Contents

2

Contents

Contents...............................................................................................2

Important safety information.............................................................4

Intended use .........................................................................................4

Qualification of the staff ........................................................................4

Warning notices in these instructions ...................................................5

Further documents................................................................................5

Pay particular attention to .....................................................................5

General instructions..............................................................................5

Installation.............................................................................................6

Operation ..............................................................................................6

After switch-off and longer downtime....................................................6

Cleaning................................................................................................6

De-installation .......................................................................................6

Disposal ................................................................................................6

Scope of delivery ................................................................................7

Performance specifications...............................................................7

Application instructions.....................................................................8

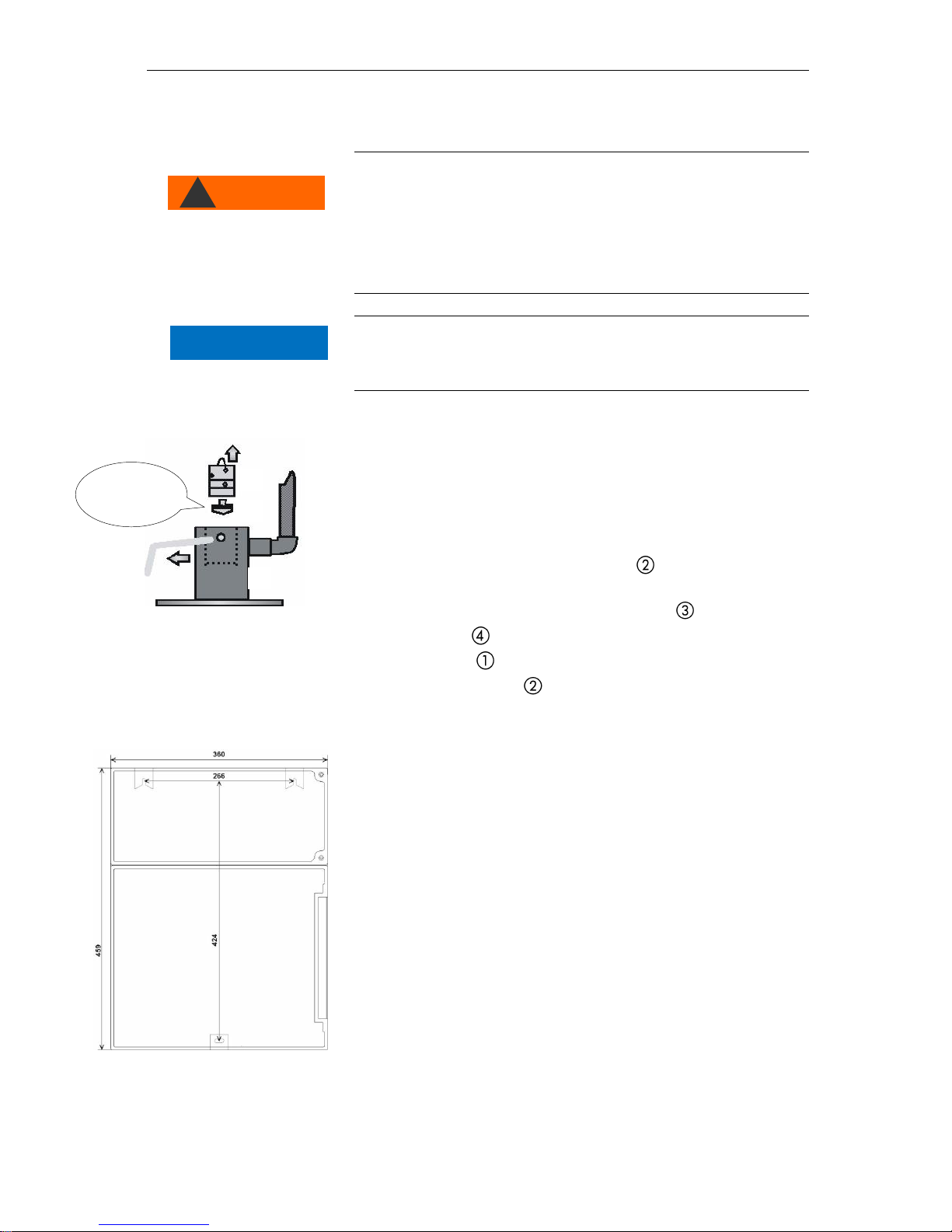

Installation...........................................................................................9

Operating Testomat 2000®Fe in the pressure range 0.3 to 1 bar........9

Installing Testomat 2000®Fe................................................................9

Connecting the water inlet and outlet .................................................10

Water inlet...........................................................................................10

Water outlet.........................................................................................10

Connecting the power supply and devices .........................................11

Block diagram Testomat 2000®Fe .....................................................11

Internal design Testomat 2000®Fe ....................................................12

Connecting the mains voltage.............................................................13

Connecting the plant components ......................................................14

Connecting the inputs and outputs .....................................................15

Commissioning.................................................................................16

Inserting reagent bottles .....................................................................16

Filling the reagent ...............................................................................16

Opening the water inlet.......................................................................16

Instrument settings and data input......................................................17

Functions of the operating and display elements.........................17

Switching Testomat 2000® Fe on/off...................................................17

Display functions.................................................................................18

Operating elements and function keys ...............................................19

Operating system................................................................................20

Password protection and basic program.......................................21

Entering basic program data...............................................................21

Selecting the operating mode.............................................................21

Selecting the displayed unit................................................................24

Entering further basic program data ..............................................25

Internal flushing...................................................................................25

External flushing .................................................................................25

Interval pause .....................................................................................26

Limit value monitoring.........................................................................26

Hysteresis ...........................................................................................27