ML electric guitar DIY Kit

3

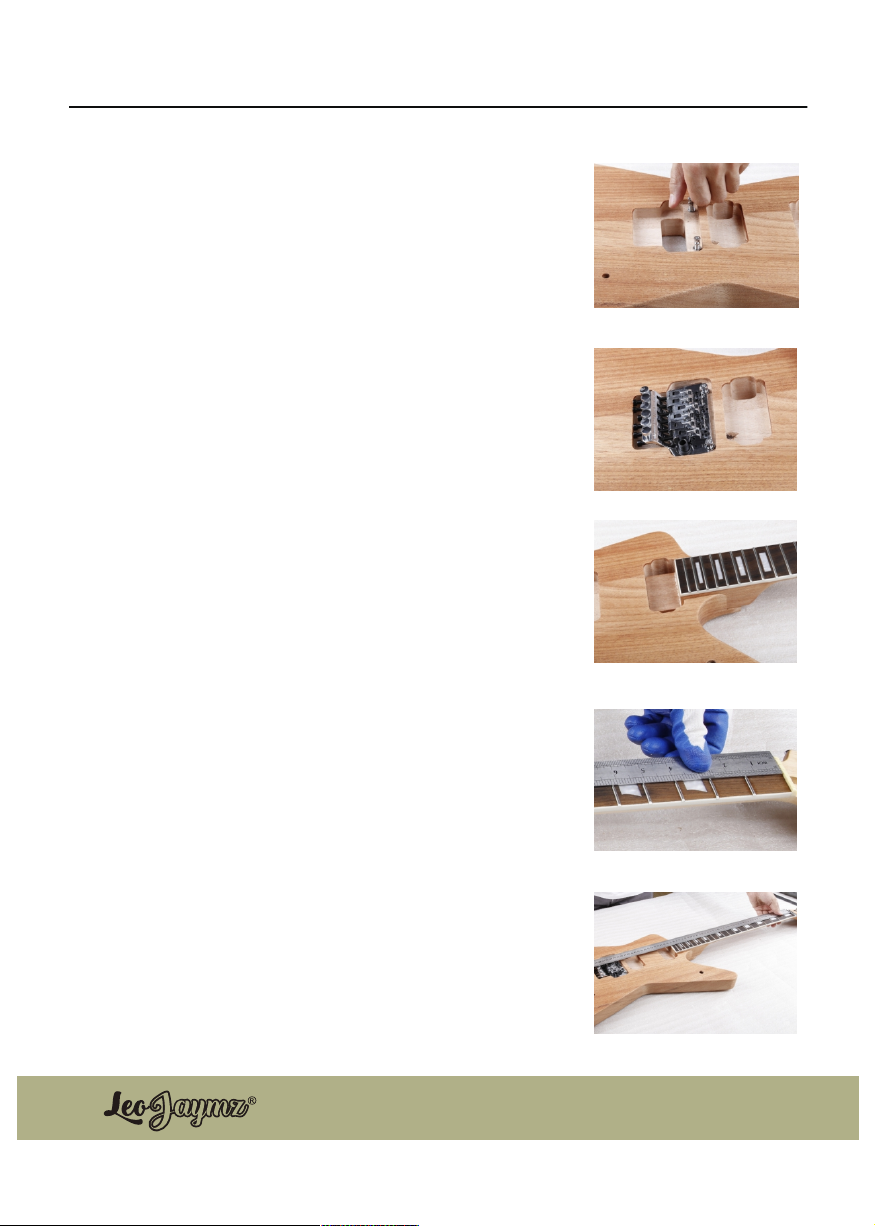

3Assembling

3 Assembling

3.1 Sand the body and neck

3.1.2 Fillup the grain

Thebody of the BCguitar is madeof Solid mahogan,

and theneck is made of solid maple. Open grained woods

need to be filled before finishing in order to achieve a flat

surface.

WesuggestusingourNeutral Color Tonegrainfiller

following the instructions on the label. Three applications

are recommended to get a nice flat surface to build finish

coats over.The grainfiller can also be used to fill any gaps,

chips,or other imperfections in the wood.

Asa general rule, you should fillup the grainuseNeutral

Color Tone grainfiller until you can't seethe poresofthe

wood with the nakedeyes. Then we can start for the

precess below.

3.1.3 Paint your favorite color

Use a damp cloth for dip with your favorite color and

wipe on the body and neck as you like. Not only one

time may can not reach the exactly what you espected,

so sand with 320-grit and wipe again and again until

got your lovely color. Here we take the natural color as

example.

3.1.1 Sand the body and neck

It is a very thin maple veneer glue on the top of the

body. Using 320 or higher grade-gritsandpaper on a

foam sanding block, lightly sand the entire body working

only in the direction ofthe grain.

Aftera complete sanding,wipe the body with adamp

cloth to raise the grain,to reveal fibers that need more

sanding. Let thedampnessdry,then sandthe raisedgrain

againusing 320 or higher-gritsandpaper. Sand the

neckwith 220-grit followedby320-grit.