WARNING: TO AVOID FIRE, SHOCK, OR DEATH; TURN

OFF POWER at circuit breaker or fuse and test that power is

off before wiring!

Preparing and connecting wires:

Make sure the wires from the wall box are straight (cut if

necessary). Remove insulation from each wall box wire and

Sensor Power Base as shown:

Occupancy Sensor Power Base

Cat. No. OPB15

15A @ 120V, 60Hz – Fluorescent/Incandescent

15A @ 277V, 60Hz – Fluorescent

3/4 hp @ 120V, 60Hz

2 hp @ 277V, 60Hz

For use with OSCxx Occupancy Sensors

INSTALLATION INSTRUCTIONS

Mount power base in desired electrical box

application:

A. To mount inside 4" octagon 2.125" deep ceiling

electrical box, refer to Figure 1. Wire per Step 2.

• Dress line voltage wires to provide enough clearance in electrical

box when device is installed.

• Partially thread the two #8-32 screws provided into mounting

holes of the electrical box.

• Align the power base body so that it fits between the mounting

holes of the electrical box and insert over mounting screws.

• Turn counter clockwise until it reaches the stops.

• Tighten mounting screws firmly.

Tools needed to install your Sensor:

Slotted/Phillips Screwdriver

Pliers

Cutters

Parts Included List:

Sensor Base (1)

#8-32 x 3/4" Screw (2)

#6-32 x 13/16" Screw (2)

FEATURES

• Adapts OSCxx Sensors to line-voltage

• 24VDC Output

• Mounts inside a 2.125" deep octagon or 4" square

Electrical Box (w/mud ring)

DESCRIPTION

The OPB15 adapts Leviton low-voltage ceiling occupancy sensors

to operate on line-voltage electrical systems. Designed to control

up to 15 amps of lighting load from a single occupancy sensor. The

Power Base contains a power supply and a load switching relay. The

power supply provides Class II low-voltage power for OSCxx Series

Occupancy Sensors. The relay in the Power Base is controlled by the

occupancy sensors connected via the control input of the two-part

terminal connector. The Power Base includes zero cross switching

circuitry to minimize inrush current associated with electronic ballasts.

This reduces wear and tear on the relay contacts making the power

pack last longer.

Application Notes:

OPB15 works well where installation of a low-voltage wiring typical

with traditional power packs and sensors is difficult, inconvenient or

costly. It is ideal for existing buildings where access to wiring is limited

or for new construction with line-voltage circuiting only.

LOW-VOLTAGE CURRENT CAPACITY

OPB15 is designed for a single occupancy sensor with a maximum

current capacity of 40mA.

INSTALLING YOUR OCCUPANCY SENSOR POWER

BASE

NOTE: Use check boxes when Steps are completed.

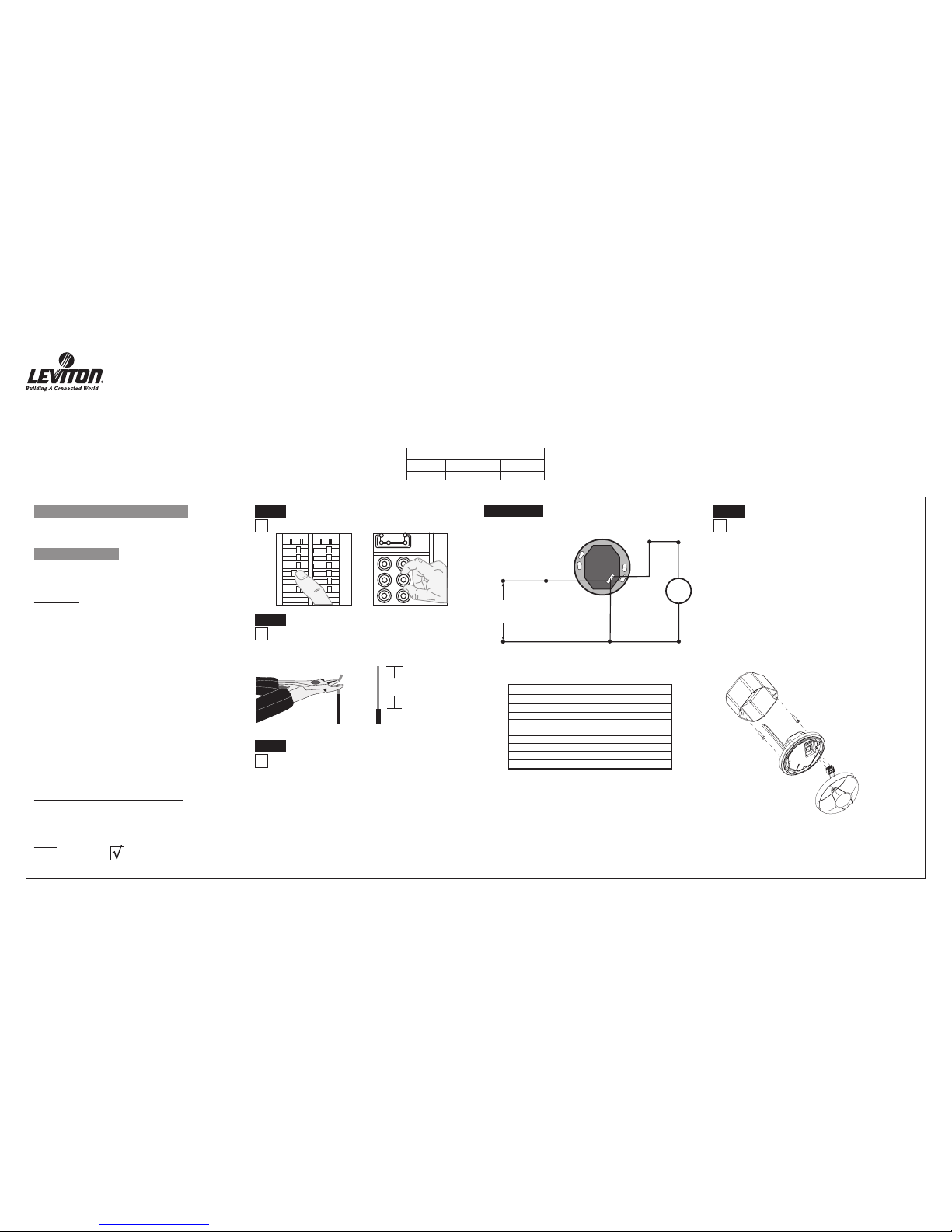

Step 1

WARNINGS AND CAUTIONS:

• To be installed and/or used in accordance with appropriate electrical codes and regulations.

• If you are unsure about any part of these instructions, consult a qualified electrician.

• Sensors must be mounted on a vibration free surface.

5/8"

(1.6 cm)

Strip Gage (measure bare

wire here)

Step 3

Step 2

Figure 1

Ceiling Installation in a 4" Octagon 2.125" Electrical Box

DI-000-OPB15-00A-X3

CATALOG ITEMS

Catalog No.

OPB15-0DW

Power Input

120-277VAC, 60Hz

Power Output

24VDC, 40mA

• Input voltage tolerance 10%

• Output voltage tolerance 15%, Output voltage listed at nominal.

Wiring your Sensor Power Base (Line Voltage):

NOTE: This application is based on the wall box being

pre-installed.

Connect wires per WIRING DIAGRAM as follows: Twist

strands of each lead tightly together and, with circuit

conductors, push firmly into appropriate wire connector.

Screw connectors on clockwise making sure no bare

conductors show below the wire connectors.

Step 4

All wires rated at 105° C. 600V insulation.

Class II wires are Teflon coated.

Signal Name Color Gauge

Line Voltage Wires

Line 120/277V Black 14AWG

Neutral White 14AWG

Load Blue 14AWG

Class II Two-Part Terminal

Common Black 22AWG

Power (+24VDC) Red 22AWG

Control (Occupancy Sensor) Blue or Gray 22AWG

WIRE DESIGNATIONS

Step 3 cont’d

WARNINGS AND CAUTIONS:

• All sensors must be mounted at least 6 feet away from air vents.

• Disconnect power when servicing fixture or changing lamps.

• Use this device only with copper or copper clad wire. With aluminum wire use

only devices marked CO/ALR or CU/AL.

Cut

(if necessary)