Leuze electronic S300 3

TNT 35/7-24V

1 About this document............................................................................................ 5

1.1 Other applicable documents ................................................................................................5

1.2 Used symbols and signal words ..........................................................................................6

2 Safety................................................................................................................... 7

2.1 Approved purpose and foreseeable improper operation......................................................8

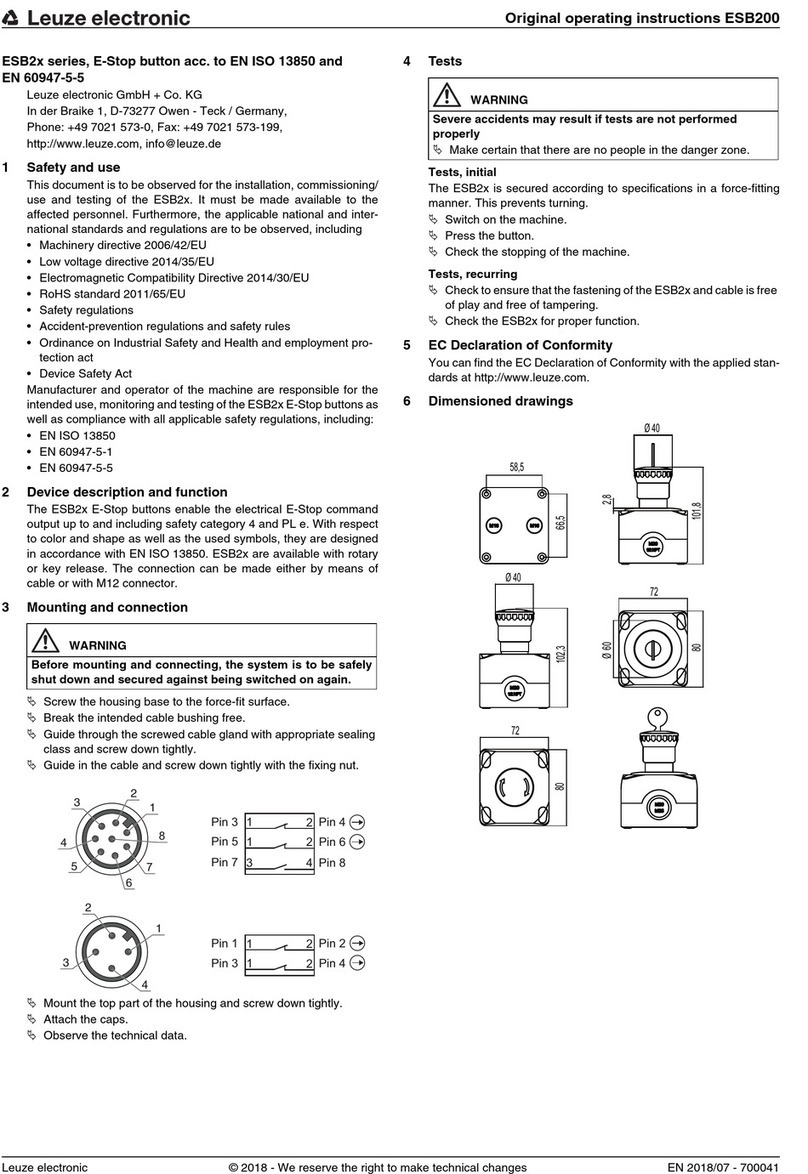

2.1.1 Proper use.....................................................................................................................................8

2.1.2 Foreseeable misuse ....................................................................................................................10

2.2 Competent personnel.........................................................................................................10

2.3 Responsibility for safety.....................................................................................................10

2.4 Exemption of liability ..........................................................................................................11

3 Device description ............................................................................................. 12

4 Functions ........................................................................................................... 17

5 Applications ....................................................................................................... 18

6 Mounting............................................................................................................ 19

6.1 Adjusting the switching and approach direction.................................................................19

6.2 Mounting the Safety Position Switch..................................................................................22

7 Electrical connection.......................................................................................... 26

7.1 Connecting the contact block.............................................................................................26

7.2 Contact block characteristics .............................................................................................27

8 Setting the device into service........................................................................... 29

9 Testing............................................................................................................... 30

9.1 To be performed prior to the initial start-up by competent personnel.................................30

9.2 To be performed periodically by competent personnel......................................................30

9.3 To be performed daily by the operating personnel ............................................................31

10 Cleaning............................................................................................................. 32

11 Disposing........................................................................................................... 33

12 Service and support........................................................................................... 34

13 Accessories ....................................................................................................... 35

13.1 Accessory dimensional drawings.......................................................................................36

14 Technical data ................................................................................................... 37