5

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL ALIGN™ MULTI-GAS GENERATOR

Do not install and operate this equipment until the safety information and instructions in this user guide have

been read and understood by all personnel concerned.

USER RESPONSIBILITY:

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN

OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE, AND VOID

THE SAFTEY CERTIFICATION.

This document and other information from Parker Hannin Corporation, its subsidiaries and authorized dis-

tributors provide product or system options for further investigation by users having technical expertise.

The user, through its own analysis and testing, is solely responsible for making the nal selection of the

system and components and assuring that all performance, endurance, maintenance, safety and warning

requirements of the application are met. The user must analyze all aspects of the application, follow appli-

cable industry standards, and follow the information concerning the product in the current product catalogue

and in any other materials provided from Parker or its subsidiaries or authorized distributors.

To the extent that Parker or its subsidiaries or authorized distributors provide component or system options

based upon data or specications provided by the user, the user is responsible for determining that such

data and specications are suitable and sufcient for all applications and reasonably foreseeable uses of

the components or systems.

Only competent personnel trained, qualied, and approved by Parker Hannin should perform installation,

start-up, service and repair procedures.

This equipment is for indoor use only. Do not operate outdoors.

Nitrogen is nontoxic and largely inert. It can act as a simple asphyxiant by displacing oxygen in air. Inhala-

tion of nitrogen in excessive concentrations can result in unconsciousness without any warning symptoms

such as dizziness and fatigue.

The generator should be installed in an area with adequate ventilation to reduce the ammability of the oxy-

gen-rich permeate stream. The system should not be installed in an area where the permeate stream poses

the risk of explosion or combustion.

Use of the equipment in a manner not specied within this user guide may result in an unplanned release of

pressure, which may cause serious personal injury or damage.

When handling, installing, or operating this equipment, personnel must employ safe engineering practices

and observe all related regulations, health & safety procedures, and legal requirements for safety.

Never place liquids on top of the generator.

Do not store anything on top of the generator.

Never sit or climb on top of the generator.

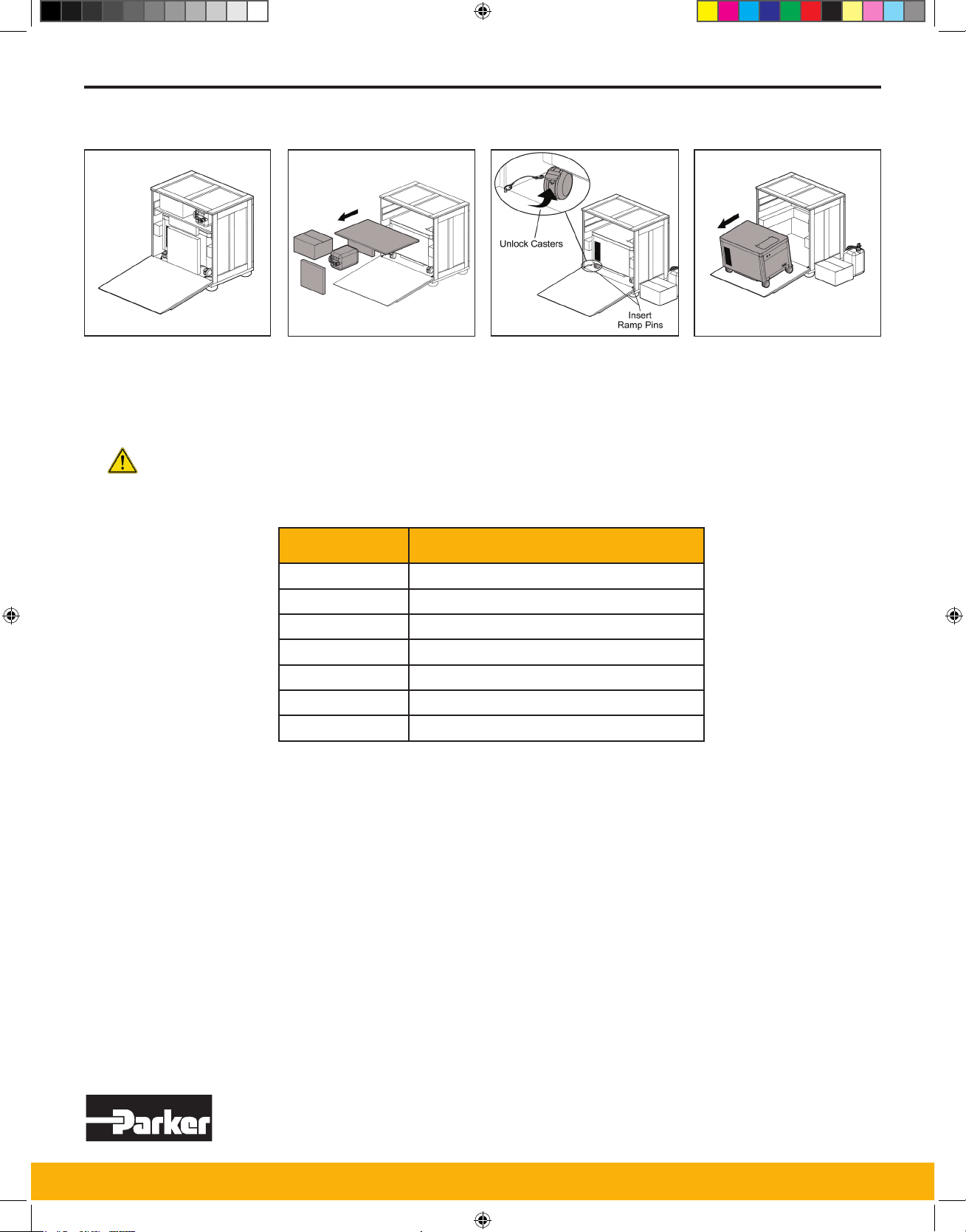

Ensure casters are locked before starting up the generator.

Ensure that the equipment is depressurized and electrically isolated, prior to carrying out any of the sched-

uled maintenance instructions specied within this user guide.

2. SAFETY INFORMATION

IOM_PKR_Align Multi-Gas Generator_022021.indd 5IOM_PKR_Align Multi-Gas Generator_022021.indd 5 2/17/2021 1:11:40 PM2/17/2021 1:11:40 PM