7

INSTALLATION AND MAINTENANCE

Pjn

Servo gearboxes

STORAGE - INSTALLATION RECOMMENDATIONS - LUBRICATION

LEROY-SOMER

3832 - 03.2005 / a

1 - STORAGE

Pjn servo gearboxes can be stored horizontally in a dry place

at a temperature between 0° and 30°C in their original

packaging (for a maximum of one year). (The threads and the

area below the screw heads of the locking clamps are

lubricated with molybdenum disulphide).

The service life of servo gearboxes increasingly depends on

how well they are maintained.

2 - INSTALLATION

RECOMMENDATIONS

Servo gearbox :

For the installation of Pjn servo gearbox, follow the

"Recommendations" chapter in the general manual (ref. 2557).

Servo motor :

For connection of the complete drive system (with brake),

follow the instructions of corresponding maintenance

delivered with the goods in the parcel.

3 - LUBRICATION

The Pjn servo gearbox is supplied as standard lubricated with

an oil with a viscosity of 150 mm

2

/S that is heavy pressure

wear-resistant against the risks of pitting, spalling and

abrasion with a very high natural viscosity index and complete

stability at shearing. (Klüber ref. GH6-150).

You must use an oil of the recommended type.

Please observe the oil quantities specified in the

table opposite.

(Magnetic plugs make filling,

pressure relieving and draining easier, and retain any metallic

particles).

POLYGLYCOL LUBRICANTS CANNOT BE MIXED WITH

MINERAL OR SYNTHETIC LUBRICANTS OF A

DIFFERENT TYPE.

3.1 - Maintenance, draining

It is advisable to carry out initial draining after between 100

and 500 operating hours in order to remove the initial residue

from operation. Subsequent draining should preferably be

carried out every 10,000 hours. For harsh applications,

please consult Leroy-Somer.

Observe the recommended

draining intervals and oil quantities.

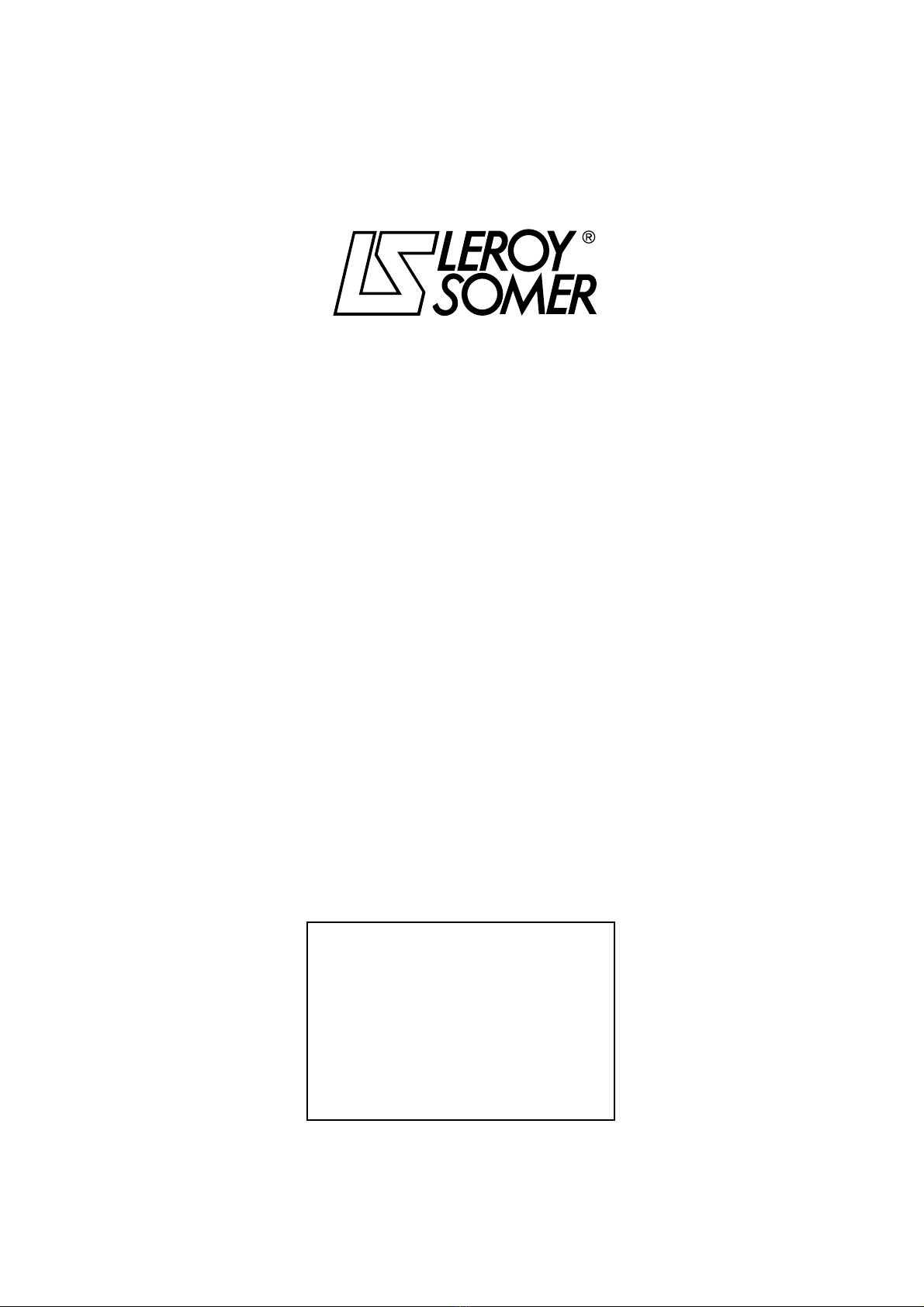

3.2 - Plugs position

a - Servo gearboxes have an upper plug for

refilling

and a

lower plug for

draining

. The position of these plugs depends

on the operating position of the servo gearbox, which must be

specified at the time of ordering

.

b - For continuous operation at rated speed, the optional

breather plug must be installed.

After installing the servo gearbox on site, insert the breather

plug in the place of one of the standard plugs and observe the

orientation of the vent hole.

3.3 - Oil capacity (cm

3

)

For all other operating positions, follow the quantities

specified in column V3.

Lubricants:

Operating position

1. Indifferent orientation

of the vent hole

2. Position of the plug for

servo gearboxes ratio 3 to

10

3. Orientation of the vent hole at the top

R: Fill plug

V: Drain plug

Type

Operating position

Pjn B5, B52, B53, B54 V3 V1

0801

30 30 50

0802

50 50 70

0803

70 70 100

1101

90 90 100

1102

130 130 220

1103

190 190 340

1401

170 170 190

1402

250 315 390

1403

330 400 590

1801

250 250 285

1802

400 500 685

1803

550 800 1085

1901

250 250 285

1902

400 500 685

1903

550 800 1085

2401

600 600 600

2402

900 1200 1550

2403

1200 2000 2400

Brands Reference Viscosity

KLÜBER

GH 6-150 150 mm

2

/S

MOBIL

Glygoyle-22 163 mm

2

/S

MOTUL

Berusynth EP 150 158 mm

2

/S

SHELL

Tivela WA 158 mm

2

/S

Approved lubricant

2

1

R

V

R

R

V

V

3

3

B5, B52, B53, B54 V3 V1

en