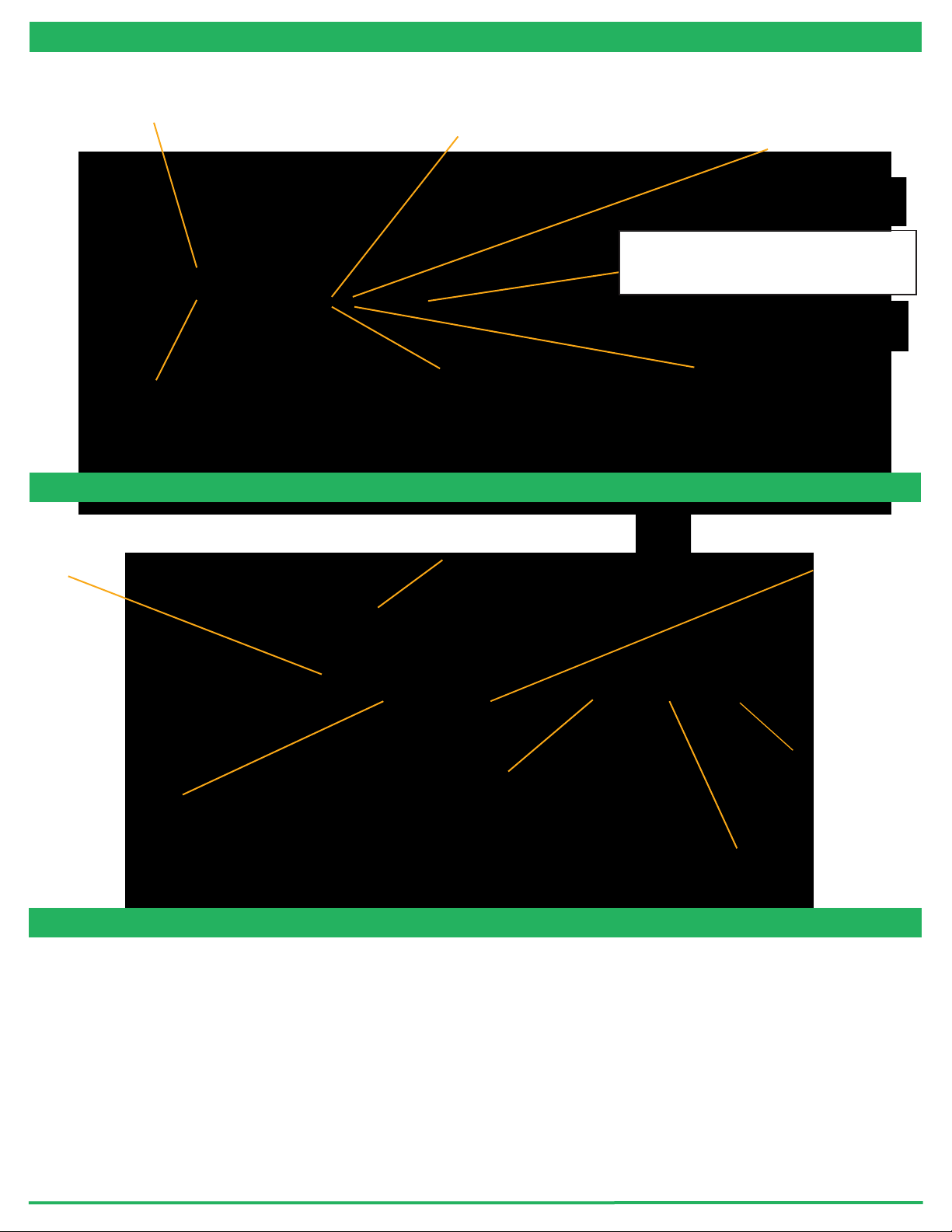

CONNECTING YOUR SYSTEM - FRONT OF UNIT

www.prior.com

POS MON connector Analogue

position monitor output BNC

connector(s)

Single ended output(s).

ANA I/P” connector

Signal used to control the stage position

Analogue command input

BNC connector(s)

Single ended output(s).

Earth Stud - M4 threaded stud

Provides additional ground connection to reduce interference of

background electrical noise. Do not raise above 0V ground potential

PWR Connector

Provides power to controller electronics.

4 pin mini-DIN with screen Input

+24V dc ±0.75V @ 5A

ONLY connect an approved power supply.

Digital I/O connector

Provides digital inputs and outputs for interfacing controller

to external equipment.

TRIG inputsand outputs

IN_POS Output

Stepped input and outputs

25 pin D-type socket; 5V TTL input/output

MUST use shielded cable.

Ethernet Connector

for upgrading firmware

USB type B connector

Used to communicate with a

computer running

Nanobench or using using

DLL commands

SYNC IN/OUT connector

Provides RS232C connection with

connected computer using supplied

gender changer adapter.

Power Indicator LED

Indicates the power status and controller ready

RED steady = Controller configuring/not ready (can

take up to 30 seconds).

GREEN steady = Controller powered and ready for

operation

CLOSED INDICATOR LED

Indicates the status of control Loop

OFF = Stage NOT connected

ORANGE = Stage settings being loaded on connection

RED = Controller operating in OPEN loop mode

GREEN = Controller operating in CLOSED loop mode

YELLOW = Controller servo output frozen

COMS Indicator LED

Indicates status of communications with connected

computer.

Not lit = No communications taking place.

GREEN lit or flashing = Communications active

IN POS Indicator LED

Indicates the status of the stage position in CLOSED

loop mode.

OFF = Stage has not reached desired position.

ORANGE = Stage settings being loaded on connection

GREEN = Stage has reached the desired position

Nano Mechanism Connector – connect the OP400

to this position.

NOTE High Voltage present on connector – up to

160VDC

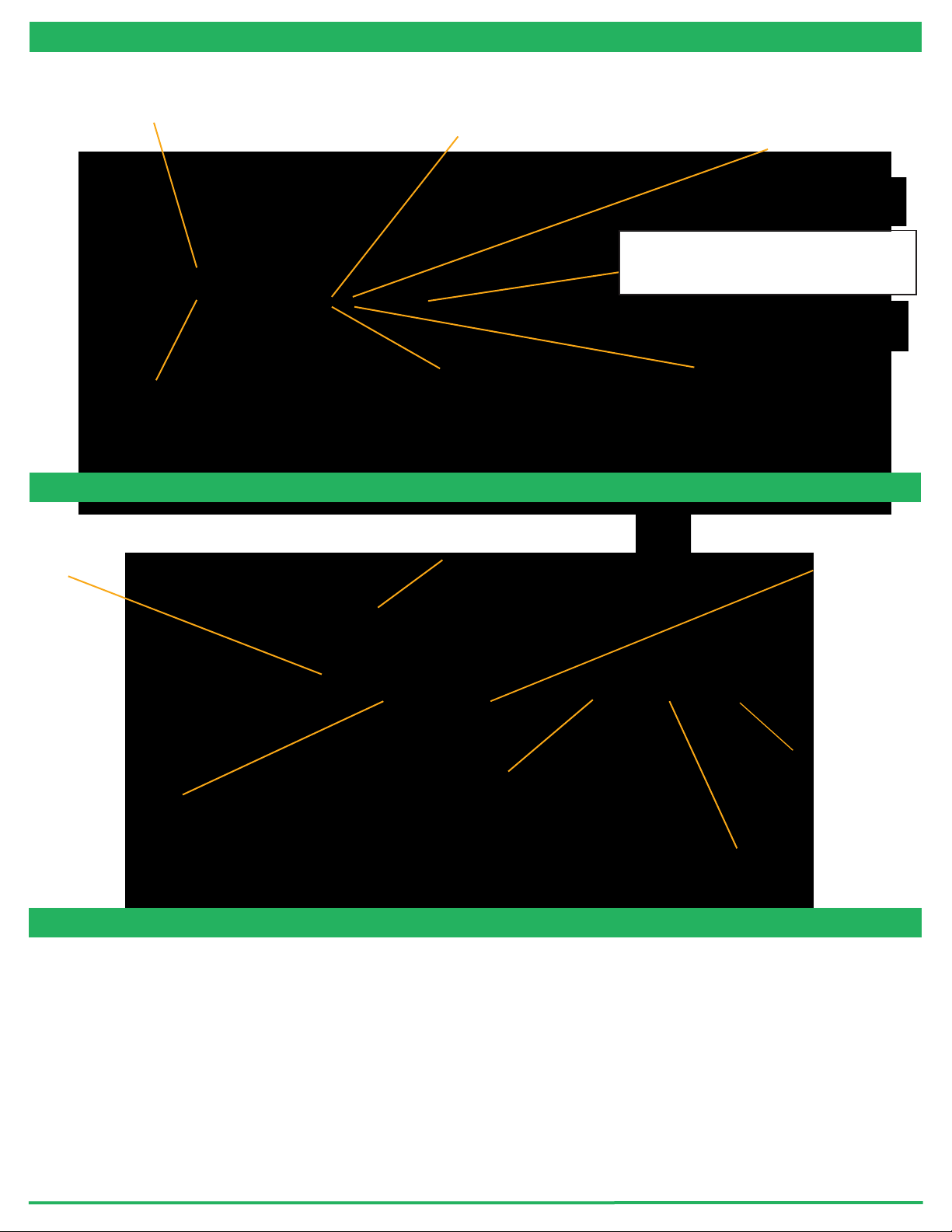

CONNECTING YOUR SYSTEM - BACK OF UNIT

TURNING ON YOUR SYSTEM

1. Once the stage is mounted, connect it to the controller ensuring that the connector screws are tightened to the controller lock

posts. On powerup, the controller will always move the stage across its range to carry out auto-calibration. It is important

to ensure that there is sufficient clearance between the lens, sample and illumination to allow this to take place. If the

temperature or load change significantly the stage can 'clip at one end of the travel. Should this happen restart your system to

allow autocalibration; this rebalances the stage so that the closed loop range is centred within the open loop range.

2. Connect Power to controller and the analogue input and/or USB as required.

3. Switch ON controller using switch on rear panel. After approx. 30 seconds, the relevant stage channel should show two green

lights (CLOSED and IN-POS). This indicates the stage is operating in the CLOSED loop mode and IN-POS LED indicates stage

has reached position within a pre-defined band.

4. The analogue input and POS MON output is 0V to +10V giving a scale factor of 40µm/volt. The analogue input is enabled by

default.

5. The system has 8 memory positions for PID settling (accessible via the USB interface). The default setting is for objective loads

from 150g to 500g. An optimised setting providing a faster settle time for loads up to 350g can by selected using Nanobench. The

next section demonstrates how to change to other settings.