Alphabetical Index

Alcohol vs Gas...................................................25

Alternator.....................................................26, 27

Antifouling.........................................................11

Autopilot.............................................................28

Batteries..............................................................26

Battery..........................................................27, 28

Bleeding Fuel ine.......................................13, 14

Boom............................................8, 16, 17, 19, 20

Charging.................................................26, 27, 28

Cleats............................................................11, 17

Cockpit Drains....................................................11

Deck Fittings................................................11, 12

Derusting Keels..................................................11

Electrics....................................................2, 26, 27

Engine Maintenance...............................14, 21, 27

Engine Manuals............................................14, 28

Engines.....................................................2, 13, 14

Exhaust...............................................................15

Foresail...........................................................8, 16

Fuel ........................................................13, 14, 15

Furling Gear.......................................................17

Galley.................................................................24

Gas..........................................................15, 24, 25

Grab Rail............................................................11

Halyard.......................................7, 8, 9, 19, 20, 21

Hatches...............................................2, 12, 22, 23

Heater.................................................................25

History..................................................................6

Hull...........................................................2, 10, 12

Instruments...............................................2, 26, 27

Keels.............................................................11, 12

azyjacks............................................................21

ighting........................................................27, 28

og...............................................................27, 28

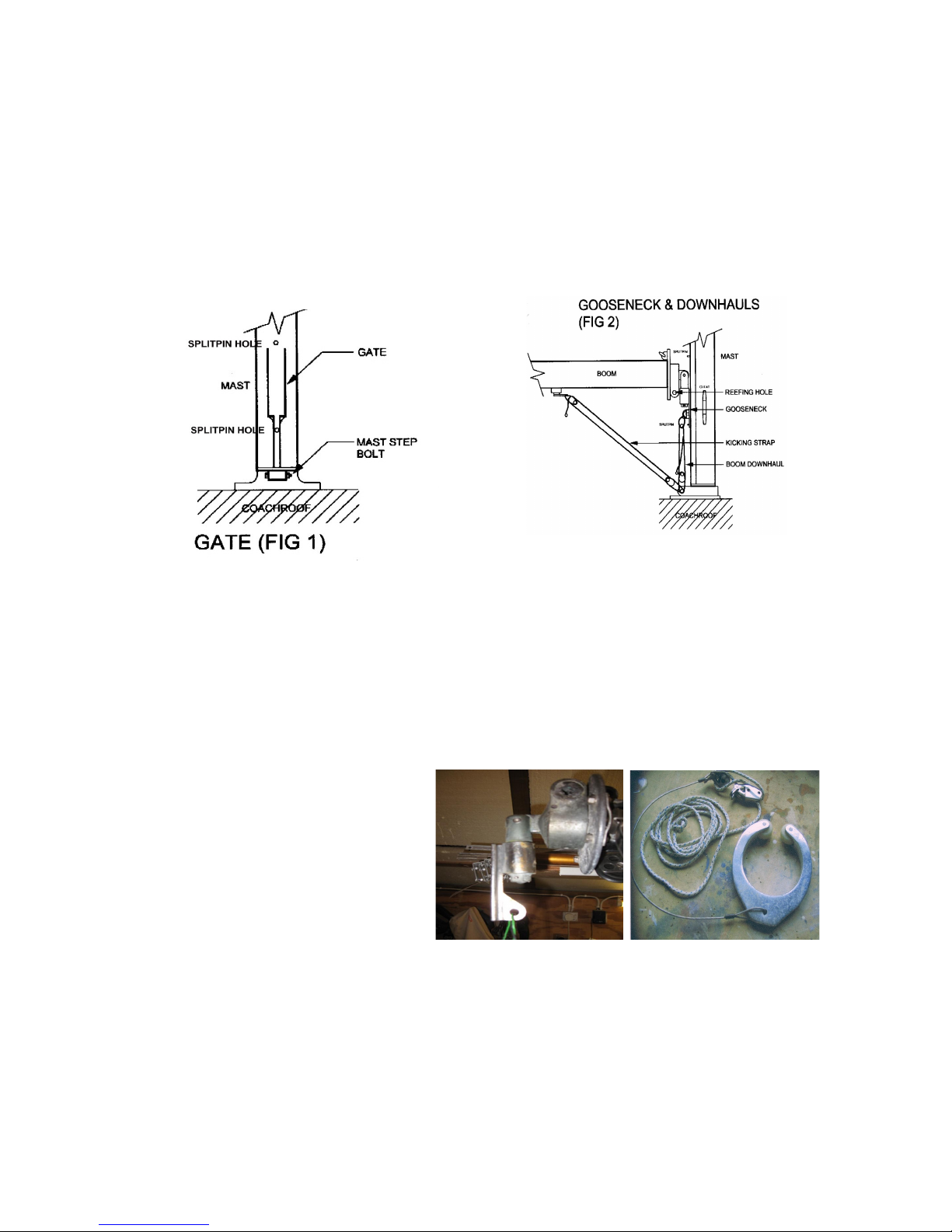

owering Mast.............................................12, 17

Mainsail....................................................8, 17, 21

Manuals........................................................14, 28

Mast............................................2, 6, 7, 12, 16, 17

Mast and Rigging.................................................7

Mast Heel...........................................................17

NASA og..........................................................28

Oil eak..............................................................15

Outboard.................................................14, 27, 28

Overheating............................................13, 14, 15

Plastimo........................................................17, 21

Propeller.............................................................14

Propeller Bearing................................................15

Reefing.......................................16, 17, 19, 20, 21

Rigging Diagram............................................7, 19

Rudder......................................................2, 10, 18

Running Rigging......................................2, 16, 19

Safety................................................................2, 7

Saildrive..................................................11, 14, 15

Seal.................................11, 12, 14, 15, 18, 22, 23

Skeg..........................................................2, 10, 18

Solar Panel..........................................................28

Spirit vs Gas.......................................................25

Stanchion......................................................11, 12

Standing Rigging....................................2, 6, 7, 16

Switch Panel.................................................27, 28

Tiller.............................................................14, 18

Upholstery..........................................................25

VHF..........................................................9, 27, 28

Water Inlet....................................................14, 15

Water Pump........................................................15

Water Tank..........................................................25

Winches..............................................................12

Wind Generator..................................................28

Windows.........................................................2, 22

Wiring.....................................................26, 27, 28

.............................................................................2

3