp-p

2-3

2.3.3 Test Patterns

(1) Color Bar: 100/ 0/ 75/ 0 Full-field Color Bar

(2) Demodulator Pattern (Not output when the SECAM is selected)

PAL: Combination of normal and reversed B-Y

and R-Y for each line

NTSC: Combination of normal and reversed B-Y,

R-Y, I, and Q for each line

line n: R-Y, -(R-Y), B-Y, -(B-Y), R-Y, -(R-Y), B-Y,

-(B-Y)

line n+1: -(R-Y), R-Y, B-Y, -(B-Y), R-Y, -(R-Y),-(B-Y),

B-Y

line n: I, -I, Q, -Q, I, -I, Q, -Q

line n+1: -I, I, Q, -Q, I, -I, -Q, Q

(3) Multiburst

Frequency

NTSC/ NTSC-4.43: 0.5, 1.0, 2.0, 3.0, 3.58, 4.2 MHz

PAL/ SECAM: 0.5, 1.0, 2.0, 4.0, 4.8, 5.5 MHz

Amplitude: 100 %(*)

(4) Raster

Output eight colors in combination with red, green and, blue

Color: 100 % white, yellow, cyan, green, magenta, red, blue, black

Amplitude: Same as color bars

(5) Window

Window Amplitude: 100 %(*)

(6) Step

10 equal steps from 0 mV to 700 mV white

(7) Circle Pattern: White circle pattern (with black fringe) on the

convergence pattern

Color Burst: on/off selectable

Interlace/ Progressive: Selectable

(Flicker may occur on the border of convergence and circle patterns.)

(8) Convergence

Luminance Amplitude: 75 %(*)

Number of Vertical Lines

NTSC/ NTSC-4.43: 17

PAL/ SECAM: 19

2-4

Number of Horizontal Lines

NTSC/ NTSC-4.43: 14

PAL/ SECAM: 15

Horizontal Line Width: 2 lines

Number of Dots

NTSC/ NTSC-4.43: 16 x 13

PAL/ SECAM: 18 x 14

Dot Pulse Vertical Width: 2 lines

Color Burst: On/ off selectable

Interlace/ Progressive: Selectable

(*) Notes on pattern specifications

Signal amplitude (100 %) is as follows.

PAL/ SECAM: 700 mVp-p

NTSC/ NTSC-4.43: 714 mVp-p

Accuracy: Same as the composite signal

2.3.4 Y/ C Separation Output

Specifications: Same as the composite signal

Output Impedance: 75 Ω

Connector: S type

Number of Outputs: 1

2.3.5 Y, B-Y, R-Y Output

Output Signal (*2): Y, B-Y, R-Y

Y Output Amplitude

NTSC/ NTSC-4.43: 714 mVp-p ±36 mV

PAL: 700 mVp-p ±35 mV

Sync Signal Amplitude

NTSC/ NTSC-4.43: 286 mVp-p ±14 mV

PAL: 300 mVp-p ±15 mV

B-Y, R-Y Output Amplitude: 525 mVp-p ±26 mV

Output Impedance: 75 Ω

Connector: BNC

Number of Outputs: 1 each

(*2) B-Y and R-Y are output when the SECAM is selected;

Y is only output.

2-5

2.3.6 R, G, B Output

Output Signal (*3): R, G, B, C.SYNC

R, G, B Output Amplitude: 700 mVp-p ±35 mV (NTSC, PAL,

NTSC-4.43)

C.SYNC Output Amplitude: C-MOS Level (NTSC, PAL, SECAM,

NTSC-4.43)

Output Impedance: 75 Ω

Connector: BNC

Number of Outputs: 1 each

(Pulse noise may be superimposed n the leading and trailing edges of the R, G

and B Sync signals.)

(*3) R, G, B are output when the SECAM is selected;

C.SYNC is only output.

2.3.7 RF Output

System

NTSC: M

PAL: B, D, G, H, I, K

SECAM: B, D, G, H, K, L

(The RF is disabled when the NTSC-4.43 is selected)

Carrier Frequency Range: VHF and UHF

Carrier Frequency Setting Method: Direct setting using programmed country

channel plan (Arbitrary frequency cannot be

set)

Modulation Polarity: Negative or Positive

Modulation System: Double sideband

Sound Signal

Intercarrier Frequency: 4.5, 5.5, 6.0, 6.5 MHz

Modulation Signal: 1 kHz ±200 Hz

Modulation System: FM or AM

Output Voltage

VHF: At least 1 mVrms (into 75 Ω)

UHF: At least 0.5 mVrms (into 75 Ω)

Number of Output: 1 (75 Ω, BNC)

Since a double sideband modulation system is used for the RF signal of the LT 416.

such parameters as P/S ratio do not conform to the official standards.

Therefore, video noise or audio noise may appear on a TV monitor, etc. when the RF

signal of the LT 416 is applied.

2-6

2.3.8 Sound Output

Output Signal: 1 kHz ±100 Hz, sine wave

Amplitude: 1.2 Vp-p (into 600 Ω)

Output Impedance: 600 Ω

Number of Output: 1 (RCA jack)

2.3.9 General Specifications

Environmental Conditions

Operating Temperature: 0 to 40 °C

Operating Humidity: ≤90 % RH (without condensation)

Spec-Guaranteed Temperature: 10 to 30 °C

Spec-Guaranteed Humidity: ≤85 % RH (without condensation)

Operating Environment: Indoor use

Operating Altitude: Up to 2000 m

Overvoltage Category: ΙΙ

Pollution Degree: 2

Power Requirements: 90 to 250 VAC, 50/ 60 Hz Max.15 W

Dimensions: 426 (W) x 88 (H) x 300 (D) mm

(excluding projections)

Weight: 4.6 kg

Accessories: Power cord .............................. 1

Instruction manual ................... 1

2-7

3. PANEL DESCRIPTION

Please refer to each item number described on Figure 3-1 and 3-2 for the described

instruction after 4.OPERATING PROCEDURE.

3.1 Front Panel

Figure 3-1 Front Panel

qPOWER switch

Push this switch in to apply power. Release this switch for turning power off.

wPattern keys

Select the pattern.

eR, G, B keys

Set raster color when the raster pattern is selected. Eight colors can be set in

combination with the keys pressed.

rPROGRESSIVE/ INTERLACE key

Select the scanning system when “CIRCLE” or “CONVERGENCE” is selected

by using the “Pattern Keys w.”

When the PROGRESSIVE is selected, the key LED light. When the INTERLACE

is selected, the key LED goes off.

tBURST key

Selects the color burst on or off when “CIRCLE” or “CONVERGENCE” is

selected by using the “Pattern Keys w.” When the signal with color burst is

output, the key LED lights; when the signal without color burst is output, the key

3-1

qwuio!3 !4 !6 !7

ert y!0 !1 !2 !5 !8

LED goes off.

In the SECAM system, this key is used to turn on or off the reference burst.

y COUNTRY/ CHANNEL u CHANNEL/ COUNTRY display i SELECT keys

This block is used to control the RF frequency.

Press the COUNTRY/ CHANNEL ywhen selecting the TV channel number and

country number.

When the COUNTRY LED light, the country number being selected is displayed

on the CANNEL/ COUNTRY display u.

When the CHANNEL LED light, the TV channel being selected is displayed on

the CHANNEL/ COUNTRY display u.

Use the SELECT ito select the country number and channel number.

The COUNTRY/ CHANNEL yis also used to turn on or off the sound subcarrier

on the RF output.

oSYSTEM

Selects the color system.

!0 AUDIO OUTPUT connector

Outputs 1 kHz sine wave in fixed level.

RCA jack is used. Output impedance is 600 Ω.

!1 VIDEO OUTPUT connector

Outputs composite video signal in fixed level.

RCA jack is used. Output impedance is 75 Ω.

!2 Y/C OUTPUT connector

Outputs Y and C video signals in fixed level.

S connector is used. Output impedance for both Y and C is 75 Ω.

!3 VIDEO OUTPUT !4 LEVEL !5 OUTPUT

This group is used to control the composite video signal output level.

OUTPUT connector is BNC, and output impedance is 75 Ω.

The level is calibrated at the PRESET (detent) position.

The output level can be set from 0 V (MIN, immediately before the detent

position) to the preset level (MAX) by rotating the OUTPUT LEVEL control.

!6 RF OUTPUT !7 LEVEL !8 OUTPUT

This group is used to control the RF output level.

OUTPUT connector is BNC, and output impedance is 75 Ω.

OUTPUT LEVEL control sets the output level. Clockwise rotation increases

output level.

3-2

3.2 Rear Panel

This section describes the rear panel according to Figure 3-2.

Figure 3-2 Rear Panel

!9 Y, B-Y, R-Y connectors

Output component video signal with fixed level. Luminance signal (Y) and color

difference signal (B-Y, R-Y) are output.

Output impedance of each connector is 75 Ω.

@0 R, G, B, C.SYNC connectors

Output RGB video signal and composite sync signal with fixed level. Output

impedance of R, G, and B connectors are 75 Ω. The C.SYNC is output in C-MOS

level.

@1 Inlet

Connect the accessory power cord.

Usable AC voltage range is 90 to 250 V, universal.

@2 Fuse holder

The fuse rating is indicated on the rear panel. When replacing the fuse, rotate the

fuse holder cap counterclockwise using a Phillips screwdriver to remove the cap.

@3 Ground terminal

This terminal is connected to the chassis, and is used for grounding.

@4 Serial number plate

Instrument serial number. Provide this number when contacting us.

3-3

@0 @1 @2

@4 @3

!9

Table of contents

Other Leader Electronics Corp. Portable Generator manuals

Popular Portable Generator manuals by other brands

Furius

Furius FORCE 800 user manual

Generac Power Systems

Generac Power Systems 9801-7 owner's manual

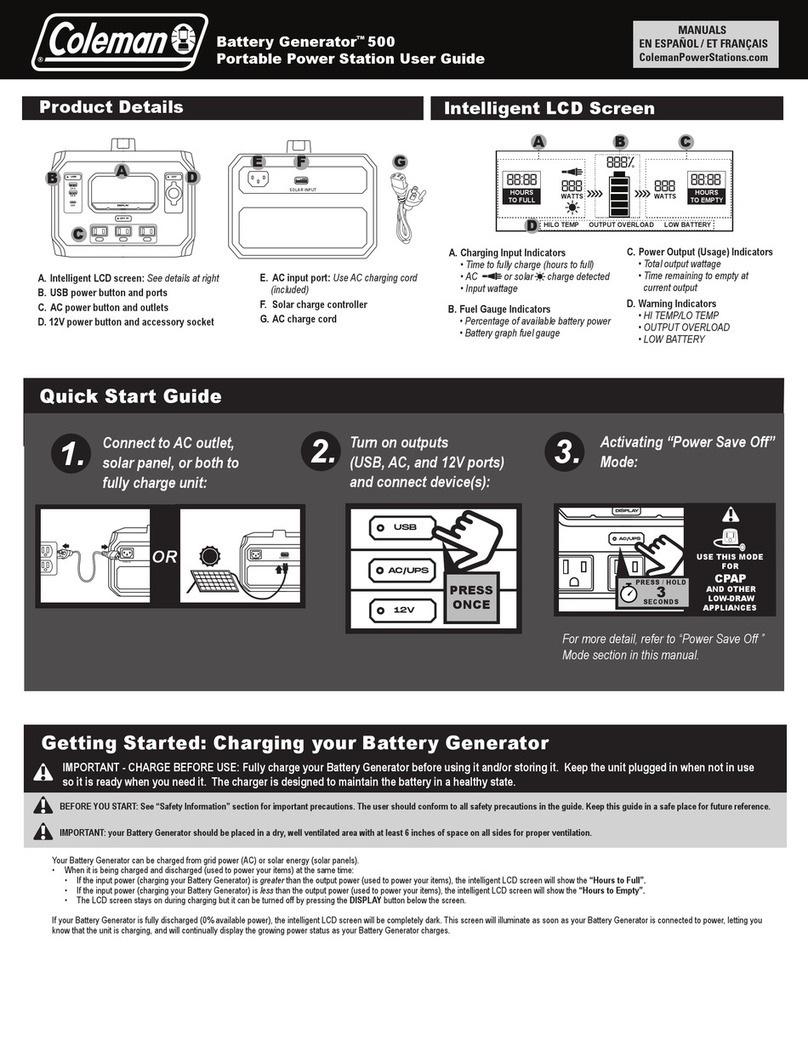

Coleman

Coleman Battery Generator 500 user guide

Generac Power Systems

Generac Power Systems 17,500 WATT Warranty information booklet

Yamaha

Yamaha EF2400iSHC owner's manual

EcoFlow

EcoFlow Smart Generator Dual Fuel user manual