Description

2DS22-6113 / (2017-08)

System concept

The positioning drives belong to the product group

PowerDRIVE-Positioning and are a component of the

PowerDRIVE system.

Each positioning drive in the GEL 6113 series is an

intelligent adjustment unit for pushing onto the end of a

shaft or for attachment to a shaft or spindle.

The positioning drive can be integrated directly into a plant

control system via the communication interfaces

integrated.

PowerDRIVE-System

The PowerDRIVE-System is suitable for the efficient

integration of several positioning drives in a machine or

plant. The system consists of the following components:

PowerDRIVE-Positioning:

Positioning drive for fully automatic format adjustment

PowerDRIVE-Motion:

Positioning drive for cyclic operation

PowerDRIVE-Box:

Decentral control unit for up to 5 drives

PowerDRIVE-Connect:

Single cable concept (hybrid cable suitable for drag

chain)

PowerDRIVE-Lib:

Ready-made function blocks for integration in the

machine control system

PowerDRIVE-Support Tool:

Software for advanced commissioning and configuration

The usage of PowerDRIVE-Box and PowerDRIVE-

Connect significantly reduces the cabling effort for the

positioning drives. Instead of the usual two separate

cables for internal bus communication and a third cable to

supply power to the positioning drives, only ONE hybrid

cable suitable for use in drag chains is connected. In the

maximum configuration with 5 positioning drives

connected, the number of cables typically reduces from 15

to 5 due to PowerDRIVE-Connect. With the aid of the

PowerDRIVE-Box the overall system offers a high degree

of flexibility during integration, as it supports all common

communication interfaces.

Construction

The PowerDRIVE-Positioning GEL 6113 is operated with a

supply voltage of 24 V DC and supports fieldbus profiles

(CANopen (CiA 402); PROFIBUS-DP (V0/V1)) and

Industrial Ethernet protocols (Sercos III; POWERLINK;

PROFINET IO / RT; EtherCAT; EtherNet/IP).

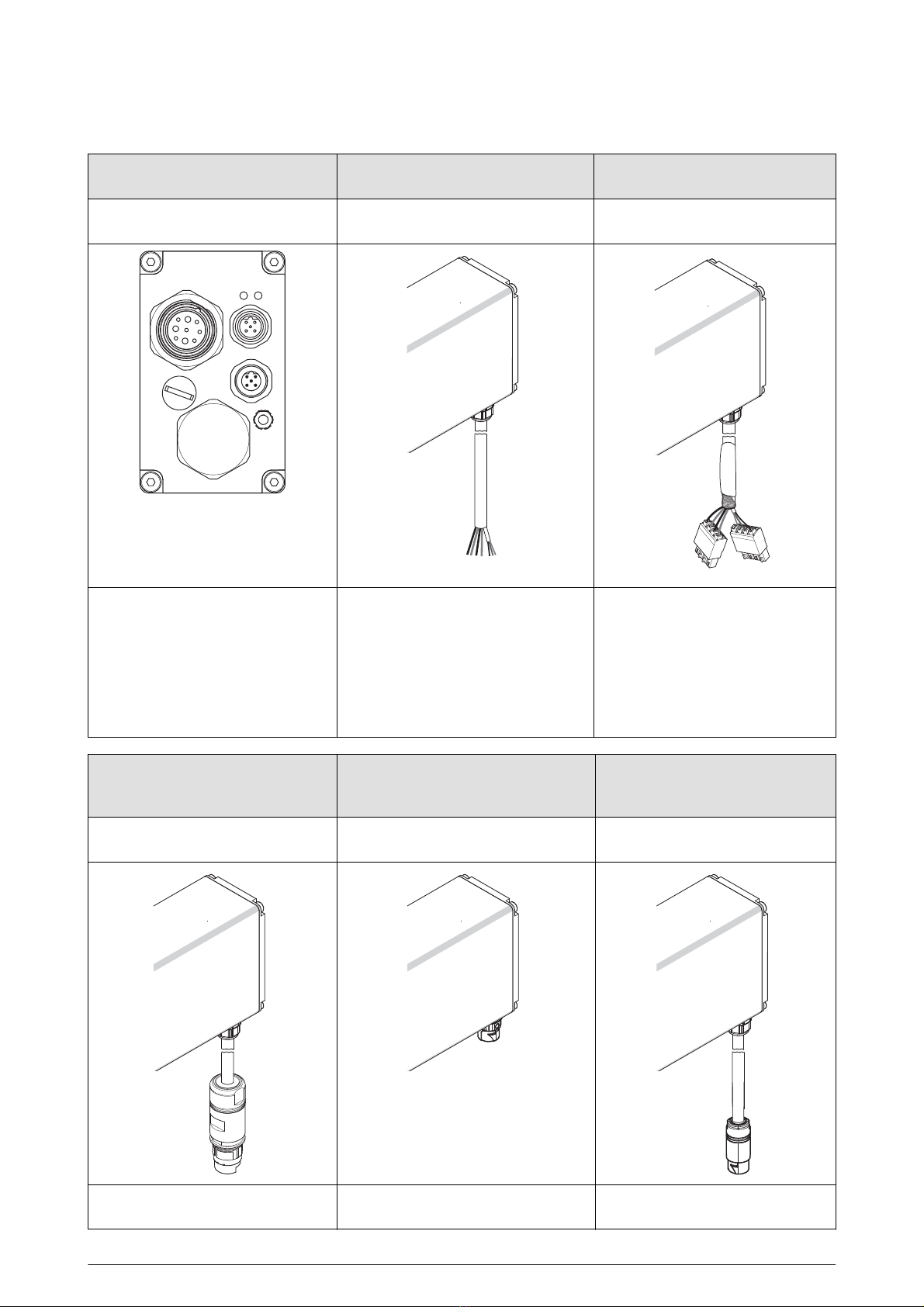

PowerDRIVE-Connect is available with either a plug

connection or hybrid cable.

The rigid housing made of anodised aluminium is

particularly robust and achieves the degree of protection

IP 67 due to the Viton shaft sealing ring.

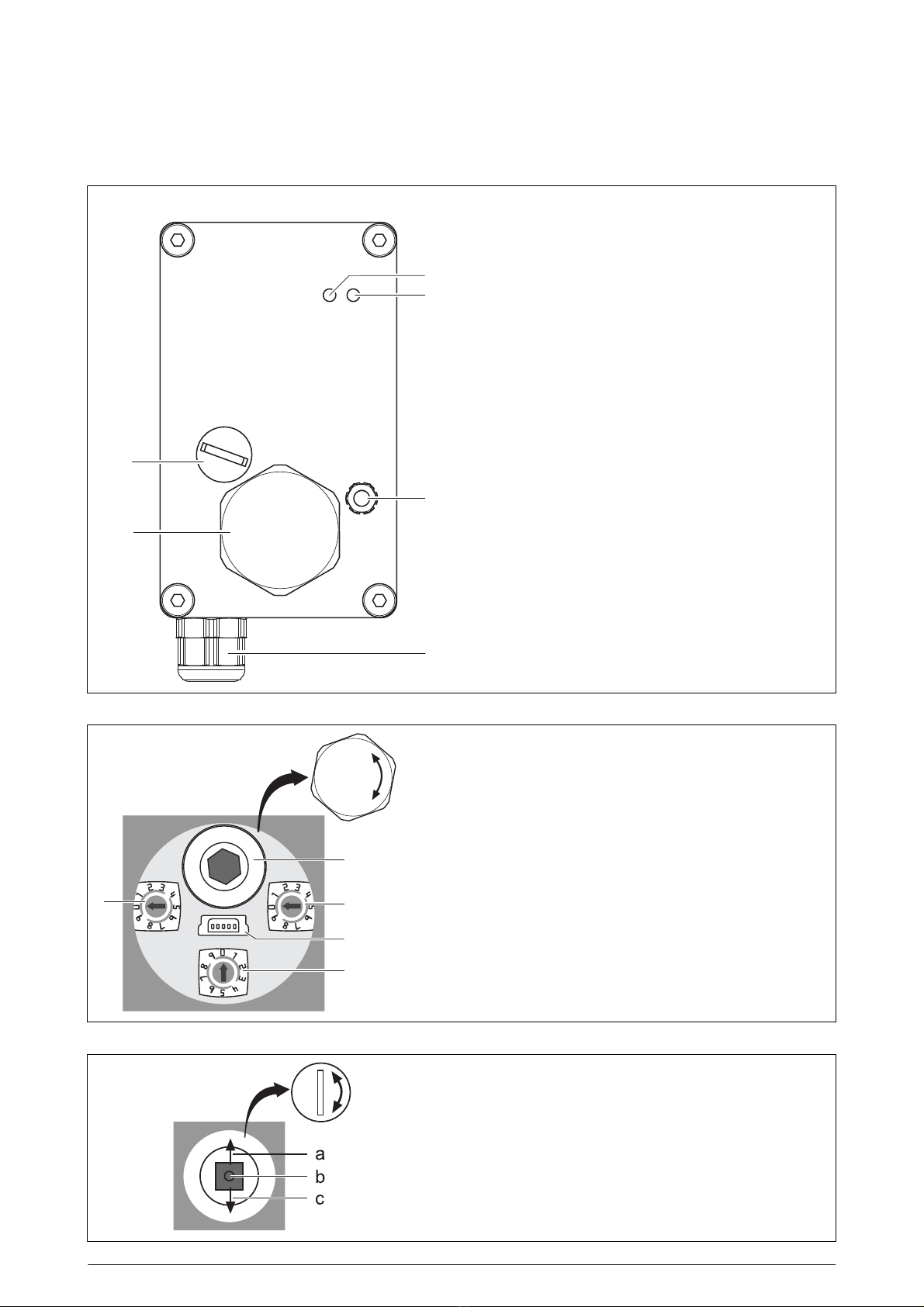

The positioning drive is equipped with mechanical manual

adjustment so that the positioning drive can be actuated if

there is a fault, e.g. a power failure.

A USB service connector is accessible on the rear of the

device for service purposes.

The device variants with integrated fieldbus (CANopen

(CiA 402); PROFIBUS-DP (V0/V1)) have rotary selection

switches for setting the device ID and baud rate, as well as

an onboard joystick. The positioning drive can be operated

in the set-up mode using the joystick without prior PLC

programming. All elements are accessible on the rear of

the device.

Integrated absolute rotary encoder

A magnetic-absolute multiturn rotary encoder makes

reference search routines after a power failure or

emergency stop unnecessary. Due to the batteryless

encoder, the positioning drive detects its position after

power on and is immediately ready for use.

In the switched off state the drive shaft can be moved by

±57 turns without loss of the absolute position.

The absolute rotary encoder withstands high shock/

vibration loads.