General information

The controllers have an integrated PLC, field bus systems

and multi-axis control with a maximum of 11 controlled

axes (max 3 with ± 10 V and max. 8 with CAN bus). 64 axes

altogether can be controlled via the CAN bus (without

feedback). Additional inputs and outputs permit several

CAN REMOTE I/Os with up to 64 inputs or outputs per

node and up to 64 node addresses.

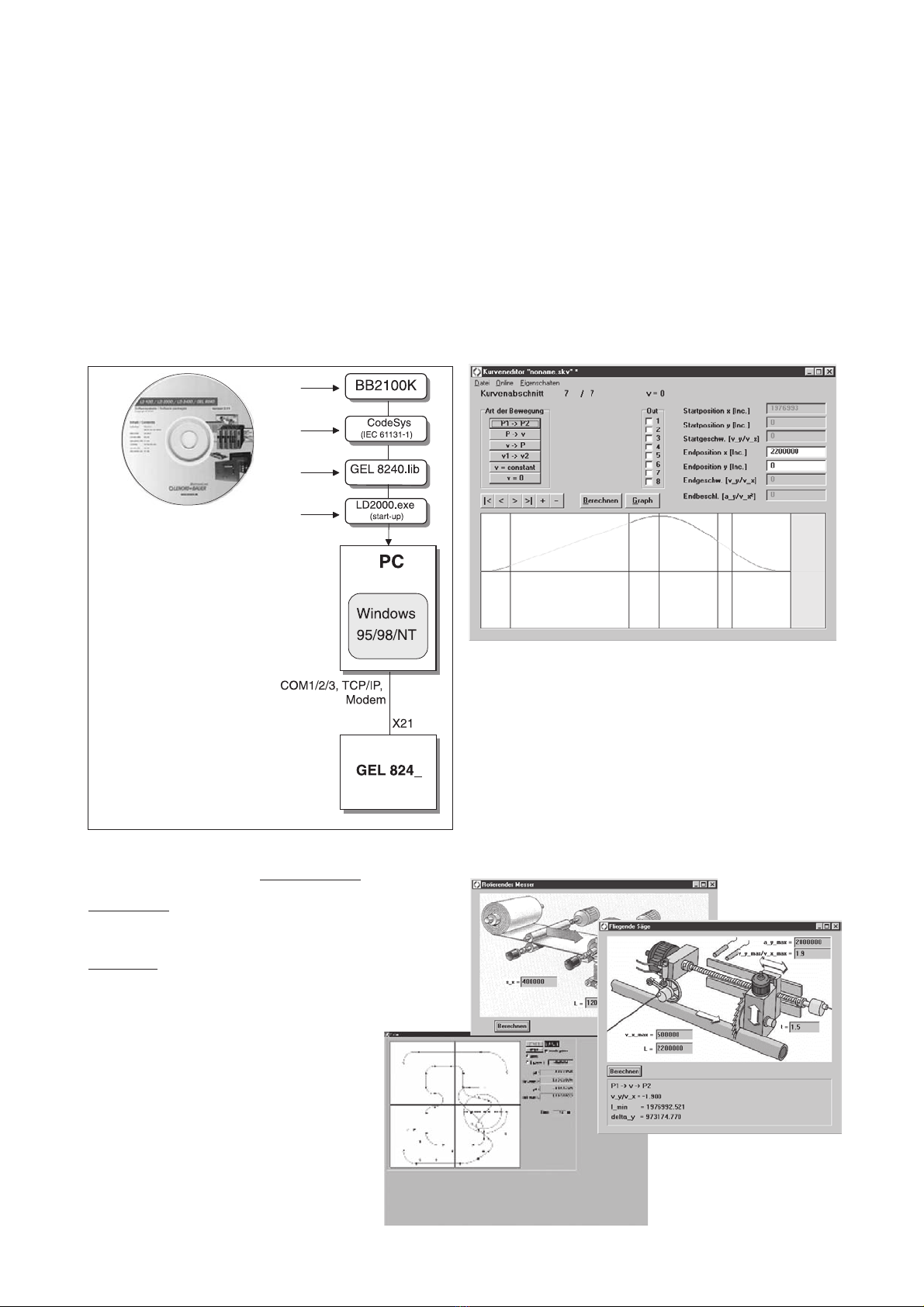

The standard CoDeSys programming environment runs in

parallel with the multi-axis control and offers full

transparency for all parameters. Parametrization of all 7

axes is effected by a PC tool and offers menu-guidance for

comfortable setting of the usual parameters.

The standard programming environment in acc. with IEC

61131-3 includes a library of ready-made and powerful

technology functions for terminal programming and

automatic motion control.

Up to four different communication channels are available

with one interface enabling all conventional field bus

systems (PROFIBUS-DP, DeviceNet,...) to be used.

The field bus modules can be retrofitted or replaced at any

time without the need to modify the PLC program.

The MotionPLCs differ only in design (see below).

Characteristics of the MotionPLCs

GEL 824x

•- RAM: 1 MBytes altogether

- NVRAM: 8 kByte altogether

- Flash: 1 MByte altogether

- free memory space for PLC applications: 256 kBytes

•2 CAN bus interfaces

(servoconverter, CAN REMOTE I/O module)

•2 asynchronous interfaces

(one optionally RS 232 or RS 485 and RS 422)

•high noise immunity due to electrically isolated digital

and analog inputs and outputs

•3 encoder inputs (SSI, incremental, 5 V / 24 V)

•short projecting times due to ready-made functional

blocks and pre-configured inputs and outputs

Multi-function control

MotionPLC GEL 8240/8241

GEL 8245/8246

PLC and cam-plate functionality

Technical information version 04.05

Internet: http://www.lenord.de Tel.: +49 (0)208 9963-0 Lenord, Bauer & Co. GmbH

E-Mail: info@lenord.de Fax: +49 (0)208 676292 Dohlenstrasse 32

46145 Oberhausen, Germany

▲GEL 8240/8241

▲GEL 8245/8246

0428LEG1428LEG5428LEG6428LEG

lenapyekdnaDCLseyseyonon

stupnilatigiD22032203

stuptuolatigiD51515151

stupnieugolanA1313

stupni001TP0404

stuptuoeugolanA 3333

Device variants