Shanghai Jianghuai Environmental Equipment Co.,LTD

Catalogue

Precautions ......................................................................................................................................... 4

Machine operating instructions ..........................................................................................................6

Machine Installation ........................................................................................................................... 7

Open packaging machines ..................................................................................................................7

Install battery ......................................................................................................................................8

Working methods of Machine ............................................................................................................8

Information of Brush and scouring pad ............................................................................................. 9

Machine installation ........................................................................................................................... 9

Brush / scouring pad Installation ......................................................................................................10

Machine operation ........................................................................................................................... 10

Preflight Checks .................................................................................................................................10

Operating the machine .....................................................................................................................11

During operation of the machine ..................................................................................................... 11

Battery charge gauge ........................................................................................................................11

Drain Tank ......................................................................................................................................... 11

Battery charge ...................................................................................................................................12

Machine maintenance ...................................................................................................................... 13

Daily maintenance ............................................................................................................................ 13

Monthly maintenance ...................................................................................................................... 14

Quarterly Maintenance .................................................................................................................... 15

Handling Machine .............................................................................................................................15

Storage Machine ............................................................................................................................... 15

Operational steps........................................................................................................................... 16

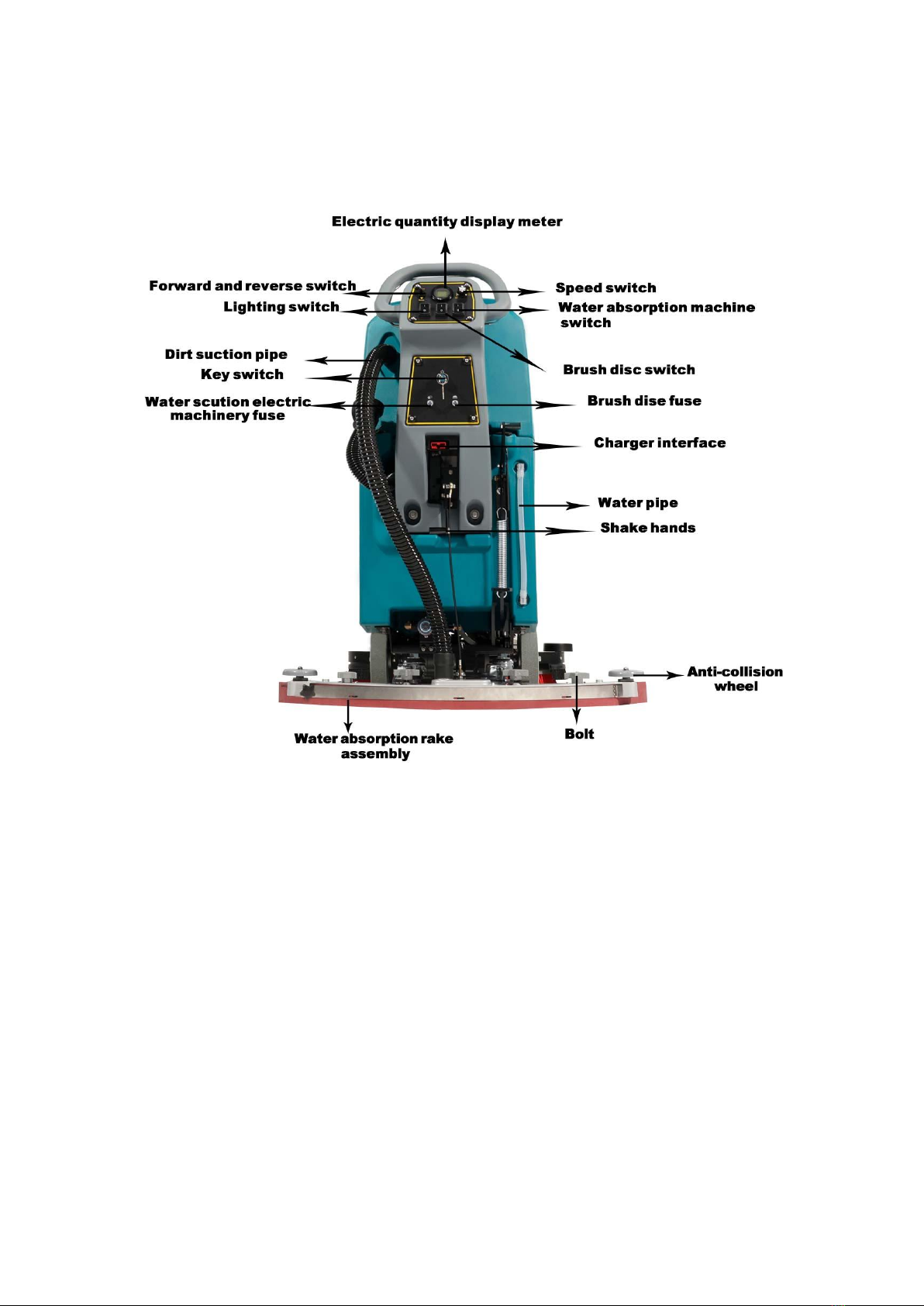

Machine Components.....................................................................................................................17

Sewage tank system........................................................................................................................18

Trouble excluding ..............................................................................................................................25

Machine Dimensions.................................................................................................................... 26