8

301 Thor Place, Brea, CA 92821 | tel (714) 256-2111 | fax (714) 256-2118 | sales@ledconn.com | www.ledconn.com

Details are subject to change without notice. © 2019 LEDCONN CORP. All Rights Reserved.

IG.20.01.R0

INSTALLATION GUIDE

SCAN FOR

DIGITAL VERSION

IMPORTANT SAFETY INSTRUCTIONS

Installation of this assembly requires a person familiar with the construction and operation of the luminaire's electrical system and the

hazards involved. If not qualified, do not attempt installation. Contact a qualified electrician If you are unfamiliar with methods for

installing electrical wiring, secure the services of a qualified electrician.

LEDCONN LED fixtures are designed to meet the latest NEC requirements and are listed in full compliance with the relevant UL

standard(s). Before attempting installation of any LED fixture, check your local electrical building code. All electrical connections must

be in accordance with local codes, ordinances and the National Electric Code. Always confirm that the maximum wattage of the flexible

sheet does not exceed the maximum wattage of the connected electrical circuit.

• IMPORTANT Risk of fire or electric shock. Installation of this

luminaire assembly requires a person familiar with the construction

and operation of the luminaires electrical system

and the hazard involved. If not qualified, do not attempt installation.

Contact a qualified electrician

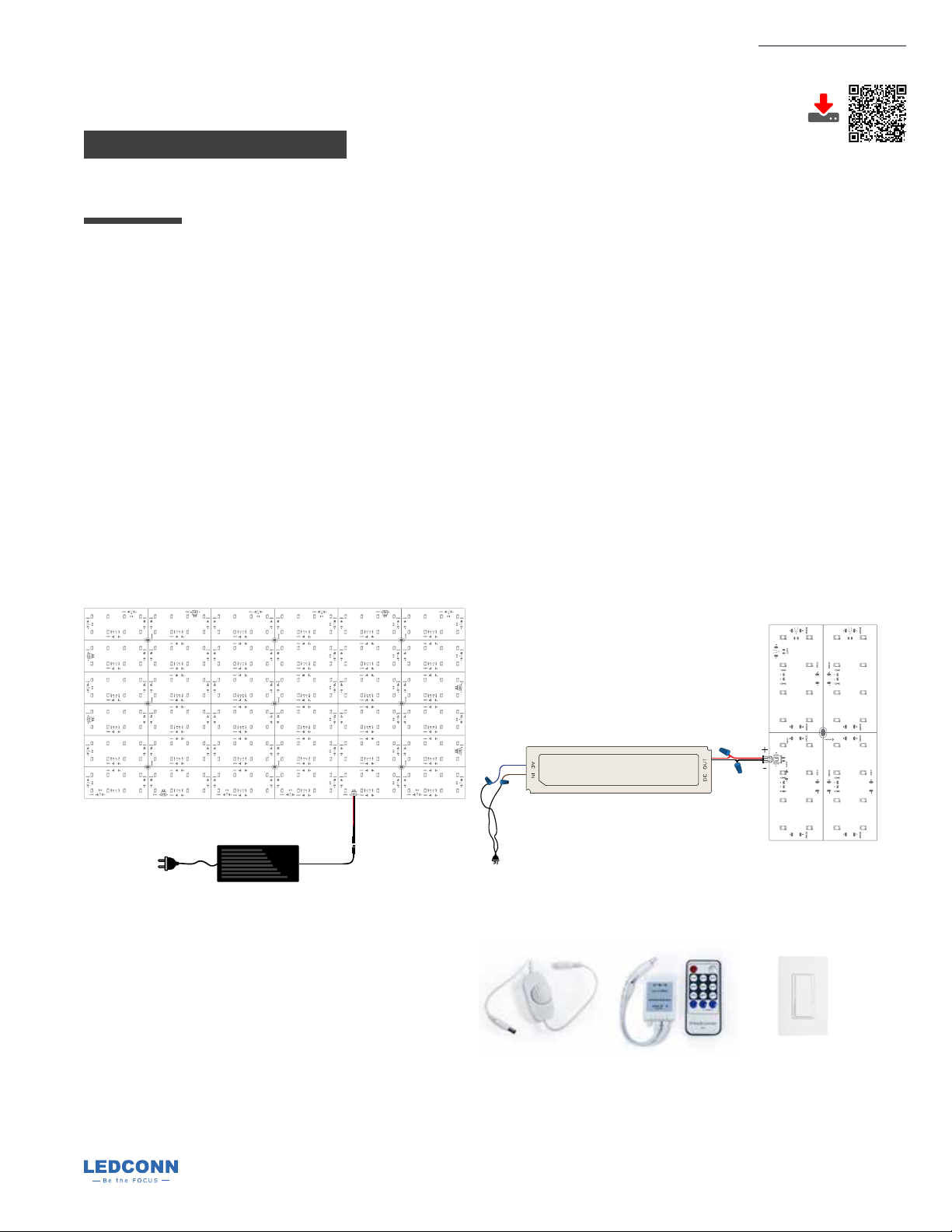

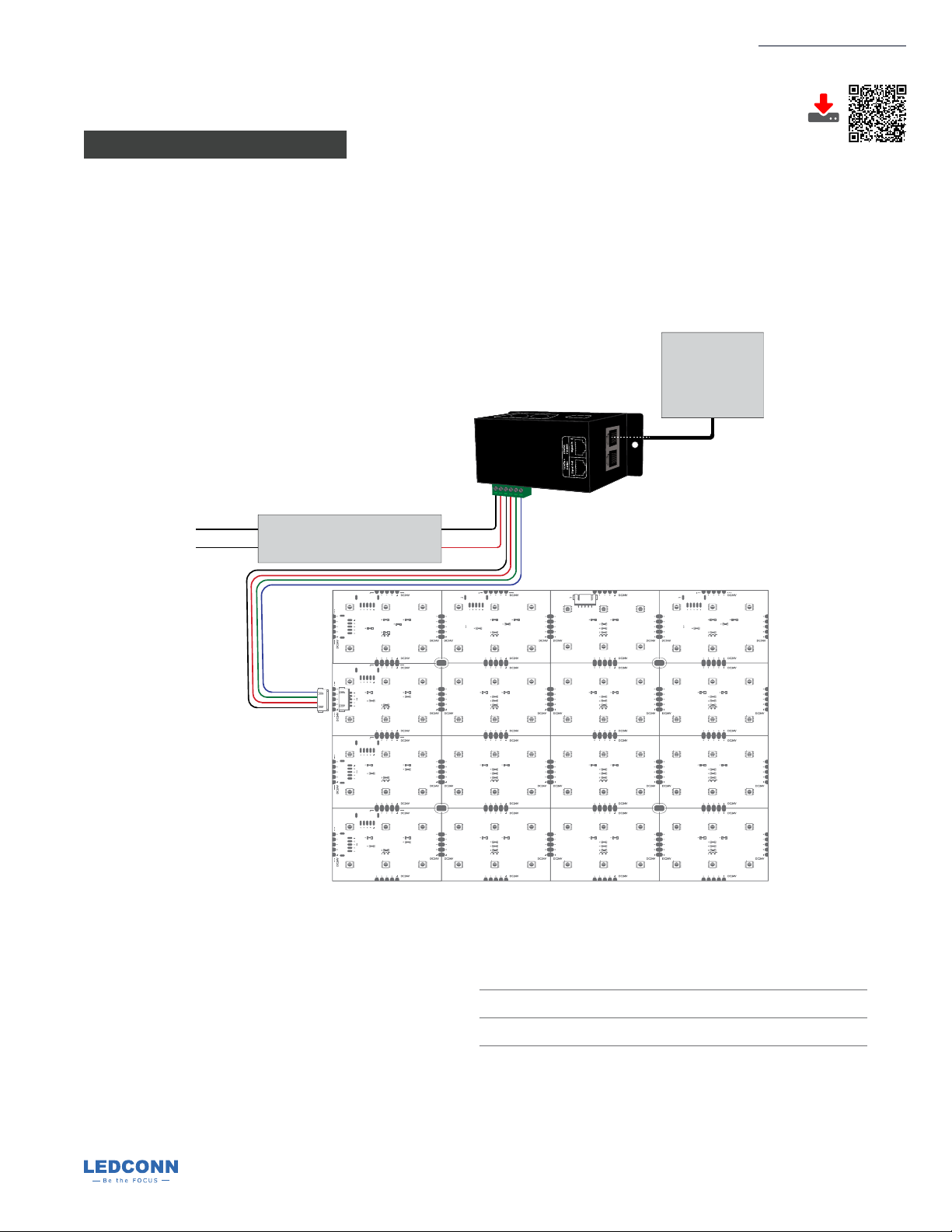

• IMPORTANT Do not connect directly to AC power!

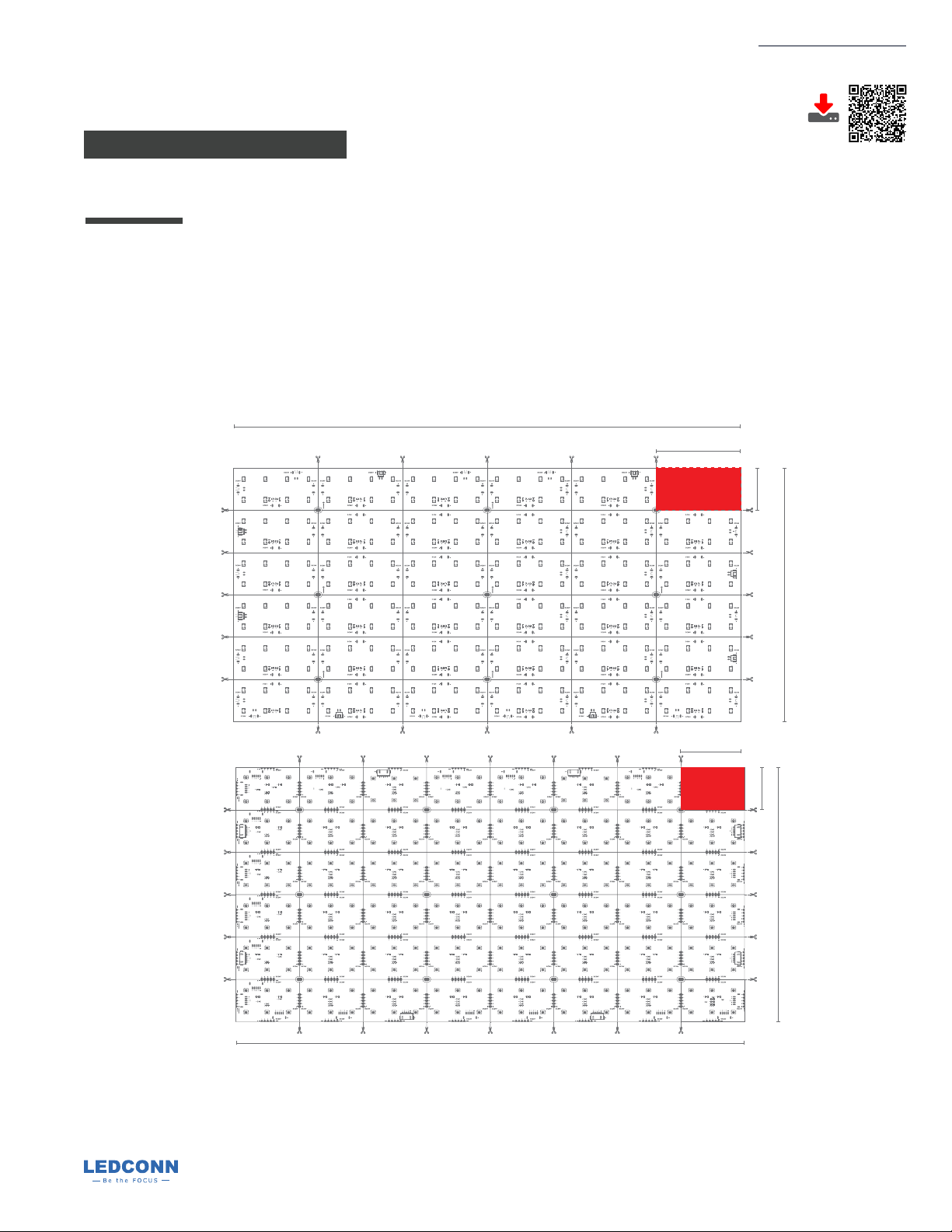

• IMPORTANT Risk of fire or electric shock. Install this assembly only

if the luminaires have the construction features and dimensions shown

in the photographs and/or drawings

•IMPORTANT To prevent wiring damage or abrasion, do not pinch or

damage expose wiring during installation. Keep away from to edges of

sheet metal or other sharp objects

• Verify power is off before installing or un-installing.

• Do not use product if any LED flexible sheet components are

damaged.

• The product has no user serviceable parts. Do not attempt to open

the product or repair it on site. If damaged, please notify LEDCONN

immediately for servicing.

• Do not exceed the specified voltage and current input (refer to the

specification sheet for power limitations).

• Do not hot plug the light engine to an energized power supply, hot

plugging may cause permanent damage to the LEDs.

• Avoid looking directly into the luminaire as the high brightness beam

may damage eyes.

• LEDCONN’s limited warranty applies only to LEDCONN's LUXFLEX

Standard, LUXFLEX Premium, and LUXFLEX RGBW.

• This product must be installed in accordance with the applicable

installation code by a person familiar with the construction and

operation of the product and the hazards involved.

• Do not make or alter any open holes in an enclosure of wiring or

electrical components during installation.

• Please retain these instructions for maintenance reference.

• Test before installing; LEDCONN products undergo rigorous

reliability testing before shipment, but due to unforeseen shipping and

handling issues inspect all flexible sheets to confirm receipt of good,

functioning luminaires.

WARRANTY

These handling and mounting materials and any other communications related to the installation of LUXFLEX LED flexible sheets are offered

for informational purposes only. Handling and mounting is the installer's responsibility. Under no circumstances is LEDCONN assuming any

liability, express or implied, regarding the installation or application of any of its LUXFLEX LED flexible sheets, whether proper or improper.

Further, LEDCONN assumes no liability for any costs associated with the installation or re-installation of LUXFLEX LED flexible sheets.

The standard warranty for this product is 5 years. Any damage caused by mishandling or improper installation of the product as outlined in

this installation guide will void the warranty. Examples of mishandling or improper use include but are not limited to: not cutting along product

cut lines; using power supplies or controls not recommended by LEDCONN; and using product in damp environments without proper damp

location treatment and installation. Please consult a LEDCONN team member for more information about the warranty coverage.

LIMITED

MANUFACTURER

WARRANTY

• LUXFLEX Standard and RGBW are provided by default with an IP54

rating that provides only partial protection against dust and water

splashing from all angles. Please avoid getting the product wet.

• Damp location rating (IP65) is provided for LUXFLEX Premium by

default with IP65. If your LUXFLEX Standard or RGBW product has

been custom requested with IP65 treatment, then it may also be

considered as a damp location product.

• Environmental factors will affect the type of IP rating required for

your applicaiton. If a custom IP Rating has been requested, please

consult with our engineering team for more specific information.

• Relative humidity should never exceed 70% MAX for indoor

applications.

STORAGE & MAINTENANCE

• For optimal LED performance, make sure LUXFLEX™ LED Flexible

Sheets do not exceed an operating temperature range of -4˚F min to

+140˚F max (-20˚C min to +60˚C max).

• For product without damp location treatment, store in a dry, clean

area.

• LUXFLEX may be cleaned, with the power off, by gently wiping with

a soft cloth, using care not to snag or harm the LED components.

• If LUXFLEX is dusty, turn the power off and apply compressed air to

clear any debris.

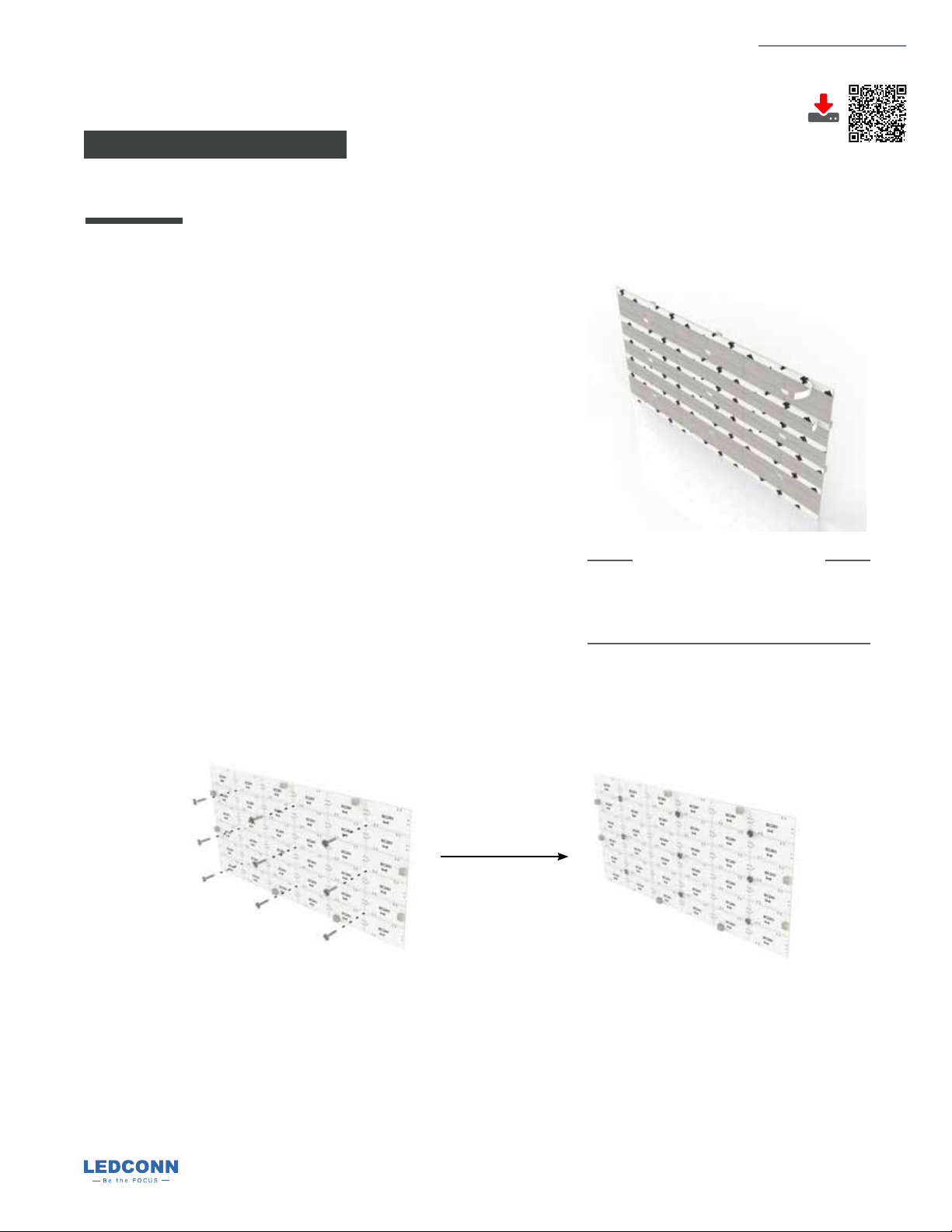

LUXFLEX™

Static White & RGBW

FLEXIBLE SHEET