1

1 Safety information ...................................................................................3

2 Technical data ..........................................................................................5

2.1 Standards and application conditions......................................................................................5

2.2 Ratings...................................................................................................................................6

3 Installation................................................................................................8

3.1 Dimensions and mounting ......................................................................................................8

3.1.1 NEMA 1 (IP31) Models ...................................................................................................8

3.1.3 NEMA 4X (IP65) Models .................................................................................................9

3.2 Electrical installation............................................................................................................. 10

3.2.1 Power Connections......................................................................................................10

3.2.1.1 Mains Connection to 120VAX Single-Phase Supply.......................................10

3.2.1.2 Mains Connection to 240VAC Single-Phase Supply.......................................11

3.2.1.3 Mains Connection to Three-Phase Supply.....................................................11

3.2.1.4 Motor Connection......................................................................................... 11

3.2.1.5 Installation Recommendations for EMC Compliance ..................................... 12

3.2.1.6 NEMA 4X (IP65) Input Terminal Block............................................................ 12

3.2.1.7 Dynamic Brake Connections.........................................................................13

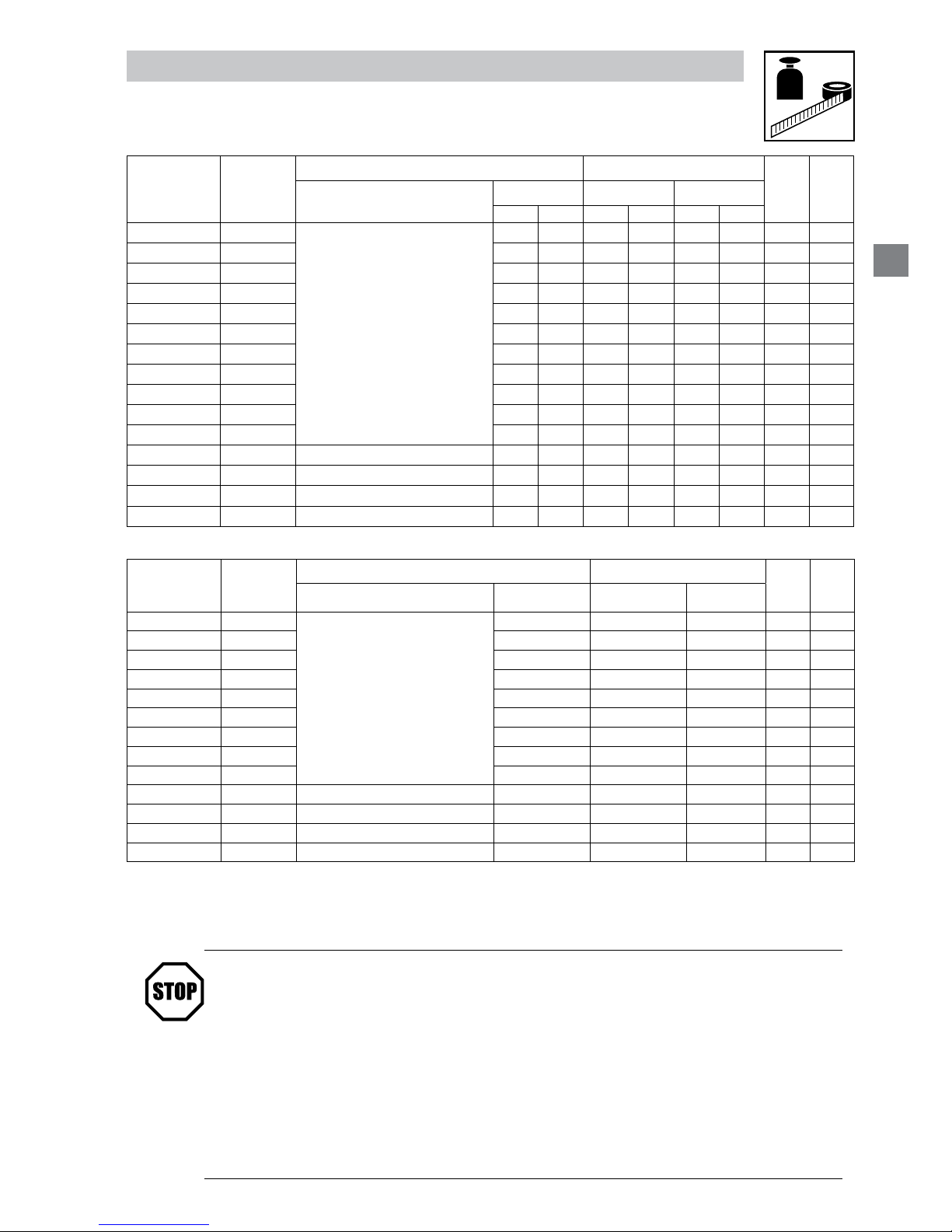

3.2.2 Fuses/cable cross-sections.......................................................................................... 14

3.2.3 Control terminals....................................................................................................... 15

4 Commissioning......................................................................................16

4.1 Local Keypad & Display ........................................................................................................16

4.2 Drive Displays and Modes of Operation................................................................................. 19

4.3 Parameter setting ................................................................................................................. 20

4.4 Electronic programming module (EPM) ................................................................................. 20

4.5 Parameter menu................................................................................................................... 21

4.5.1 Basic Setup Parameters.............................................................................................. 21

4.5.2 I/O Setup Parameters.................................................................................................. 25

4.5.3 Advanced Setup Parameters ....................................................................................... 32

4.5.4 PID Parameters........................................................................................................... 37

4.5.5 Vector Parameters ......................................................................................................40

4.5.6 Network Parameters...................................................................................................43

4.5.7 Diagnostic Parameters................................................................................................44

4.5.7.1 Terminal & Protection Status Display ............................................................46

4.5.7.2 Keypad Status Display..................................................................................46

4.5.8 Onboard Communications Parameters 15-25 HP ........................................................ 47

4.5.9 Sequencer Parameters ............................................................................................... 48

4.5.9.1 Sequencer Flow Diagram Left ...................................................................... 57

4.5.9.2 Sequencer Flow Diagram Right ....................................................................58

4.5.9.3 Sequencer Status......................................................................................... 59

5 Troubleshooting and Diagnostics........................................................60

5.1 Status/Warning Messages .................................................................................................... 60

5.2 Drive Configuration Messages ..............................................................................................62

5.3 Fault Messages ...................................................................................................................... 6

Appendix A ................................................................................................66

A.1 Permissable Cable Lengths...................................................................................................66

Contents