9

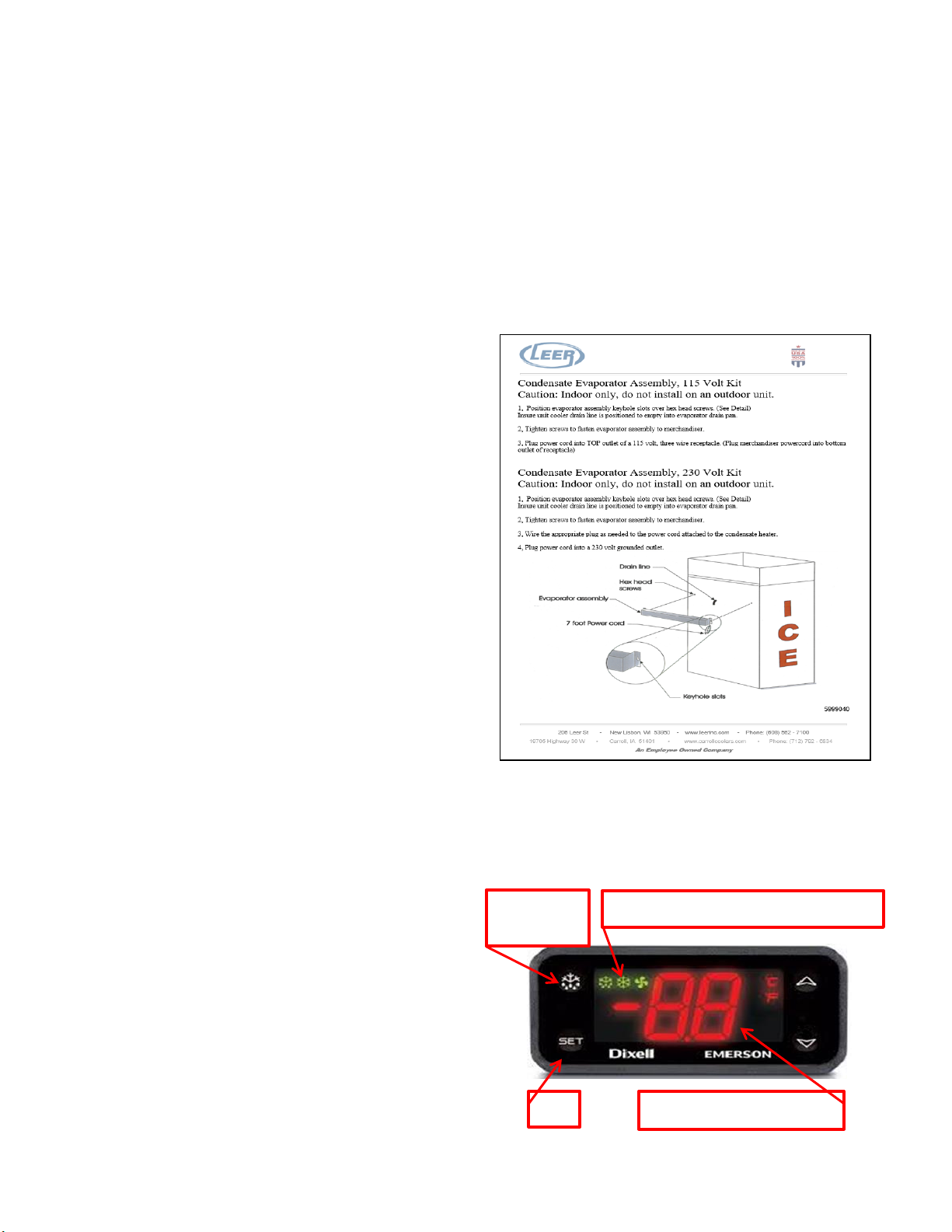

The electronic defrost circuit is equipped with a

defrost termination safety switch and is attached

to one of the evaporator coil tubes (located inside

the Unit Cooler Assembly). This switch senses

temperature and will cut power to the defrost heat

element should the temperature at the surface of

the switch reach 100° F. This switch only

terminates power to the heat element and will not

end the timed / temperature defrost cycle. Once

the merchandiser has returned to run mode, the

termination safety switch will re-set when the

temperature at its’ surface reaches 70° F.

Warning! The defrost termination safety switch

functions as a possible fire protection device. Do

not remove or by-pass the switch from the defrost

circuit.

Note: If an electronic control AD unit loses power

and the temperature at “P2” is less than 60°F, it

will automatically enter a defrost cycle after a

two-minute delay.

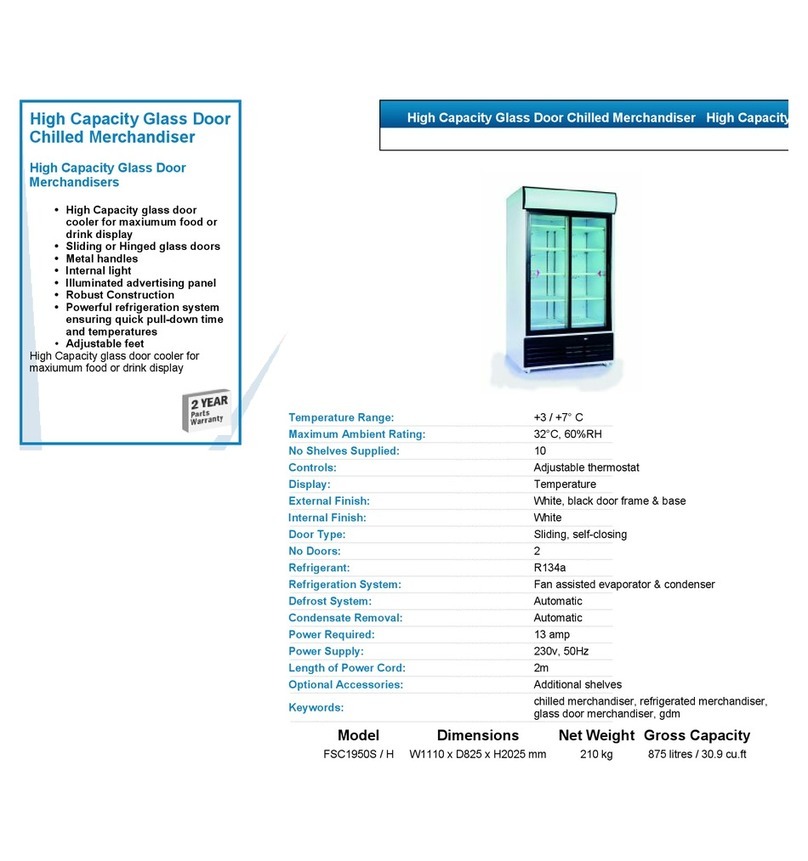

Glass Door Models and Maintenance:

The glass door is designed for use on indoor units

or in a controlled environment. It is constructed

with a non-heated, triple-pane glass-pack, with

both inner and outer panes being tempered. To

avoid possible condensation on the outer surface

of the door, case temperature in the merchandiser

should be maintained near its’ designed set-point

of 16°F +/- 4° and ambient dew-points around the

cabinet location should be kept below 60°F. Any

household glass cleaner can be used to clean the

surface of the door. The glass door’s gasket is a

rubber bellows-style magnetic gasket. The

replacement gasket has an insert dart that installs

into a retaining slot in the door frame. The gasket

can be started in-place with light hand pressure,

followed with mild impact pressure applied with a

dead-blow hammer to ensure that the legs of the

dart penetrate fully into the slot. During

replacement, set the gasket at the 4-corners of the

door first to reduce stretching. If the door gasket

appears to be in good condition but is failing to

seal to the surface of the cabinet, both the spring-

load tension and adjustment of the hinges should

be checked.

Solid Door Models and Maintenance:

Cabinets designed for outdoor use will have a

metal clad door that has been insulated with the

same urethane foam insulation as the cabinet.

The exterior metal is stucco embossed to hide

minor impacts and is coated with a fluorocarbon

paint system. This paint system was designed to

withstand years of outdoor exposure. For routine

cleaning of the door’s exterior surface, a mild

detergent diluted in warm water should be

adequate.

Hinge Spring Tension:

A simple test of the spring-load tension is to open

the door just enough to insert two fingers between

the surface of the cabinet and the handle side of

the door. When the fingers are withdrawn, there

should be enough tension set on the hinge spring-

loads to slowly move the door to a closed

position. If the door does not move from this two-

finger location, it’s likely that either the spring-

load requires re-tensioning or lubrication. If the

door moves part way from the two-finger location

but stops short of the cabinet, the compression of

the gasket along the hinge side of the door should

be checked. If there is too much compression, the

door will bind when closed and should have its

hinge-mount location checked and possibly

adjusted. Removing the hinge covers will expose

the spring-loads for tension adjustment or

removal. Removal of the spring-load will expose

the hinge-adjustment plate and mounting screws

should hinge adjustment be required. See Figure

2for instruction regarding spring-load installation

and adjustment.

Decaling Recommendations Solid Door:

a) Use a decal with a 2-mil cast vinyl

substrate. Cast vinyl contains less

memory than a calendared vinyl or a

polyester substrate and will conform to the

embossed surface with the least amount of

stress on the decal’s adhesive.

b) The decal’s adhesive should have a

minimum peel-strength rating of 80 oz.

/inch.