Pg. 1

Table of Contents

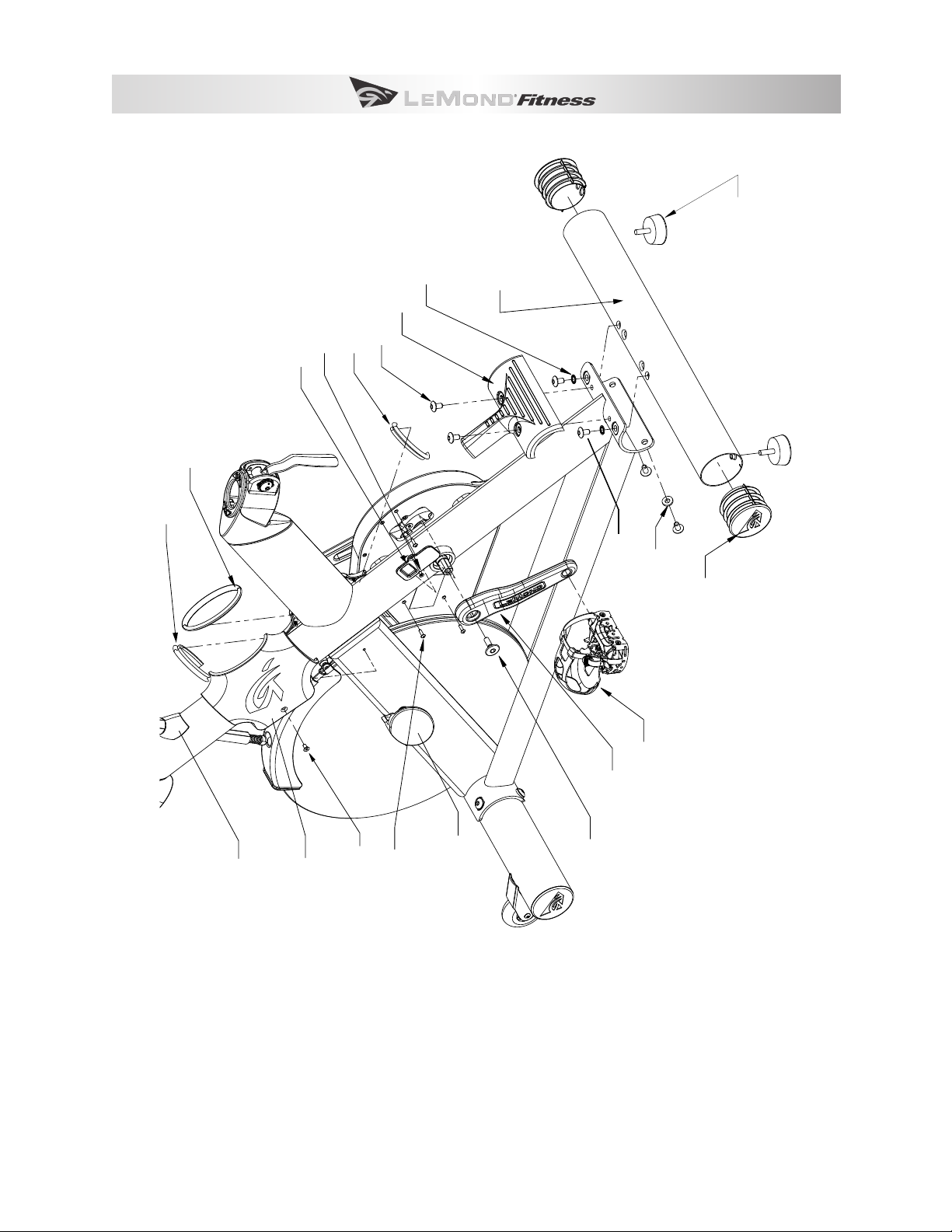

Exploded Diagrams................................................................................ 2

Tool List ..........................................................................................10

Installation Check List...........................................................................11

Stabilizer Bars.....................................................................................11

Pedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Handlebar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Seat Slider ........................................................................................11

Water Bottle Holder ...............................................................................11

Maintenance Schedule...........................................................................12

Troubleshooting ..................................................................................13

Disassembly / Adjustment / Assembly ...........................................................15

Handlebar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pedals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Crank Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Belt Cover ........................................................................................18

Drive Belt .........................................................................................19

Drive Belt Tension ......................................................................................... 20

Bottom Bracket ...................................................................................21

Flywheel..........................................................................................22

Pillow Block ................................................................................................23

Brake Assembly ..................................................................................24

Fender...........................................................................................25

Brake Pad..................................................................................................26

Adjustment Handles ..............................................................................27