Page 3

Important Directions

1 - Keep the furnace area c ear and free of combustib e

materia , gaso ine, and other f ammab e vapors and iqĆ

uids. If insta ed in an insu ated area, furnace must be

kept free of insu ating materia . Insu ating materia may

be combustib e. Inspect furnace venting system to

make sure it is in p ace, physica y sound, and without

ho es, corrosion, or b ockage. Inspect furnace return

air duct connection to ensure duct is sea ed to the furĆ

nace and terminates outside the space containing the

furnace. Inspect the physica support of the furnace to

guarantee that it is sound without sagging, cracks or

gaps around base and it maintains sea between base

and support.

2 - DO NOT obstruct air f ow to unit. Unit must receive an

unobstructed f ow of combustion and venti ating air.

3 - DO NOT store ch orine or f uorine products near unit or

introduce these products into the combustion air.

These products can cause furnace corrosion.

4- DO NOT raw return air from a room where this

furnace, or any other gas appliance (ie., a water

heater), is installe . When return air is drawn from a

room, a negative pressure is created in the room. If a

gas app iance is operating in a room with negative

pressure, the f ue products can be pu ed back down

the vent pipe and into the room. This reverse f ow of

the f ue gas may resu t in incomp ete combustion and

the formation of carbon monoxide gas. This toxic gas

might then be distributed throughout the house by

the furnace duct system.

Your furnace is a gas appliance. It is critica that the gas

supp ied to the unit be comp ete y burned to avoid the proĆ

duction of carbon monoxide gas. Comp ete combustion

of the gas requires, but is not imited to, correct gas presĆ

sure and gas f ow rate, adequate combustion air, and

proper venting.

WARNING

Carbon monoxi e gas is invisible, o orless, an

toxic.

Exposure to this gas can cause persona injury and

even death to a occupants, inc uding pets. Any item

that is powered by or gives off heat from a combustion

process (inc uding awn mowers, automobi es, and fireĆ

p aces) has the potentia to produce carbon monoxide

gas. Because of this, Lennox recommen s the use of

a carbon monoxi e etector in your home, even if

you o not own gas appliances. Re iab e detectors

are avai ab e at reasonab e retai prices. Contact your

independent Lennox dea er for more detai s about this

investment in your safety.

Your furnace is designed to meet standards set by nationĆ

a agencies, and to operate safe y when proper y insta ed

and maintained. However, the unit's performance can be

great y impacted by the individua insta ation and the opĆ

erating environment. It is your responsibi ity to ensure

that this app iance is maintained. Proper maintenance is

critica for your safety and the satisfactory operation of the

product. Lennox strongly recommen s annual inĆ

spection an maintenance of this appliance. Contact

your independent Lennox dea er for an inspection by a

qua ified service technician.

Lighting Information an Operation

WARNING

If you o not follow these instructions exactly, a fire

or explosion may result causing property amage,

personal injury or loss of life.

BEFORE LI HTIN smell all around the appliance

area for gas. Be sure to smell next to the floor because

some gas is heavier than air and will settle on the

floor.

Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or turn

by hand, do not try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

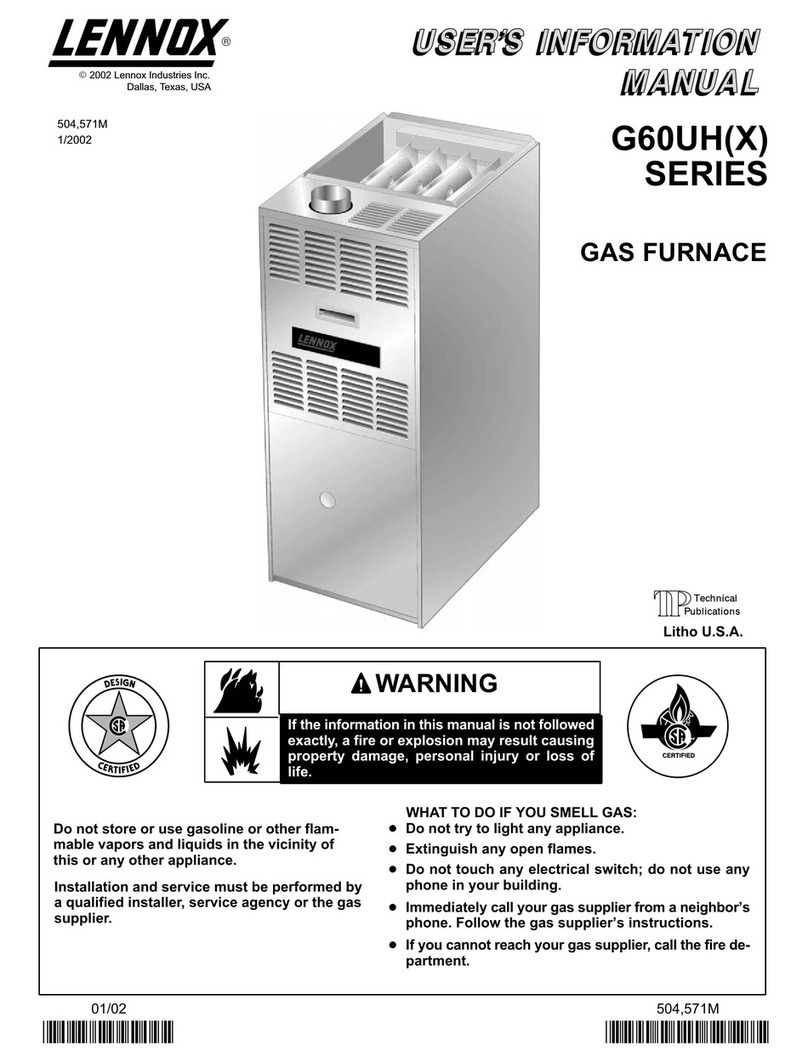

To place 80UHG furnace into operation:

80UH units are equipped with an electronic ignition

system. Do not attempt to manually light burners on

these furnaces. Each time thermostat calls for heat, the

burner will automatically light.

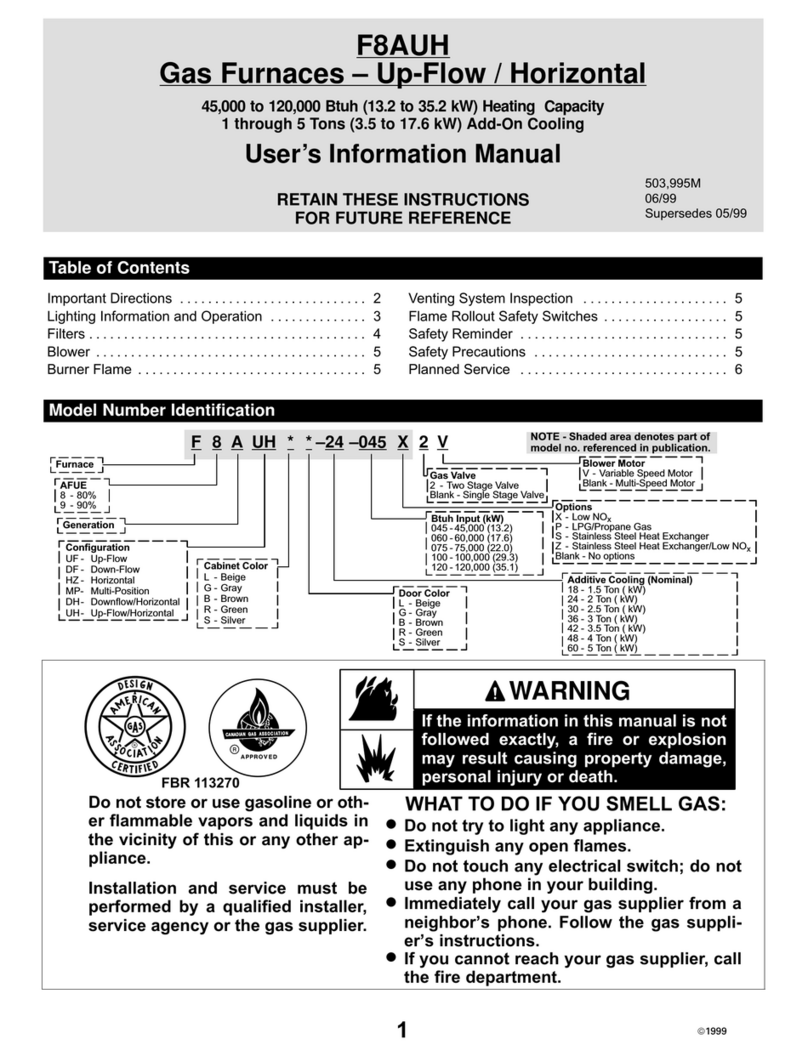

Gas Valve Operation (Figure 2 an 3)

1 - STOP! Read the safety information at the beginning

of this section.

2 - Set thermostat to owest setting. See figure 1.

THERMOSTATS

FIGURE 1

3 - Turn off a e ectrica power to app iance.

4 - This app iance Is equipped with an ignition device

which automatica y ights the burner. Do not try to

ight the burner by hand.

5 - Remove the contro access pane .