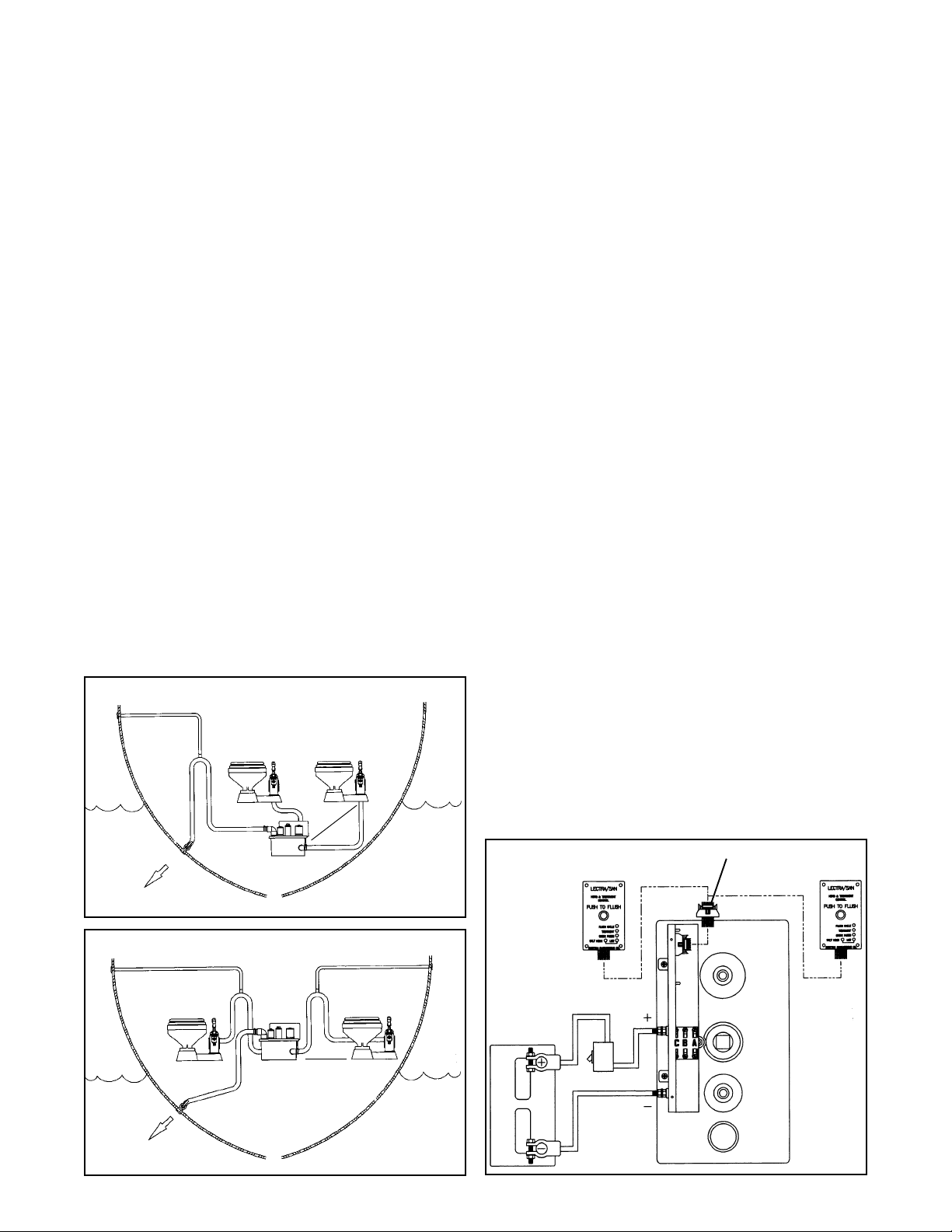

2

FLUSH CYCLE ➀

TREATMENT ➁

CHECK FUSES ➂

SALT HIGH ➃ LOW ➃

LECTRA/SAN

HEAD & TREATMENT

CONTROL

PUSH TO FLUSH

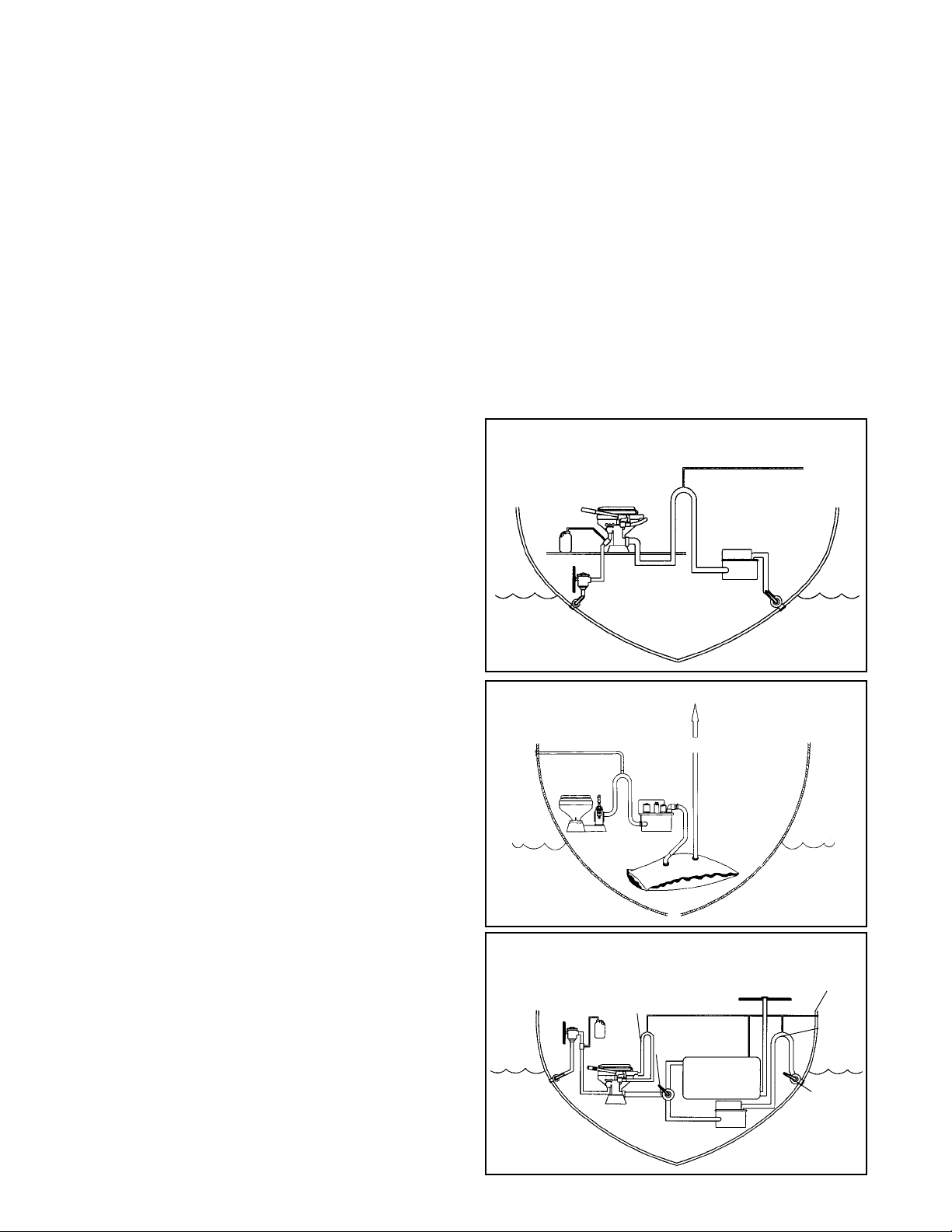

Fig. #1

Light Sequence:

➀Flush toilet only while

green flush cycle light is

on (first 40 sec.).

➁Treatment light (green)

will remain on for entire

cycle.

➂Check Fuse light (red) on:

See Troubleshooting.

➃High Salt or Low Salt

light (amber) on: Treat-

ment will continue. See

Troubleshooting.

2. If using a manual toilet or electric toilet installed

on a separate circuit, Lectra/San EC must be

activated before flushing the toilet.

TREATMENT CYCLE

(How it Works and What it Does)

The flushing action of the marine toilet discharges

waste and water into the first chamber of the Treat-

ment Unit. There, waste is macerated and treated.

Proprietary electrode plates are electrically ener-

gized to temporarily convert salt water into a strong

bactericide, hypochlorous acid. This solution treats

thewasteby eliminatingbacteria and viruses,then it

reverts back to the original state of salt and water.

Upon the next flush of the toilet, additional waste

enters the first chamber, forcing some of its treated

contents into the second chamber. While the new

waste is being macerated and treated in the first

chamber, the contents of the second chamber are

stirred and given additional treatment. A mixer is

locatedinthesecondchambertopreventsludgefrom

accumulating and to ensure uniform treatment of its

contents.

Successiveflushesmovetheoriginaltoiletdischarge

through the Lectra/San EC and eventually over-

board. When the discharge enters the water it is

completely treated and no harmful elements are

added to the environment.

MAINTENANCE

IMPORTANT: Cleaning and Winterization

instructionsarebasedonhaving an electric toilet

connected to the Lectra/San EC for single button

operation.

Periodically inspect the unit for leaks and check for

loose plumbing and electrical connections.

WARNING: If the toilet is wired on its own

circuit,ormanuallyoperated, make sure power

toLectra/SanECisOFF priortocleaningand/or

winterizing.

CLEANING

WARNING: DO NOT activate the Lectra/San

EC during this procedure. Discharge seacocks

must be in OPEN position.

NOTE: The following procedures pertain to use

with single button operation toilets.

Completely read all instructions before begin-

ning the procedure.

Treatment Tank:

1. RemovethethreefusesfromtheControlModule

(locatedonthetopoftheTreatmentTank). Mark

each fuse for replacement purposes. Fuse re-

moval will permit operation of an electric toilet

without activating the Lectra/San EC.

2. Shutoff intakeseacocktothetoilet,ifnecessary.

Once fuses have been disconnected, flush bowl

as dry as possible.

WARNING: Beforeusingacid,observesafehan-

dling instructions on container.

3. Add one pint of muriatic acid, 31% by weight

(availablefromhardwarestores), toatwogallon

plastic bucket of fresh water.

4. Pour the solution into the toilet and flush the

toilet (press button) as dry as possible so the

solution is forced into the treatment unit.

5. Pour an additional gallon of fresh water into the

toiletbowltodilutetheremainingacid. Letstand

for 45 minutes before flushing toilet.

6. Open intake seacock or water supply. Flush the

toilet as often as possible during the flush cycle.

(DuringtheTreatment Cyclethe toiletcannot be

flushed.) Allow the Treatment Cycle to finish.

Repeat four times.

6a. For toilets which are not controlled by the

Lectra/Sancontrolopenintakeseacockand water

supply. Flush the toilet at least 15 times for 15

seconds each time (minimum of 10 gallons rinse

water) to effectively dilute and discharge the

Lectra/San EC contents.

DO NOT FLUSH TOILET AFTER THE

FLUSH CYCLE LIGHT GOES OFF.