Page 6

Use the following procedures to congure the unit for hor-

izontal left-hand discharge operations:

1 - Before operating the unit, remove access panels

and the horizontal drip shield (-060 model) and the

corrugated padding between the blower and coil

assembly. Discard the corrugated padding.

2 - Pull the coil assembly from unit. Pull o the

horizontal drain pan.

3 - Remove the drain plugs from back drain holes on

horizontal drain pan and reinstall them on front

holes.

IMPORTANT

After removal of drain pan plug(s), check drain hole(s)

to verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has fallen

into the drain pan during installation that may plug up the

drain opening.

4 - Rotate drain pan 180º front-to-back and install it on

the opposite side of the coil.

5 - Remove screws from top cap. Remove horizontal

drip shield screw located in the center of the back

coil end seal as illustrated in gure 4 on page 5.

6 - Rotate horizontal drip shield 180º front-to-back.

7 - Remove plastic plug from left hole on coil front

end seal and reinstall plug in back hole. Reinstall

horizontal drip shield screw in front coil end seal.

Drip shield should drain downward into horizontal

drain pan inside coil.

HORIZONTAL DRIP SHIELD (-060 MODEL)

DOWN-FLOW RAIL FRONT EDGE OF HORIZONTAL

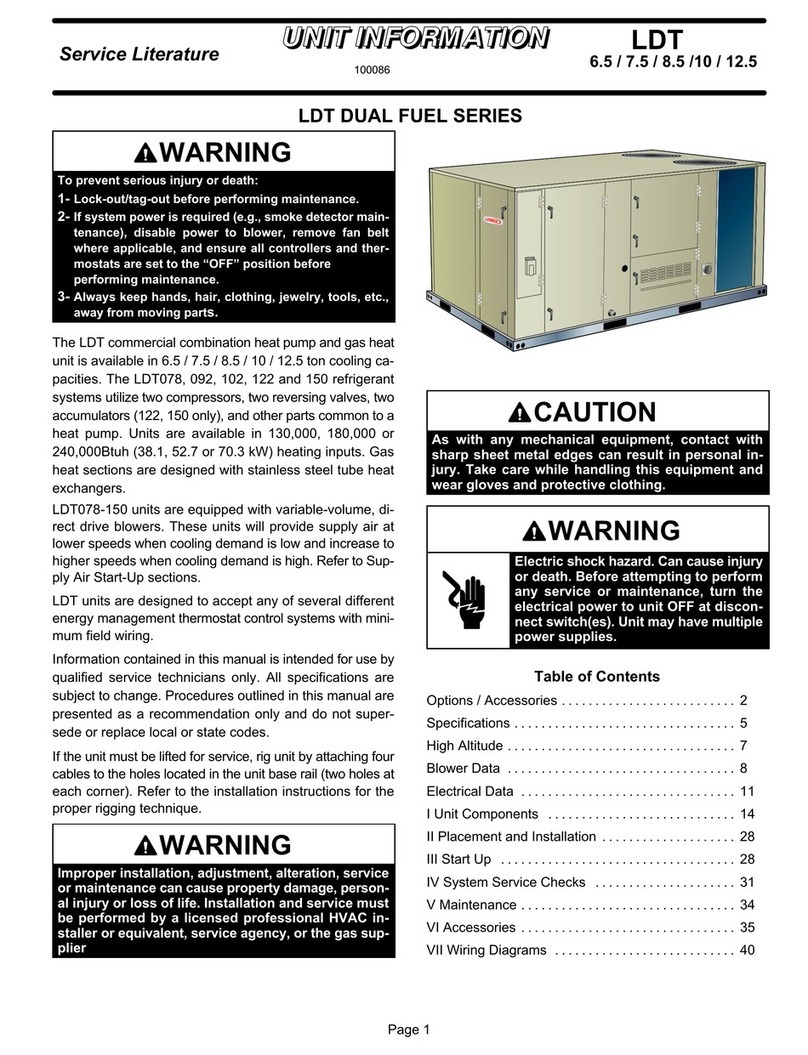

FIGURE 5. Left-Hand Discharge Conguration

8 - Rotate top cap 180º front-to-back and align with

unused screw holes. Holes must align with front and

back coil end plates. The top cap has a 45º bend on

one side and a 90º bend on the other. The 90º bend

must be on the same side as the horizontal drain

pan as illustrated in gure 4 on page 5.

NOTE – Be very careful when reinstalling the screws into

the coil end plate engaging holes. Misaligned screws may

damage the coil.

9 - From the upow position, ip cabinet 90º to the

left and set into place. Replace blower assembly.

Secure coil in place by bending down the tab on the

cabinet support rail as illustrated in gures 4 and 5.

10 - Install the horizontal shield (-060 model) on the

front edge of the horizontal drain pan as illustrated

in gure 5 on page 6.

NOTE – For horizontal applications in high humidity ar-

eas, remove the downow rail closest to the drain pan. To

remove rail, remove screw from rail at back of unit and at

cabinet support rail. Remove downow rail then replace

screws. Also, seal around the exiting drain pipe, liquid and

suction lines to prevent inltration of humid air.

11 - Knock out drain seal plate from access door. Secure

plate to cabinet front ange with screw provided.

12 - Flip access door and replace it on the unit.

13 - Set unit so that it is sloped 1/4ʺ toward the drain

pan end of the unit. Connect return and supply air

plenums as required using sheet metal screws.

14 - If suspending the unit, it must be supported along the

entire length of the cabinet. If using chain or strap,

use a piece of angle iron or sheet metal attached

to the unit (either above or below) so that the full

length of the cabinet is supported. Use securing

screws no longer than 1/2ʺ to avoid damage to coil

or lter, as illustrated in gure 3 on page 5. Connect

return and supply air plenums as required using

sheet metal screws.

DOWNFLOW APPLICATION

NOTE – If downow application is required, separately

order kit number 83M57 and install per kit’s instructions.

Also use metal or class I supply and return air plenums.

Use the installation instruction provided with the downow

kit.

IMPORTANT

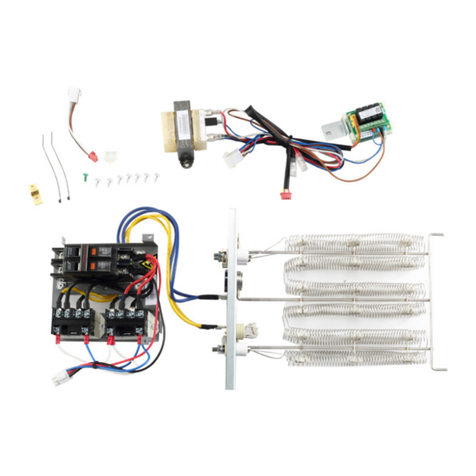

If electric heat section with circuit breakers (ECB29/

ECB31) is installed in a CBA27UHE unit in a downow

application, the circuit breakers must be rotated 180°

to the UP position. See ECB29/ECB31 installation

instructions for more details.

Brazing Connections

IMPORTANT

To prevent the build-up of high levels of nitrogen when

purging, it must be done in a well-ventilated area. Purge

low-pressure nitrogen (1 to 2 psig) through the refrigerant

piping during brazing. This will help to prevent oxidation

and the introduction of moisture into the system.

All coils are equipped with a factory-installed, internally

mounted check/expansion valve.

The air handler’s coil line sizes are listed in table 2. Use

Lennox L15 (sweat) series line sets (refer to the outdoor

unit Product Specications (EHB) for proper size, type

and application). For eld-fabricated refrigerant lines, see

the piping section of the Lennox Unit Information Service

Manual.