Page 1

504,919M

*P504919M*

04/04

*2P0404*

©2004 Lennox Industries Inc.

Dallas, Texas

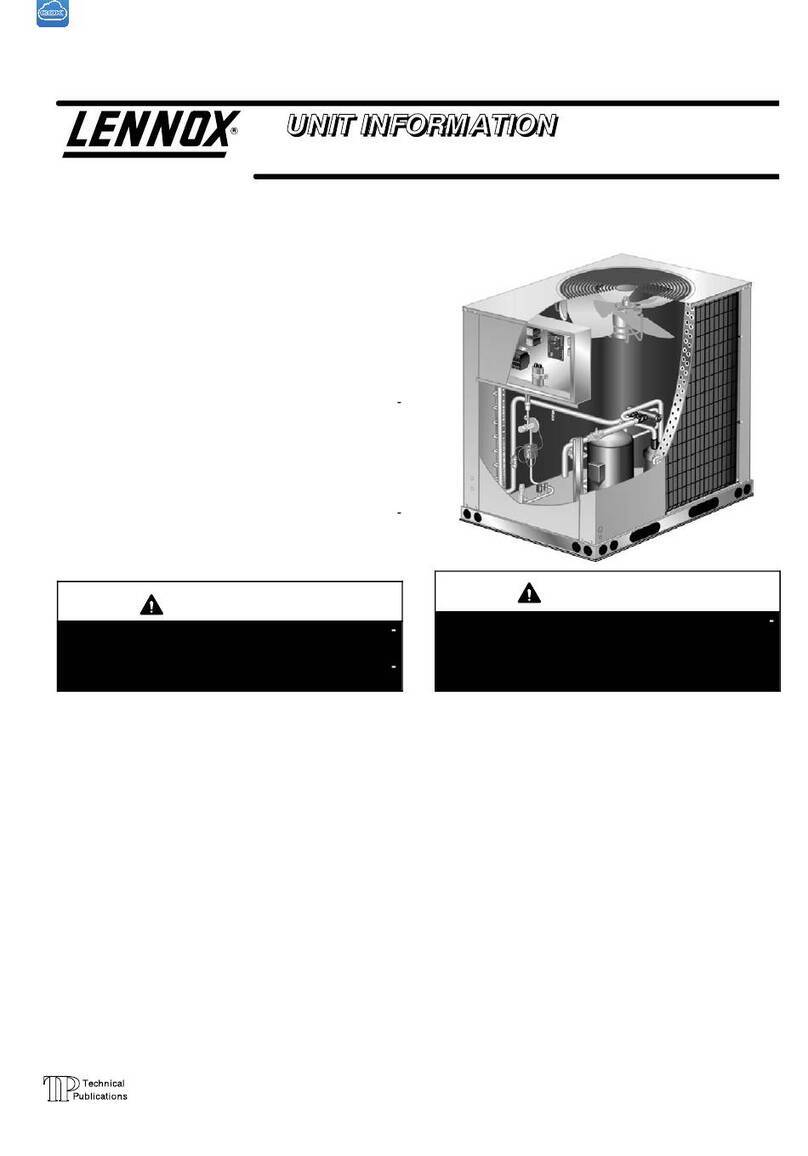

HSXA19 Outdoor Unit

Two−stage HSXA19 outdoor units use R410A which is an

ozone friendly HFC refrigerant. This unit must be installed

with a matching indoor coil and line set as outlined in the

Lennox Engineering Handbook. Dave Lennox Signature

Collection HSXA19 outdoor units are designed for use in ex-

pansion valve systems (TXV) only. They are not designed to

be used with other refrigerant flow control devices. The Len-

nox Engineering Handbook lists a TXV kit that must be or-

dered separately.

Shipping & Packing List

1 − Assembled HSXA19 outdoor unit

2 − Grommets (liquid and vapor line)

1 − Bushing (for low voltage wiring)

Check equipment for shipping damage. If you find any

damage, immediately contact the last carrier.

CAUTION

Danger of sharp metallic edges. Can cause injury.

Take care when servicing unit to avoid accidental

contact with sharp edges.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, person-

al injury or loss of life. Installation and service must

be performed by a qualified installer or service

agency.

IMPORTANT

This unit must be matched with an indoor coil as

specified in Lennox’ Engineering Handbook. Coils

previously charged with HCFC−22 must be flushed.

INSTALLATION

INSTRUCTIONS

HSXA19 SERIES UNITS

CONDENSING UNITS

504,919M

04/04

Supersedes 03/04

Table of Contents

HSXA19 Outdoor Unit 1. . . . . . . . . . . . . . . . . . . . . . . . . .

Shipping & Packing List 1. . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Dimensions 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Arrangement 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting The Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Piping 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Refrigerant Metering Device 11. . . . . . . . . . . . . . . . . . . .

Flushing Existing Line Set & Indoor Coil 11. . . . . . . . . .

Manifold Gauge Set 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Valves 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leak Testing 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Evacuation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start−Up 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Operation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 23. . . . . . . . . . . . . . . . . . . . . . . . . .

Homeowner Information 23. . . . . . . . . . . . . . . . . . . . . . . .

Check Points 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Retain These Instructions

For Future Reference

General Information

These instructions are intended as a general guide and do

not supersede local codes in any way. Consult authorities

who have jurisdiction before installation.

WARNING

This product and/or the indoor unit it is matched with

may contain fiberglass wool.

Disturbing the insulation during installation, mainte-

nance, or repair will expose you to fiberglass wool

dust. Breathing this may cause lung cancer. (Fiber-

glass wool is known to the State of California to

cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact your

supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379−9900

Litho U.S.A.