140528/2 Page 2of 32

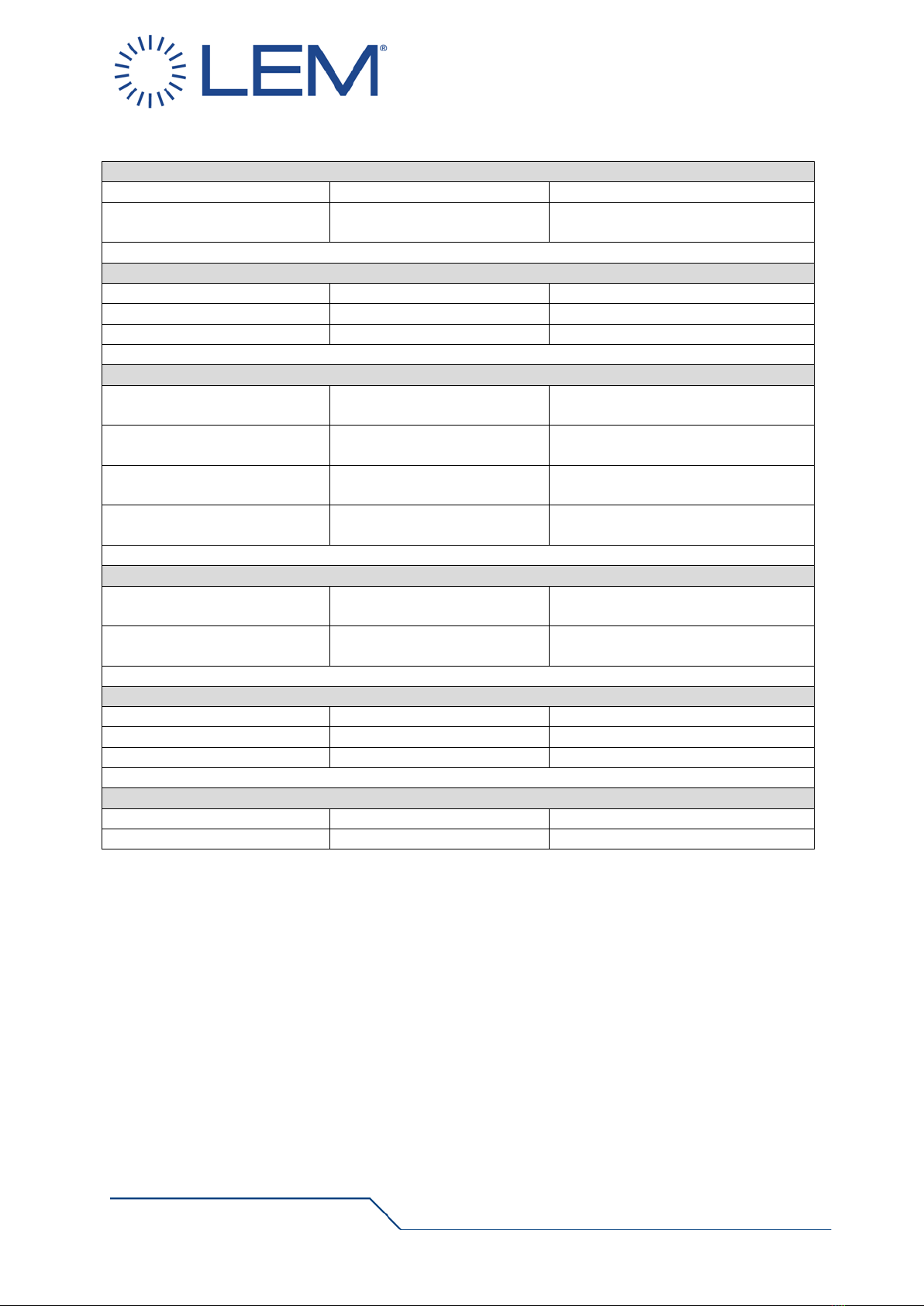

TABLE OF CONTENTS

TABLE OF CONTENTS .......................................................................................................................... 2

LIST OF FIGURES .................................................................................................................................. 3

LIST OF TABLES .................................................................................................................................... 3

DOCUMENT INFORMATION.................................................................................................................. 3

INTRODUCTION ..................................................................................................................................... 4

RECEIVING AND UNPACKING.............................................................................................................. 6

GENERAL SPECIFICATIONS FOR RACK ELECTRONICS.................................................................. 7

1Compliance with regulations............................................................................................................ 8

2Usage precautions and recommendations...................................................................................... 9

2.1 Terms and symbols ................................................................................................................. 9

2.2 General use and wear ............................................................................................................. 9

2.3 Grounding considerations........................................................................................................ 9

2.4 Fuses ....................................................................................................................................... 9

2.5 Precautions for use................................................................................................................10

3Quick start...................................................................................................................................... 11

3.1 System overview ................................................................................................................... 11

3.2 Setting up............................................................................................................................... 12

4Introduction .................................................................................................................................... 14

4.1 Main features ......................................................................................................................... 14

4.2 Standard transducer heads ................................................................................................... 14

4.3 Custom transducer heads ..................................................................................................... 15

4.4 Voltage output module........................................................................................................... 15

4.5 Current conversion ratio and programmability ......................................................................15

4.6 Front ...................................................................................................................................... 17

4.7 Rear ....................................................................................................................................... 18

4.8 Transducer head ................................................................................................................... 19

5Installation...................................................................................................................................... 20

5.1 Mounting requirements for the electronics unit .....................................................................20

5.2 Mounting requirements for the transducer heads..................................................................20

5.3 Grounding the transducer head.............................................................................................21

5.4 Installation.............................................................................................................................. 21

6Offset adjustment .......................................................................................................................... 22

6.1 Adjusting the current offset....................................................................................................22

7. I/0-ports.......................................................................................................................................... 23

7.1 Analog Out connector ............................................................................................................ 23

7.2 4 mm “Banana” Current Output terminals ............................................................................. 23

7.3 Status/Interlock connector ..................................................................................................... 24

8Absolute maximum ratings ............................................................................................................ 26

9Sweep function during overload status ......................................................................................... 26

10 Thermal protection..................................................................................................................... 26

11 Over current protection - Electrical specifications .....................................................................26

12 Transducer head connector....................................................................................................... 28

13 Operating instructions................................................................................................................28

13.1 Switching on power ............................................................................................................... 28

13.2 Using the ITZ FLEX ULTRASTAB in current mode...............................................................28

13.3 Connecting directly to a current measuring device ...............................................................29

13.4 Connecting to an external burden resistor (current output)...................................................30

13.5 Connecting the ITZ FLEX ULTRASTAB to a DMM or high impedance amplifier (voltage

output) 30

14 Theory of operation ................................................................................................................... 31

14.1 Basic principle of ITZ FLEX ULTRASTAB current transducers ...........................................31

15 Maintenance .............................................................................................................................. 32