Lenze 13466187 EDBTL03 v8 EN, DE, FR, IT, ES 3

Safety information

1 Safety information

General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be

live, moving and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or

operation creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance

mustbecarriedoutbyqualied,skilledpersonnel(IEC364andCENELECHD384 or DIN

VDE 0100 and IEC report 664 or DIN VDE0110 and national regulations for the prevention of

accidents must be observed).

Accordingtothisbasicsafetyinformation,qualiedskilledpersonnelarepersonswhoarefamiliar

with the installation, assembly, commissioning, and operation of the product and who have the

qualicationsnecessaryfortheiroccupation.

Application as directed

Drive controllers are components which are designed for installation in electrical systems or

machinery. They are not to be used as appliances. They are intended exclusively for professional

and commercial purposes according to EN 61000-3-2. The documentation includes information

on compliance with the EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation

as directed) is prohibited until it is proven that the machine complies with the regulations of the

EC Directive 2006/42/EC (Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is compliance

with the EMC Directive (2004/108/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 2006/95/EC. The

harmonised standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

Note: The availability of controllers is restricted according to EN 61800-3.These products can

cause radio interference in residential areas. In this case, special measures can be necessary.

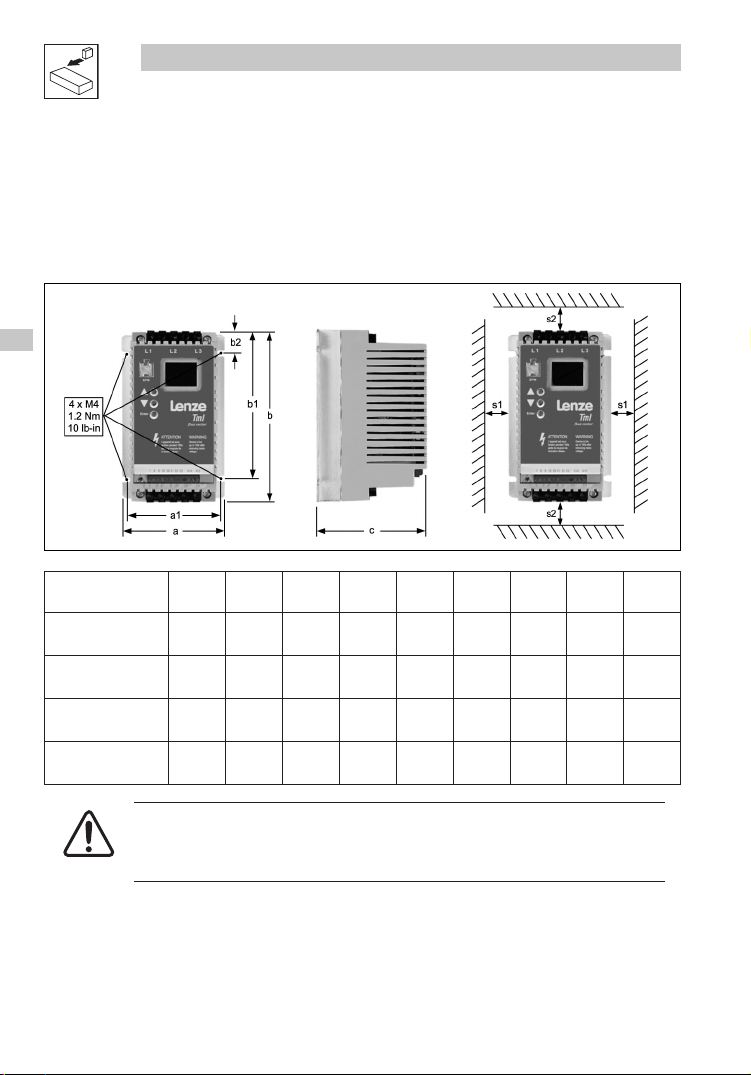

Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components

and do not change any insulation distances during transport or handling. Do not touch any

electronic components and contacts.

Controllers contain electrostatically sensitive components, which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this might

endanger your health!

Electrical connection

When working on live drive controllers, applicable national regulations for the prevention of

accidents (e.g. VBG 4) must be observed.

The electrical installation must be carried out according to the appropriate regulations (e.g.

cable cross-sections, fuses, PE connection). Additional information can be obtained from the

documentation.

The documentation contains informa3tion about installation in compliance with EMC (shielding,

grounding,ltersandcables).ThesenotesmustalsobeobservedforCE-markedcontrollers.

The manufacturer of the system or machine is responsible for compliance with the required limit

values demanded by EMC legislation.