Page 5

ACBX32CM SERIES

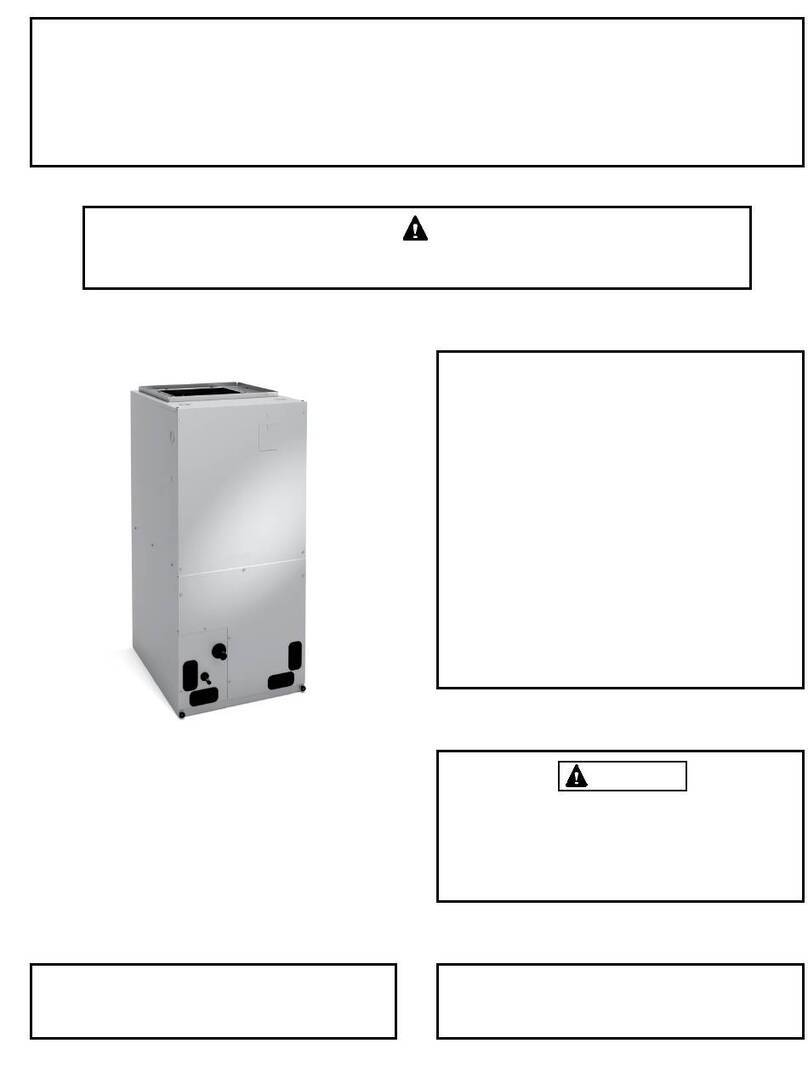

FRONT VIEW END VIEW

ANGLE IRON OR

SHEET METAL

ELECTRICAL INLET

CLEARANCE 4 IN. (102 MM)

1/2 IN.

SCREWS

MAX.

Figure 3. Suspending Horizontal Unit

CAUTION

When removing the coil, there is possible danger of

equipment damage and personal injury. Be careful

when removing the coil assembly from a unit

installed in right−or left−hand applications. The coil

may tip into the drain pan once it is clear of the

cabinet. Support the coil when removing it.

HORIZONTAL RIGHT−HAND DISCHARGE

APPLICATION

Use the following procedures to configure the unit for

horizontal right−hand discharge operations:

NOTE −For horizontal applications, a secondary drain

pan is recommended. Refer to local codes.

1. Remove access panels. Remove corrugated padding

from the space between the blower and coil assembly.

2. No further adjustment is necessary. Set unit so that it is

sloped 1/4 inch toward the drain pan end of the unit as

illustrate in figure 2 on page 4.

3. If the unit is to be suspended, it must be supported

along the entire length of the cabinet as illustrated in

figure 3. If a strap is used, attach a piece of angle iron

or sheet metal to the unit (either above or below) so

that the full length of the cabinet is supported. Use

securing screws which are no longer than 1/2 inch to

avoid damaging the coil or filter. Connect the return

and supply air plenums as required using sheet metal

screws.

HORIZONTAL LEFT−HAND DISCHARGE

APPLICATION

Use the following procedures to configure the unit for

horizontal left−hand discharge operations:

NOTE −For horizontal applications, an secondary drain

pan is recommended. Refer to local codes.

Remove access panels. Remove corrugated padding from

the space between the blower and coil assembly before

operation.

1. Remove coil assembly from unit and remove the

horizontal drain pan as illustrated in figure 4, detail A

on page 6.

2. Remove drain plugs from back drain holes on

horizontal drain pan and reinstall them on front holes.

IMPORTANT

After removal of drain pan plug(s), check drain

hole(s) to verify that drain opening is fully open and

free of any debris. Also check to make sure that no

debris has fallen into the drain pan during installa-

tion that may plug up the drain opening.

3. Rotate the drain pan 180° front to back and install it on

the opposite side of coil.

4. Remove screws from top cap. Remove horizontal drip

shield screw located in the center of the back coil end

seal as illustrated in figure 4, details B and C on page

6.

5. Rotate horizontal drip shield 180° front to back.

6. Remove plastic plug from left hole on coil front end

seal and reinstall plug in back hole. Reinstall horizontal

drip shield screw in front coil end seal. Drip shield

should drain downward into horizontal drain pan inside

coil.

7. Rotate top cap 180° front to back and align with

unused screw holes. Holes must align with front and

back coil end plates. Note that top cap has a 45° bend

on one side and 90° bend on the other. The 90° bend

must be on the same side as the horizontal drain pan

as illustrated in figure 4 on page 6.

NOTE −Be very careful when you reinstall the screws into

coil end plate engaging holes. Misaligned screws may

damage the coil.

8. From the upflow position, flip cabinet 90° to the left and

set into place. Replace blower assembly. Secure coil

in place by bending down tab on cabinet support rail

as illustrated in figure 5 on page 6.

NOTE −For horizontal applications in high humidity

areas, seal around the exiting drain pipe, liquid line and

suction line to prevent infiltration of humid air.

9. Knock out drain seal plate from access door. Secure

plate to cabinet front flange with screw provided.

10. Flip access door and replace it on the unit.

11. Set unit so that it is sloped 1/4 inch toward the drain

pan end of the unit. Connect return and supply air

plenums as required using sheet metal screws.

12. If the unit is to be suspended, it must be supported

along the entire length of the cabinet as illustrated in

figure 3 on page 5. If using a chain or strap, attach a

piece of angle iron or sheet metal to the unit (either

above or below the unit), so that the full length of the

cabinet is supported. Use securing screws which are

no longer than 1/2 inch to avoid damaging the coil or

filter. Use sheet metal screws to connect the return

and supply air plenums.