Page 10

Plumbing

Field refrigerant piping consists of liquid and suction lines

exiting the condensing unit. You may bring piping into the

unit through either side. Remove the knockouts on the mul

lions and install the provided rubber grommets into the pip

ing holes. Remove the plugs from the liquid and suction

lines. Refer to table 1 for fieldfabricated refrigerant line

sizes for runs up to 50 linear feet (15 m).

Table 1

Refrigerant Line Sizes for Runs Up to 50 Linear Feet

Unit Liquid Line Suction Line

HS29−072 5/8 in.

(16 mm)

1−1/8 in.

(29 mm)

HS29−090 5/8 in.

(16 mm)

1−3/8 in.

(35 mm)

HS29−120 5/8 in.

(16 mm)

1−3/8 in.

(35 mm)

Refrigerant Line Brazing Procedure

1 − Cut the end of the refrigerant line square, keep it round,

protect it from nicks or dents, and debur it. (I.D. and

O.D.)

2 − Wrap a wet cloth around the liquid and suction valve

body when brazing to prevent possible heat damage to

the valve core and port.

3 − In the liquid line, install the filter drier (provided with the

unit) in an accessible area as close as possible to the

expansion device.

Refrigerant Line Limitations

You may install the unit in applications that have line set

lengths of up to 50 linear feet (15 m) with refrigerant line

sizes as outlined in table 1 (excluding equivalent length of

fittings). Size refrigerant lines from 50 to 100 linear feet (15

to 30 m) according to the the following section. Line lengths

greater than 100 feet (30 m) are not recommended.

Maximum suction lift must not exceed 70 linear feet (21 m)

and the maximum liquid head must not exceed 50 linear

feet (15 m).

When line lengths exceed 50 feet (15 m), install a liquid line

solenoid at the evaporator coil. In addition, use only expan

sion valves (RFC and captube expansion devices are not

acceptable).

NOTE − When refrigerant line solenoid valves are installed,

velocities should not exceed 300 fpm (1.5 m/s) in order to

avoid liquid line hammer.

Because additional refrigerant is necessary to fill the lines,

the likelihood of slugging is greatly increased if the lines are

over 50 feet (15 m). An incremental increase in liquid line

size results in a 40 to 50 percent increase in liquid refriger

ant to fill the line. Therefore, use the smallest liquid line size

possible.

All units are equipped with a low ambient (head pressure)

control to allow for cooling at an ambient condition of 0°F

(−18°C).

Pipe Sizing, Line Layout, and Design

[Line Set Lengths of 50 − 100 Linear Feet

(15 − 30 m)]

Create a a sketch of the system that shows the relative

locations of the condensing unit and the evaporator as well

as the length of the following:

D each piping segment

D elbows

D tees

D valves

Use this information to determine the equivalent length of

the piping run. Also, take note of any difference in the

elevation between the outdoor and indoor units. You must

consider vapor and liquid lift so that you can properly size

the pipe.

Liquid Line Function and Design

The liquid line must convey a full column of liquid from the

condenser to the metering device at the evaporator coil

without flashing. In order to ensure this, you must consider

the liquid line pressure drop and the pressure across the

expansion device and distributor.

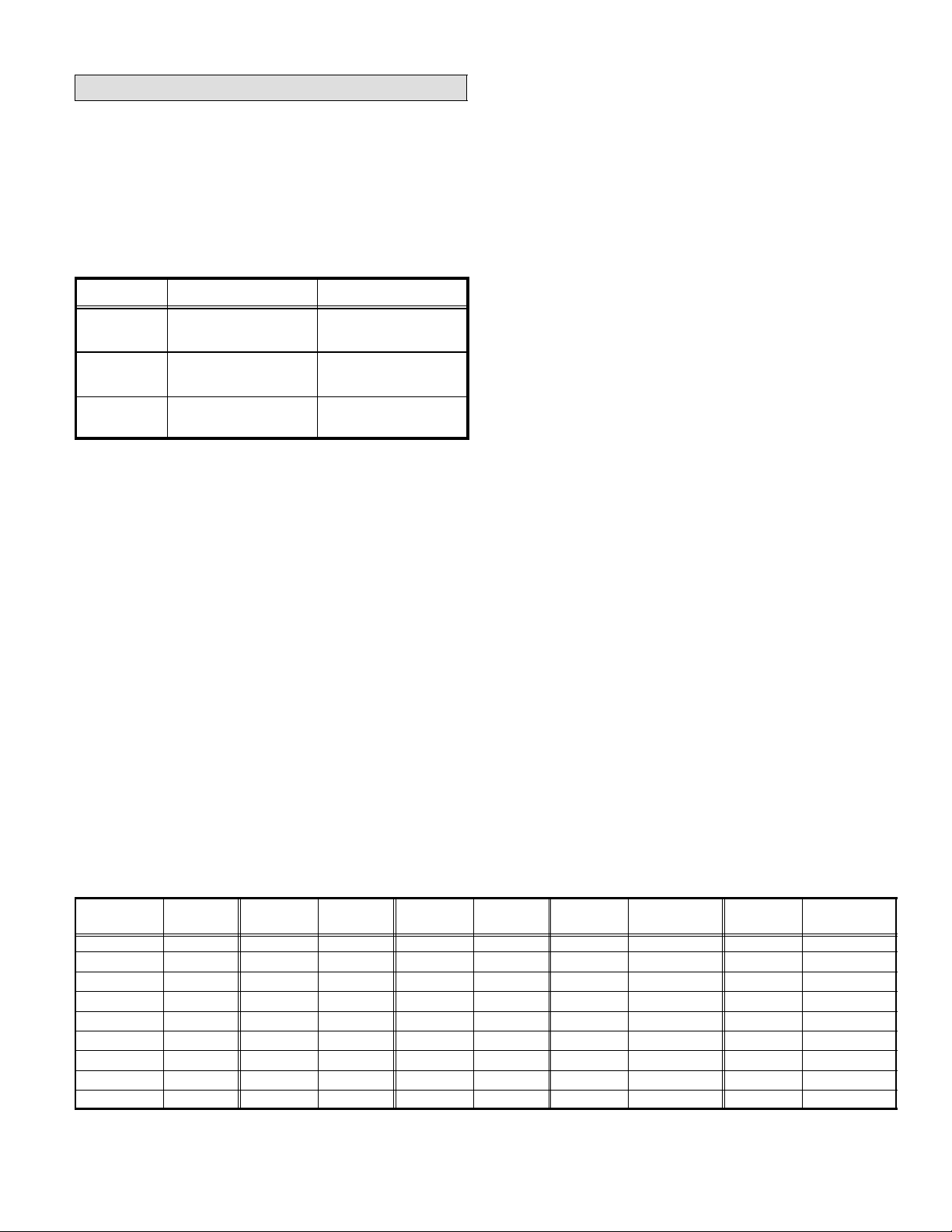

Table 2

HCFC22 Saturation Temperatures

(Condensing Temperatures at Different Pressures)

Temp.

°F (°C)

Pressure

psig (kPa)

Temp.

°F (°C)

Pressure

psig (kPa)

Temp.

°F (°C)

Pressure

psig (kPa)

Temp.

°F (°C)

Pressure

psig (kPa)

Temp.

°F (°C)

Pressure

psig (kPa)

−40 (−41) 0.6 (4.13) 18 (−8) 41.1 (283) 36 (2) 63.3 (436) 75 (24) 133.4 (920) 120 (49) 262.5 (1810)

−30 (−34) 4.09 (28.1) 20 (−7) 43.3 (299) 38 (3) 66.1 (456) 80 (27) 145.0 (1000) 125 (52) 280.7 (1936)

−20 (−28) 10.2 (70.3) 22 (−6) 45.5 (314) 40 (4) 69.0 (476) 85 (29) 157.2 (1084) 130 (54) 299.7 (2066)

−10 (−23) 16.6 (114) 24 (−4) 47.9 (330) 45 (7) 76.6 (528) 90 (32) 170.0 (1172) 135 (57) 319.6 (1514)

0 (−18) 24.1 (166) 26 (−3) 50.3 (347) 50 (10) 84.7 (584) 95 (35) 183.6 (1287) 140 (60) 340.3 (2346)

10 (−12) 32.9 (227) 28 (−2) 52.7 (363) 55 (13) 93.3 (643) 100 (38) 197.9 (1364) 145 (63) 362.0 (2496)

12 (−11) 34.9 (241) 30 (−1) 55.2 (381) 60 (16) 102.4 (706) 105 (41) 212.9 (1468) 150 (66) 384.6 (2651)

14 (−10) 36.9 (254) 32 (0) 57.8 (399) 65 (18) 112.2 (774) 110 (43) 228.6 (1576) 155 (68) 406.3 (2801)

16 (−9) 39.0 (269) 34 (1) 60.5 (417) 70 (21) 122.5 (841) 115 (46) 245.2 (1691) 160 (71) 433.3 (2987)