Contents

Precautions······························ ··4

Machine operation indication························6

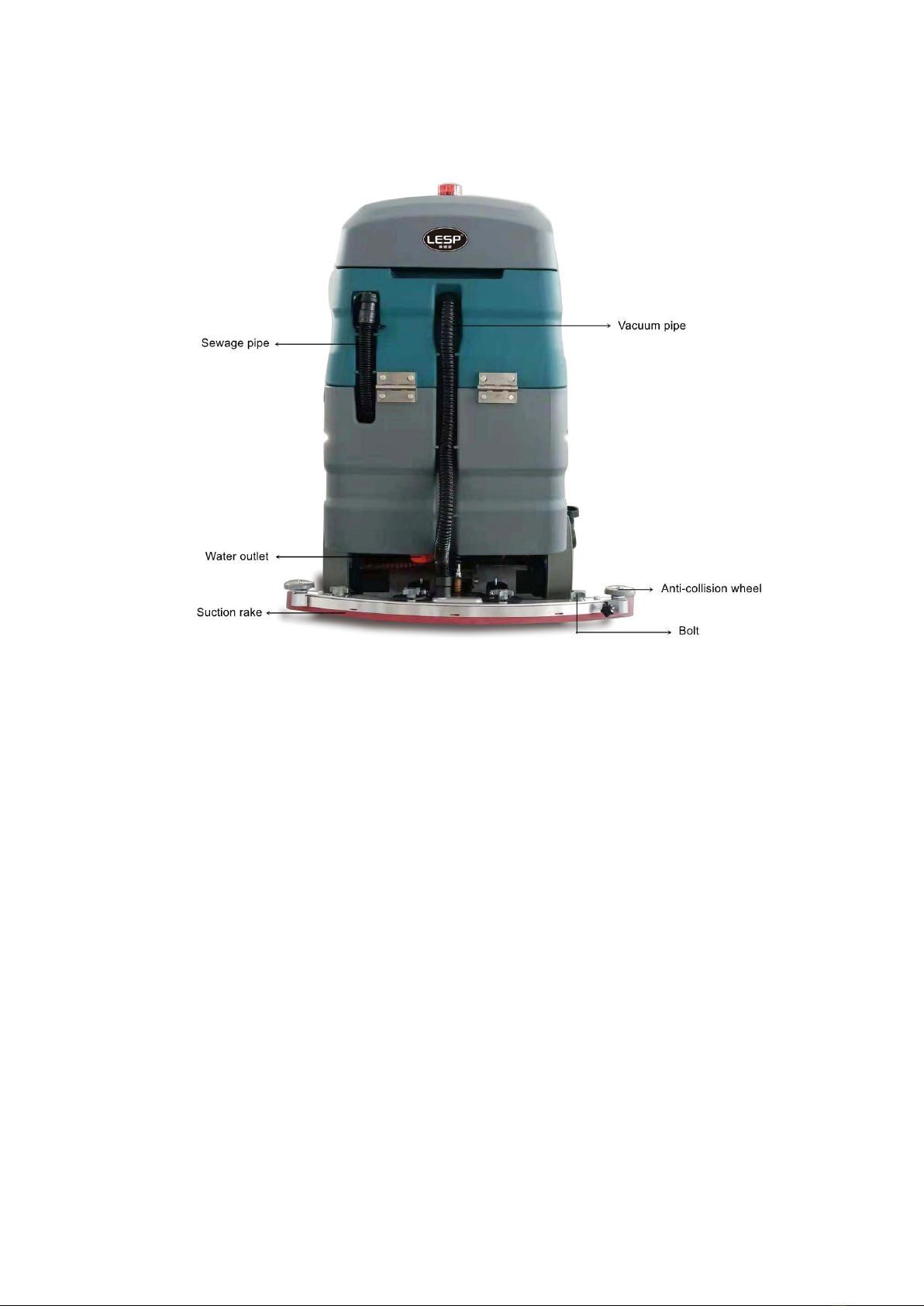

Receiver··································7

Unpacking the machine···························7

Installing the battery···························8

Machine cleaning method··························8

Brush and scouring pad information·····················9

Machine installation······················ ·····9

Attaching squeegee assembly ························9

Installation brush / scouring pad·····················9

Machine operation·····························9

Check before operation··························10

Operating machine·····························10

During the operation of the machine····················10

Battery Electricity Meter·························11

Water tank drainage····························11

Emission of sewage tanks··························11

Discharged water tanks···························11

Battery Charging······························11

Machine Maintenance····························12

Daily maintenance·······························12

Monthly maintenance·····························12

Quarterly maintenance····························13

Transportation machine····························13

Storage Machine·······························13

Troubleshooting································14

Machine parameters·····························15