4

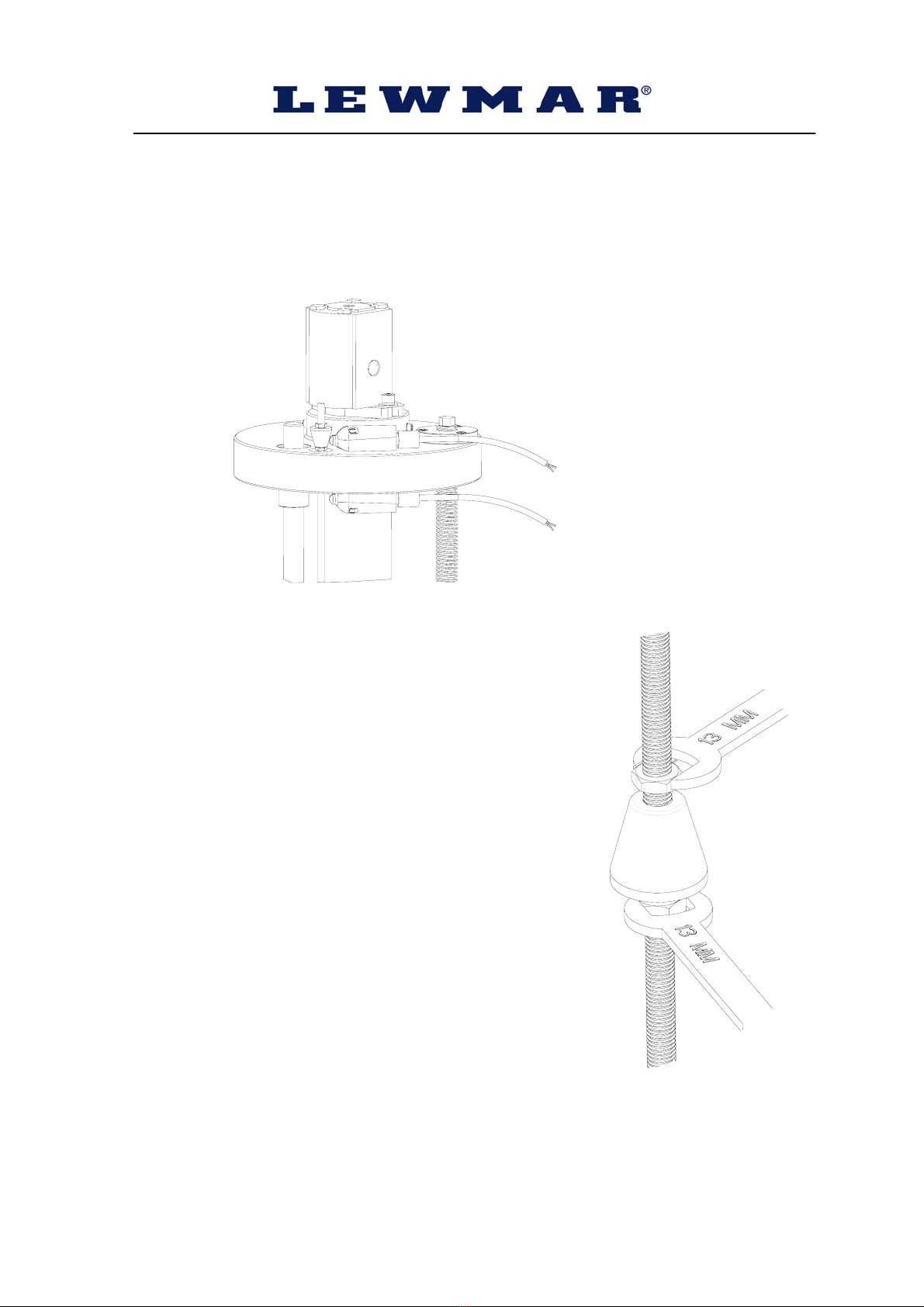

2.1.2 Lifting the unit

The Thruster is heavy so when lifting the Thruster unit from its packing case,

ensure that adequate lifting strops are used. The Thruster should not be lifted

by its lead screw assembly or propeller shroud. Extra caution should be used

to avoid damaging these parts, the micro switches and control box. When

moving the Thruster, ensure that the seating surfaces of the main housing are

protected against potential damage. The control box is secured to the

Thruster for protection during transit. A picture is included in the transport box

showing advised lifting method.

2.1.3 Fitting into the hull

The thruster requires a watertight compartment to be constructed within the

hull to house the shroud assembly, with an opening in the bottom of the hull

for the shroud to be lowered through.

The top of this watertight compartment is to act as the mounting seat for the

thruster base plate. This watertight compartment must be designed to take the

weight of the thruster, the transfer of thrust to the hull and any additional

forces created while the vessel is in motion. It is recommended that this is

carried out by a qualified navel architect.

When planning the Hull piece cut-out and watertight box, it is important that

the box gives adequate all-round clearance for the shroud of approx 5-10mm

(3/16-3/8”). Once the Thruster seating support has been fabricated and a

suitable hole has been cut in the hull, the Thruster can be installed.

Seat the unit down on a thin gasket of closed cell neoprene or a suitable

sealing compound. The base plate is pre-drilled with 8.5mm holes (250 VRTT)

or 10.5 holes (300 VRTT) see unit diagrams. It is recommended that stainless

steel bolts of property class 70 are used with nuts, plain washers and locking

washers. If fitting into an aluminium hull the base plate may be welded to the

watertight box. The thruster base plate is corrosion resistant 5083-T6.

The VRTT Thruster is supplied in the retracted position for ease of

transportation. The Thruster will need to be lowered once located, to have the

hull faring fitted. To lower the Thruster, either energise the raise/lower motor

or by using the mechanical lead screw (refer to Manual Raise/Lower section

for details).

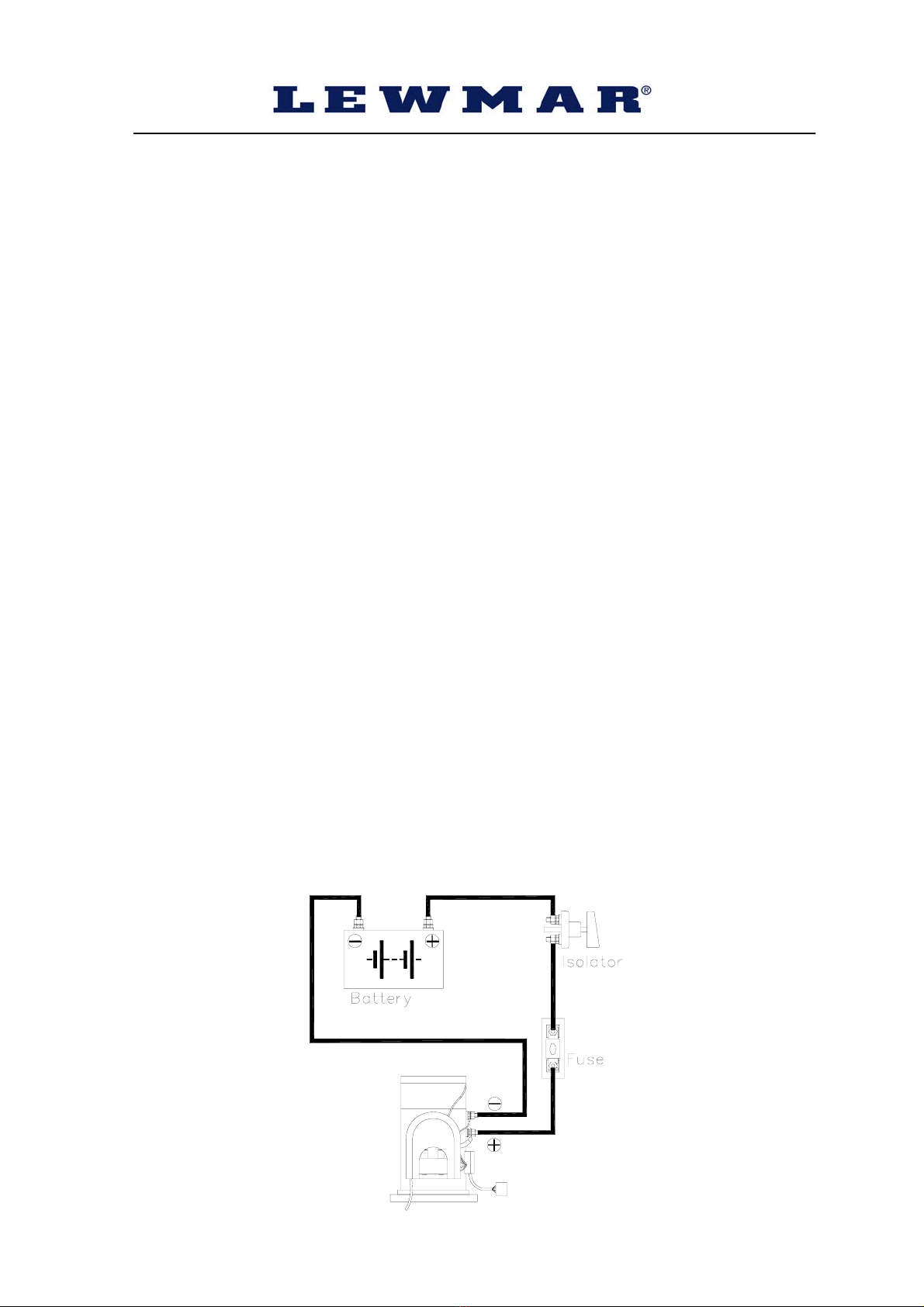

Usually, the hull piece that has been cut out of the hull would be re-used to

provide the Thruster closing plate. This can be attached to the ribs moulded

into the tunnel shroud. The raise lower motor can take a hull piece up to 50kg

(110lbs). If additional bolts are being used, ensure that the bolt heads do not

foul the propeller tips inside the shroud. A landing or register (see diagram

below) should be moulded into the hull cut out, to allow the hull closing piece

to 'locate' when the Thruster is fully retracted. This is to prevent water flooding